Project Mercury and SpaceShipOne: Two Different Missions that Shaped the Space Race (Part 1)

Key Highlights

- The flights of NASA’s Faith 7 Mercury and X-Prize Foundation’s SpaceShipOne were milestone events in the history of space exploration.

- Although they served very different objectives and were separated by four decades of technological advances, each project laid the foundations for the more advanced missions that followed.

- Surprisingly, Mercury and SpaceShipOne also shared several important elements that contributed to their missions’ success.

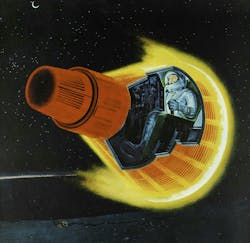

More than six decades ago, Alan Shepard and his Mercury capsule roared into the sky atop a modified version of a WWII-era ballistic weapon.1,2 (Fig. 1, left). After achieving an altitude of 116.5 miles, Freedom 7's 15-minute, 302-mile suborbital flight ended in a successful splashdown in the Atlantic, making him the first American astronaut to achieve spaceflight.

Roughly 40 years later, Mike Melvill piloted SpaceShipOne (Fig. 1, right), a privately funded, air-launched, rocket-propelled vehicle to the edge of space, becoming the world’s first licensed commercial astronaut.3

Although they served very different objectives and were separated by four decades of technological advances, each project laid the foundations for the more advanced missions that followed. Surprisingly, Mercury and SpaceShipOne also shared several important elements that contributed to their missions’ success.

Two Very Different Spacecraft — Or Were They?

At first glance, the Mercury capsule and SpaceShipOne appear to have had little in common.

Mercury’s compact, conical form factor shared many of the design features of the reentry vehicles developed to carry nuclear warheads to their targets. It sat atop the same Redstone4 and Atlas5 ballistic missiles that had been repurposed to put the first Americans into space.

In contrast, many design and assembly techniques in SpaceShipOne’s sleek carbon-composite airframe borrowed heavily from materials and technologies developed by “amateur” aerospace enthusiasts for constructing their homebuilt aircraft.

Rather than relying on a conventional booster rocket, SpaceShipOne was carried on the first leg of its journey to space beneath the wings of another aircraft. Moreover, instead of returning to Earth in the predetermined ballistic arcs used by Mercury flights, SpaceShipOne’s aerodynamic surfaces allowed it to reenter the atmosphere more gently and glide to an airport under its pilot’s control.

>>Check out Part 2 of this series

A closer look, however, reveals that both designs were minimalist approaches to getting humans into space as quickly and safely as possible using the resources available at the time. And, as history shows, both programs’ successes were made possible by equal measures of ingenuity, persistence, and audacity.

Pre-Project Mercury: Politics and the Space Race

Project Mercury was as much a product of the political pressures surrounding the 1960s-era “space race” between the U.S. and the USSR as the technological advances that made it possible.

In the early 1950s, well before the space race with Russia turned hot, the U.S. Air Force already began developing its own space program. Most of their efforts focused on creating a reusable “spaceplane” using knowledge gained from earlier experimental aircraft. Among the most promising concepts was the X-15B,6 a more advanced version of highly successful X-15,7,8 a rocket-powered hypersonic aircraft (Fig. 2).

The X-15 had already flown over 200 missions to near-space altitudes (as high as 264,000 feet/50 miles) while achieving speeds in excess of 4,500 mph.8,9 So, its successor, the X-15B, was the natural choice to lead the U.S. crewed space program. NASA considered several novel options to replace the B-52 that had served as a carrier aircraft for the X-15.

The initial study called for either a modified XB-70 supersonic bomber,10 or an XM-64 Navajo cruise missile,11 to bring the X-15B to the stratosphere before it would fire its internal rocket engine and climb into orbit. At the end of its mission, the same engine would be used as a “retrorocket” to slow the craft enough to break orbit. As a result, gravity was able to pull the X-15 back into the atmosphere where it could glide back to Earth for landing and refurbishment.

The Air Force’s X-15B space plane appeared to be a perfect complement to the U.S.’s ambitious timetable, laid out in 1955, for launching its first artificial satellite in the 1957-1958 timeframe. Unfortunately, those plans were sidelined by the political realities that arose in late 1957, after Russia stunned the world with its unexpected launches of Sputnik I on October 4, and Sputnik II on November 3.

