The automation of industrial machinery, whether it be in manufacturing, agriculture, logistics, energy, automotive, or unmanned aerial vehicles, promises great gains in resource efficiency, equipment accuracy, and safety. A key enabler of these gains is the identification of the appropriate sensing technologies to enhance the contextual knowledge of the equipment’s condition. To the extent that location or position of the equipment is also a valuable input to the equation, then precision inertial sensors hold the promise of essentially pinpointing location or maintaining accurate positioning. Coupling both the location and the contextual sensor information is of substantial value in those applications where mobility is a factor. In many situations, the determination of position while operating in a complex or harsh environment is of especially critical value. This Internet of Moving Things (IoMT) has many challenges on the path to great efficiency gains, and high performance inertial sensors are helping make the difference.

Sensors Propel Machine Automation

As machinery has evolved from making simple passive measurements, to containing embedded control functions, and now on to fully autonomous operation, sensors are playing an enabling role. Whether for simple measurement supporting offline analysis, or for process control, many such sensors worked sufficiently in isolation. The desire to extract real-time benefits, and the availability of an increasingly wide breadth of sensing types and efficient processing, has brought about important advances in sensor fusion, to best determine context across multiple application/environmental states. Finally, in complex systems involving the interaction of multiple platforms, and requiring knowledge of past system states, advances in connectivity are supporting increasingly intelligent sensor systems, as described in Table 1.

Table 1: Sensor Integration and Connectivity Levels

These intelligent and accessible sensor systems are revolutionizing what would otherwise be mature industries, turning agriculture into Smart agriculture, infrastructure into Smart infrastructure, and cities into Smart cities. As sensors are deployed to gather relevant contextual information in these environments, new complexities arise in database management and communication. Sophisticated fusing is not just required for sensor-to-sensor, but across platforms and time.

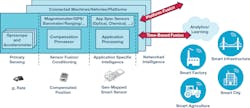

Fig. 1. Integrating toward Location-Aware Industrial Smart Sensing

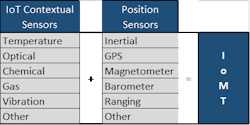

In some cases where mobility is important, geo-locating contextual sensor data is required. In fact, little of the Internet of Things can be considered "static." Equipment in factories, fields, and hospitals is more useful when not fixed to a single location, and an optical sensor on a fixed-location piece of equipment is still likely locally mobile, in that it requires steering/pointing. This Internet of Moving Things (IoMT) fuses contextual and positional data (Table 2), and essentially amplifies the usefulness of the data, and the efficiency gains. As an example, for analyzing yield enhancement opportunities, imagine the difference in relevance of knowing the temperature, moisture, and precise location of an individually planted seed, versus simply knowing the temperature and soil condition of a field of randomly planted seeds.

Table 2: Accurate Positioning Coupled with Context, Enabling the Internet of Moving Things

Inertial Sensors within Smart Machines

Inertial sensors serve two primary functions within most Smart Machines.

- Equipment stabilization/pointing

- Equipment navigation/guidance

This is shown in Fig. 2. While GPS may be considered the navigational aid of choice for most systems due to its ubiquity, for many industrial systems, there exist significant concerns, primarily due to potential blockages. Transitioning to inertial sensing during a GPS blockage is effective, but only assuming the inertial sensors are sufficient quality to provide adequate precision for the duration of the outage. In the case of a stabilization/servo loop, inertial sensors may be relied on in the feedback mechanism to maintain a reliable pointing angle of an antenna, crane platform, construction blade, farming implement, or camera on a UAV. In all of these examples, the purpose goes beyond providing a useful feature. For example, gesture control in a mobile phone, to delivering critical accuracy or safety mechanisms, in the midst of incredibly difficult environments (see Table 3).

Fig. 2: Inertial Measurement Units serve critical stabilization and positioning role in applications where traditional other sensors have limitations

Table 3: Environmentally Challenged Industrial Applications Pose Challenging Requirements to Inertial Sensors

Sensor Quality Matters

There is a myth, or perhaps dream, that Sensor Fusion algorithms can be used to essentially ‘code’ good performance into otherwise marginal sensor technology. Sensor fusion can be used for some corrections, for instance, a temperature sensor to correct for temperature drift of another sensor, or an accelerometer (g) sensor to correct for gravitational effect on a gyroscope. Even in these cases, this actually only calibrates the given sensor to the environment, it does not improve its inherent ability to maintain performance between calibration points, it only interpolates it. A poor-quality sensor typically drifts rapidly enough that without extensive/expensive calibration points, accuracy falls off quickly.

