Hyundai’s 2-Stage Motor System: A Global EV Game-Changer?

What you'll learn:

- Hyundai has developed an innovative system that expands the EV’s usable voltage range by increasing voltage utilization.

- The "6 plus 6" configuration increases the voltage that can be supplied to the motor by up to 70%.

- Solving the size and weight issue via in-house-designed power modules.

As electric mobility continues to evolve, innovations like the Hyundai Motor Group’s 2-Stage Motor System promises to simultaneously deliver high efficiency in everyday driving and instantaneous high power when accelerating. Up until now, that latter characteristic was considered unattainable.

First a bit of background. In an EV, power output is determined by voltage and current. To increase the drive motor’s power, you can increase the battery voltage or adjust the motor’s characteristics to increase current.

The downside is that increasing current makes the motor-drive system larger and heavier, and heat management becomes more difficult. Also, when designed mainly for high power output, efficiency drops significantly during everyday city driving.

Electric vehicles don’t just move with a motor alone. The motor-drive system consists of three key parts: the motor, reducer, and inverter (Fig. 1). The motor generates rotational force (torque), the reducer transfers that torque to the wheels, and the inverter converts the battery’s DC power into AC power for the motor.

An EV’s power output depends on the voltage and current the battery can deliver to the motor (or motors) via the inverter. Traditionally, increasing current resulted in a heavier propulsion system and greater heat-management challenges. Motor systems optimized for high output in this way often compromise efficiency during normal driving.

Rethinking the Inverter by Increasing Voltage Utilization

Fortunately, technology can render assistance. Hyundai Motor Group’s R&D approached this challenge by rethinking the inverter, which consists of semiconductor-based switches. When the switches are closed, current flows; when they’re open, it doesn’t.

As AC current flows through the motor’s coils, it creates a magnetic field that constantly changes as the current alternates. This shifting magnetic field pushes and pulls the magnetized rotor at the motor’s center, causing it to spin. This in turn moves the vehicle forward.

To overcome previous limitations, Hyundai has developed an innovative system that expands the usable voltage range by increasing voltage utilization. The automaker solved the size and weight issue via in-house-designed power modules. Each module houses the power semiconductor switches and provides packaging that ensures heat dissipation and electrical insulation, resulting in more precise coordination and control.

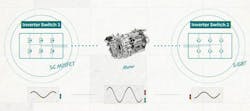

Conventional inverters use six switches, often employing silicon-carbide (SiC) semiconductors — a high-efficiency but costly material. Hyundai’s 2-Stage Motor System features a dual inverter structure equipped with 12 semiconductor switches in a “6 plus 6” configuration, doubling the conventional switch count (Fig. 2). One set of six switches utilizes SiC semiconductors for high efficiency, while the other set uses silicon (Si) semiconductors to support high-power conditions.

The voltage range was expanded since doubling the number of inverter switches connected to a single motor allowed the company to apply higher voltage levels. The SiC switch set is only used to maintain high efficiency. In high-speed or high-output power conditions, both switch sets operate together.

I won’t tease you, here’s the data: According to Hyundai, the 6 plus 6 configuration together with multiple control strategies increases the voltage that can be supplied to the motor by up to 70%, enabling a higher power output without compromising efficiency (Fig. 3). A transfer switch enables flexible operation across various driving conditions — using one set of six switches or both sets of 12 — delivering balance between performance and efficiency.

Control Architecture

Doubling the number of switches necessitated not just a hardware upgrade — it required a complete redesign of the control system. A conventional six-switch inverter divides them into upper and lower sets for three phases, operating in eight different combinations under strict switching rules.

When the number of switches doubles, the combinations increase eightfold, requiring much more precise control and a new level of coordination between switches becomes necessary. If the system moved in steps, the car would feel like it’s jerking or stuttering.

Advanced control is needed to smooth the voltage vectors. The Hyundai Motor Group’s system controls 12 switches simultaneously, expanding the usable voltage space.

One module fixes six switches in a six-step configuration, while the other controls the remaining six through 64 possible combinations.

Hyundai Motor Group developed proprietary control algorithms that it said ensures seamless transitions between these two modes. The system operates using Hyundai Motor Group’s smart dual-mode control, split across the following conditions:

- City driving: Uses a single set of switches for optimal efficiency.

- High performance: Activates both sets of switches to deliver maximum power.

The system employs a transfer switch to shift between modes, ensuring strong power when accelerating and high efficiency during long-distance driving.

Creating a Compact Design

The inverter’s size depends on its built-in semiconductor power modules. Hyundai Motor Group integrated nine power modules into three and cooling was improved from single-sided to a double-sided setup, reducing size and weight while maintaining durability. This enhancement allows for higher power density within a smaller package, enabling high output without increasing overall dimensions. Thus, the 2-Stage Motor System can be practical for mass production.

The system is already powering Hyundai EVs, such as the Hyundai IONIQ 5 and IONIQ 6, and it’s expected in the IONIQ 9 and new NEXO FCEV (see lead image), a hydrogen-powered fuel-cell electric vehicle.

This innovation earned the Presidential Award at the 2024 Korea Technology Awards, the nation’s highest honor for technological excellence.