Although America quickly stepped up its efforts, it took until January 31, 1958, before managing to launch its first artificial satellite, the Explorer 1. By then, it was becoming apparent that Russia stood a good chance of putting a man into space much earlier than the five to 10 years forecast for the U.S. space program to develop a complex, reusable crewed vehicle like the X-15B.

Two Designs Born Under Pressure

Under the newly authorized National Aeronautics and Space Administration (NASA), the U.S. initiated Project Mercury to close the gap as quickly as possible. Running from 1958 through 1963, the program aimed to create the simplest possible spacecraft capable of carrying an astronaut and the equipment they’d need to survive the flight. Moreover, the Mercury capsule had to be light (around 2,500 lbs) so that the relatively small rockets available at the time could launch it.

Similarly, competition was key to SpaceShipOne’s genesis. In this case, the competition was created by the Anasari XPrize, a $10 million reward to the first team to successfully launch and recover a reusable crewed spacecraft beyond the 100-km Karman Line, twice within two weeks. Created in 1996 by entrepreneur Peter Diamandis, the XPrize competition attracted 26 teams, ranging from volunteer groups of amateurs and academics to well-funded consortiums backed by large aerospace corporations.

The winner, the Tier One Project (aka Mojave Aerospace Ventures), was led by the Scaled Composites Corp., based in Mojave, Calif., funded by tech billionaire Paul Allen.

Mercury Overview

In late 1958, the U.S. government’s fear of falling behind the Russians drove NASA to impose an aggressive schedule on the Mercury program. This included the production of the capsules that would be used for the first crewed flight on May 5, 1961, and five subsequent missions, as well as several engineering prototypes.1

Designed and integrated by McDonnell Aircraft, the vehicle’s compact structure provided just enough room the engineers needed to squeeze in an astronaut, their space suit, and the minimum complement of life support, communication, propulsion, and guidance systems to support brief forays into space (Fig. 3). Much like the X-15, the capsule was equipped with small hydrogen-peroxide-powered thrusters that could orient the craft while in orbit.

At the end of its mission, the astronaut would execute a de-orbit maneuver using a pack of three small solid-propellant retrorockets attached to its blunt end to slow the craft enough to be captured by Earth’s gravity. The cone-shaped vehicle would reenter the atmosphere leading with its blunt circular base

Protection was provided by an ablative heat shield that used the same principles and technologies originally developed to enable ballistic nuclear warheads to survive the fiery conditions they would encounter on the way to their targets (Fig. 4). The remainder of Mercury’s aluminum and titanium structure was sheathed in panels made of Rene 41, a heat-resistant nickel-based alloy.1,12

Following its hypersonic dive through the upper atmosphere, Mercury would be falling slowly enough to deploy three parachutes from its nose to further slow its decent. This would be followed by a relatively soft water landing and recovery by helicopters that would deliver the capsule and its pilot to a nearby ship.

We’re Pilots, Not Passengers!

In keeping with their directive to keep the spacecraft as simple as possible, Mercury’s designers initially assumed the humans it carried would be passive “cargo.” The plans was to have the capsule primarily controlled from the ground via a network of tracking and communications stations.1

As a result, the initial designs didn’t include a full complement of manual flight controls or the electronics capable of making the complex calculations required for reentry (retrofire times and firing attitude). Instead, they relied on ground-based computers to calculate all of the commands, which would be transmitted to the spacecraft.

The same minimalist design philosophy also led to the absence of any sort of window or porthole in early designs of the capsule. The astronauts, refusing to be treated like the two chimpanzees NASA flew during the early stages of the test program,13 strenuously objected. After numerous heated debates, NASA relented and directed the addition of improved backup manual controls as well as viewing windows and a periscope system that the astronauts could use for both observation and navigational tasks.

These changes proved to be fateful and fortuitous, saving at least one Mercury flight from a tragic ending.

SpaceShipOne Overview

SpaceShipOne’s prime contractor, the Tier One Project, was founded by Burt Rutan, who got his start creating designs for homebuilt aircraft. Scaled Composites had decades of experience using unconventional aerodynamic designs, advanced materials, and new manufacturing processes to develop prototypes of high-performance aircraft and other vehicles for commercial and military applications.