Nevertheless, some amount of calibration is typically desired even in high quality sensors, in order to extract the highest possible performance from the device. The most cost-effective approach to doing this is dependent on the intricate details of the sensor, and a deep knowledge of the motion dynamics (Fig. 3), not to mention access to relatively unique test equipment. For this reason, the calibration/compensation step is increasingly seen as an embedded necessity from the sensor manufacturer.

A second significant step in the path of converting basic sensing outputs into useful application-level intelligence, is state-driven sensor handoff. This requires expansive knowledge of the application dynamics, as well as the capabilities of the sensors, in order to best determine which sensor can be relied on at any given point in time.

Fig. 3: Extracting Valuable Application-Level Information from Inertial Sensors Requires Sophisticated Calibrations and High Order Processing

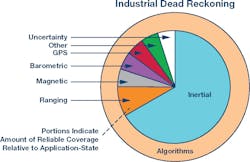

A conceptual example of the role of sensor fusion in an industrial application is illustrated in Fig. 4. Here, for a precision-driven industrial application, a careful selection of sensors has been done to support an expected need to operate within high potential GPS blockages, and potentially difficult magnetic and other environmental disturbances. For this reason, the infrastructure-free nature of inertial sensors is most heavily relied on, with other sensing aids chosen to support specific environmental challenges, and to help correct for any long term inertial drift. While it is preferable to plan sensor selection to allow precise tracking under all conditions, this is practically impossible, thus the small segment of "uncertainty" still retained in the scenario planning. The algorithms exist for valuable sensor calibrations, as well as to manage the sophisticated sensor-to-sensor hand-off driven by the application state.

Fig.4: Sensor Fusion Algorithms Rely on Precision Sensors, Properly Chosen to Support Specific Application Environment

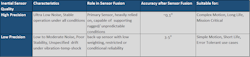

Ultimately, the end application will dictate the level of accuracy required, and the quality of sensor chosen will determine whether this is achievable. Table 4 contrasts two scenarios, illustrating the significance of sensor choice to not only the design process but to the equipment precision. A low-precision sensor may in fact be suitable if it is only to be relied on in limited instances, and if the application has tolerance for error; in other words if it is not safety- or life-critical, or if relatively imprecise accuracy is good enough.

Most consumer-level sensors have low noise and perform adequately in benign conditions, but they are not suitable for machinery subject to dynamic motion. For example, with a low performance inertial measurement unit, vibration cannot be separated from the simple linear acceleration or inclination measurement that is desired. To achieve accuracy of better than 1 degree, while operating in an industrial environment, the selection focuses to sensors which are designed specifically to reject error drift from vibration or temperature influences. Such a high-precision sensor is then capable of supporting a larger span of the expected application states, and over longer time periods.

Table 4: Industrial Applications with Complex, Mission Critical Requirements Rely on High-Precision Sensors

High-Performance Inertial sensor

Designing for performance does not have to be exclusive of designing for efficiency in cost, size, and power. However, designing a micro-electro mechanical (MEM) structure with a primary goal of cost reduction, will typically sacrifice performance, sometimes significantly. Some simple choices for reducing cost, such as less silicon mass and plastic encapsulated consumer packaging, are largely detrimental to MEMs performance.

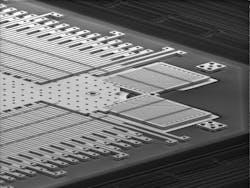

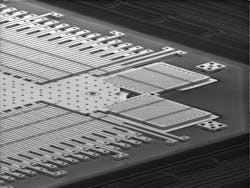

Extracting accurate and stable information from a MEMs device such as the one illustrated in Fig. 5, requires strong signal-to-noise driven by silicon area and thickness. In addition, a device like this would need to minimize stress imposed to the silicon from the selection of component packaging through to system level enclosures. With end-use performance requirements in mind at the onset of the sensor definition, the silicon, integration, packaging, and test/calibration approaches can be optimized to maintain native performance and minimize cost even under complex environments.

Fig. 5: Micro Electromechanical Structure Used for Precision Motion Determination

Table 5 shows performance demonstrated in a mid-level industrial device, in comparison to a typical consumer sensor which may be found in a mobile phone. (Note that higher-end industrial devices are also available, which are an order of magnitude better than those shown.) Most low-end consumer devices do not provide specifications for parameters such as linear acceleration effect, vibration rectification, angular random walk, and others that actually can be the largest error sources in industrial applications.