The company’s prior achievements included several record-breaking aircraft such as the Stratolaunch, the world’s largest aircraft, and Voyager, which made history with the first nonstop, unrefueled flight around the world in 1986.

Scaled Composites had limited experience with rockets, so the team leaned into its existing strengths to meet the competition’s tight schedule constraints. The result was a remarkably simple spaceplane and launch system built largely using the materials, technologies, and manufacturing techniques they were already familiar with.

Peter Siebold, Vice President of Tier One Flight Ops, proudly noted that Scaled Composites used a small team of fabricators, engineers, and pilots to develop a space vehicle, a carrier aircraft, a rocket motor, and an avionics system from scratch in three years to accomplish the mission.

In contrast to Mercury’s cramped, conical metallic airframe, SpaceShipOne’s fuselage was a cigar-shaped structure, fabricated primarily with graphite/epoxy composite materials. Measuring a relatively roomy 5 feet in diameter, the structure enclosed a pressurized three-seat crew cabin, a hybrid rocket motor, and its oxidizer supply.3 The craft sported a set of short, wide wings each with its own vertical tail boom and horizontal stabilizer assemblies.

And, unlike its predecessor, SpaceShipOne was designed from the outset to be flown by its pilots much like a conventional aircraft. For most of the mission, the pilot would fly the craft using manual aerodynamic controls. During the brief time it would spend outside the atmosphere, they would adjust the craft’s orientation using a redundant set of cold gas thrusters.

Both sets of controls reflected the project’s emphasis on simplicity and founder Burt Rutan’s inherent distrust of excessive automation. This was most evident in the aircraft-style mechanical stick and pedal system that used cable-and-rod linkages to actuate the craft’s elevons and its separate upper and lower rudders.

The only flight control system that had any level of automation was the trim system. It had a selectable stability augmentation mode to address the complex dynamics of rocket-propelled supersonic flight that the craft would encounter during launch. Once its boost phase was over, the trim system reverted to a mechanical cable-and-rod linkage that was also used during its subsonic reentry glide.

After reaching the top of its suborbital arc, the pilots would configure SpaceShipOne for a gentle reentry by tilting its wings to form an aerodynamically stable high-drag "feathered" shape. It greatly reduced the need for active attitude control while the craft descended through the thin upper atmosphere (Fig. 5).

Below 50,000-60,000 feet, the pilots would lower SpaceShipOne's tail booms, allowing the craft to behave like a conventional glider and land on the same runway its carrier aircraft launched from.

Part 2 of this saga looks at the two missions’ radically different approaches to launching their spacecraft before exploring the important role the skills and ingenuity of their pilots played in their success.

References

1. Loyd S. Swenson Jr., James M. Grimwood, and Charles C. Alexander, “This New Ocean: A History of Project Mercury,” NASA SP-4201, 1966.

2. Elizabeth Howell, “Project Mercury: America's 1st crewed space program,” Space.com, Nov. 2024.

3. Scaled Composites, “Twenty years since breaking a boundary: SpaceShipOne,” June 2024.

4. Andrew J. LePage, “Old Reliable: The story of the Redstone,” The Space Review, May 2, 2011.

5. Atlas (SM-65), “Warren ICBM and Heritage Museum.”

6. L Parker Temple III, “X-15B: Pursuit of Early Orbital Human Spaceflight, Air Power History.” Spring 2008, pp 28-41.

7. Dennis R. Jenkins, “X-15: Extending the Frontiers of Flight,” NASA, June 2007, SP-2007-9-001-HQ, ISBN: 978-0-16-079285-4.

8. Milton O. Thompson, “At the Edge of Space: The X-15 Flight Program,” Smithsonian Books, 1989, ISBN 13: 1588340783.

9. Michelle Evans, “The X-15 Rocket Plane Flying the First Wings Into Space, Flight Log," 2020, Mach 25 Media.

10. Dryden Flight Research Center, XB-70 Valkyrie, NASA Facts, Document # FS-2003-07-084 DFRC.

11. Tony R. Landis, Navaho Missile Program: Part 1 and Part 2, Department of Defense Media, 2002.

12. “Mercury reentry heat shields; material composition, manufacturing process and explanation of all those concentric ridges?,” 2021, Space Exploration StackExchange.

13. Eric Betz, “A Brief History of Chimps in Space,” Discover Magazine, April 2020.

>>Check out Part 2 of this series

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.