Industrial sensors of the type illustrated in Fig. 5 are designed for use in a scenario anticipating relatively rapid or extreme movement (2,000 degree-per-second, 40g), where a wide bandwidth sensor output is critical to enable best discrimination of signal. Minimum drift of offset during operation (in-run stability) is desired to reduce the reliance on a larger suite of complementary sensors to "correct" performance. In some cases, minimization of turn-on drift (repeatability) is critical in applications that cannot afford the time required for back-end system filtering corrections. Low noise accelerometers are used in cooperation with gyroscopes to help distinguish and correct for any g-related drift.

The gyroscope sensors have actually been designed to directly eliminate the effect of any g-event (vibration, shock, acceleration, gravity) on the device offset, providing a substantial advantage in linear-g. And, via calibration, both temperature drift and alignment have been corrected. Without alignment correction, a typical multi-axis MEMs device, even when integrated into a single silicon structure, can be misaligned to the point of being the major contributor to an error budget.

Table 5: Industrial MEMs devices Offer Extensive Characterization of All Known Potential Error Sources, and Typically Achieve Order of Magnitude and Better Precision

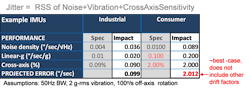

While noise has become less of a distinguishing factor among sensor classes in recent years (both low or high end sensors have relatively low noise), parameters such as linear-g effect and misalignment which are most costly to improve, either through silicon design approach or through part-specific calibration, become noise adders in any application beyond simple or relatively static motion determination. Table 6 provides a use-case example comparing an actual industrial MEMS inertial measurement unit (IMU) to a consumer IMU. Both industrial and consumer IMUs have relatively strong noise performance. However, the consumer device is not designed or corrected for vibration or alignment.

Table 6 shows the device specification, and its impact on the error budget based on the stated assumptions. The total error is a root sum square of the three illustrated error sources: noise density, linear-g, and cross axis. Linear-g and cross-axis (misalignment) dominate the error in the case of the consumer device, whereas the industrial device is better balanced. Ultimately, a minimum of 20X difference in performance is realized, without looking at additional potential error sources of the less rugged consumer product.

Table 6: In Dynamic Motion, Linear-g and Alignment Become Dominant Error Sources. (Industrial devices balance all specifications for low overall error.)

System Trade-offs

The majority of complex motion applications require a full IMU (three axes of both linear acceleration and angular rate motion) to adequately determine positioning. IMU functionality is available today in both chip-level (consumer) form, and in module level integration (industrial). (See an example of Industrial IMU in Fig. 6.) Though logically it may seem that the consumer chip-level IMU is more advanced in system integration, in fact, the opposite is true when the end goal is accurate motion determination in a complex industrial environment. In the case of the industrial IMU, high performance is available out of the box. The same high performance is reliably attained over the life of the application, with minimal requirement, if any, for in-system correction. The consumer IMU, though seemingly fully integrated and complete, in fact requires significant added time, integration, and cost (see Fig. 7) to attempt to achieve similar levels of performance (typically not even possible), and likely still never achieves equally reliable operation.

Fig. 6: Six Degree of Freedom Inertial Measurement Unit, ADIS16460, Specified for Precision Even within Complex and Dynamic Environments

Fig.7: Low Component Cost of Consumer Sensors Becomes Burdened by Necessary System-Level Expenditures, and Ultimately Reliability and Performance Tradeoffs

Location-aware industrial smart sensors are enabling tremendous efficiency gains within machine automation. Accuracy and reliability at the system level is primarily a function of the core sensor quality, not the systems and software wrapped around it. Nonetheless, the overall integration, embedded software, and connectivity of the approach, when built around quality sensors, allows intelligent sensing solutions which can greatly enhance the quality and utility of information, without sacrificing equally important safety and reliability.

About the Author

Bob Scannell

Business Development Manager

Bob Scannell is a business development manager for Analog Devices’ Inertial MEMs Products. He has been with ADI for 18 years in various technical marketing and business development functions ranging from sensors to DSP to wireless. Previously, he worked at Rockwell International in both design and marketing. He holds a BS degree in electrical engineering from the University of California, Los Angeles, and an MS in computer engineering from the University of Southern California.