48-V Systems: A Sweet Spot for Traditional and Mild-Hybrid Vehicles

What you'll learn:

- Why manufacturers, especially in Germany, are embracing 48 V.

- The huge opportunities for electrification in the 48-V platform.

- The challenges, especially in EMC, from higher-voltage systems and how to overcome them.

For more than a decade, the automotive industry has anticipated a shift in low-voltage architectures. That future has now arrived. Across Europe — and particularly in Germany — 48-V power systems have moved from experimental curiosity to mainstream electrical architecture.

American, Korean, and Chinese OEMs are rapidly following, treating 48 V not as an optional subsystem, but as a fundamental inflection point comparable to the adoption of CAN bus, the transition to 800-V traction drives, and the migration from brushed machines to permanent-magnet BLDC technology.

Why Did 48 V Emerge First in Germany?

Although 48-V architectures appear new in production vehicles, the concept has circulated within German automotive engineering circles for nearly two decades. Internal discussions at Bosch, Continental, Daimler, and ZF reportedly began long before the wider industry took notice. These teams recognized an important cultural and technical shift: The alternator was no longer a simple electromechanical component — it had become an integrated rotating power-electronics system.

As integrated belt-starter-generator (iBSG) systems matured, the limitations of 12-V architectures became evident: 12 V can’t deliver high power without untenable current levels. Harnesses, fusing, contactors and connectors become large, costly, and thermally constrained at 250 to 350 A.

On the other hand, 48 V provides 4X the power at the same current, enabling significantly higher instantaneous energy transfer without excessive copper. Moreover, 48 V remains below the 60-V boundary that approximates safe, “low-voltage” safety practices. [While 60 V DC is a common limit for "extra-low voltage" (ELV) or "touch-safe" classifications in dry conditions, high-current systems (e.g., large battery banks for electric vehicles or microgrids) even at 48 V can still pose a significant hazard if proper safety measures are ignored.]

Thus, 48 V created an attractive design space — a higher-power bus without the regulatory and procedural burden of full high-voltage EV architecture. Germany’s OEM–Tier-1 ecosystem aligned early, defined the voltage class, standardized its interfaces, and built supply chains around it.

>>Download the PDF of this article

By the time Korean and Chinese manufacturers fully engaged (especially between 2018 and 2022), 48-V systems were already shipping in cost-optimized form. What had once been a niche concept became a de facto industry standard.

No other voltage satisfies these constraints simultaneously. While 36 V could theoretically fit, the supply chain has converged on 48. At the other end, 72 V offers efficiency advantages but crosses into HV regulatory friction.

In this sense, 48 V resembles the emergence of 3.3 V as a foundational logic level. It’s not an ideal voltage, but the most practical equilibrium point considering component availability, safety rules, and global manufacturing inertia.

How Does 48 V Actually Increase Complexity?

The headline benefits of 48 V — lighter wiring, smaller motors, improved transient performance — are real but incomplete. With 48 V, power-electronics complexity increases significantly, especially in thermals, switching behavior, and EMC.

Thermal and Power-Density Coupling Intensifies

At 48 V, power stages transition into regimes where semiconductor and packaging effects dominate. FET die shrink and switching speeds increase, but thermal robustness decreases while package parasitics strongly influence efficiency and overshoot.

To reduce magnetics size, switching frequencies trend upward (80 to 150 kHz, sometimes 200 to 300 kHz), tightening EMI constraints.

This isn’t simply 4X the power at 12-V current levels. It’s 4X the power with higher edge rates and greater sensitivity to layout and parasitics.

Layout Becomes a Core Competency

Engineers accustomed to slower 12-V switching behavior may underestimate the importance of loop inductance. Mild-hybrid inverters and DC-DC converters increasingly resemble small industrial servo drives packaged for automotive thermal and environmental conditions. Thus, design priorities become loop minimization, return-path control, and Kelvin-source gate driving, which uses a dedicated source pin on a 4-pin MOSFET package to isolate the gate-drive return from the main power loop.

Separating the driver source from the high-current source path eliminates voltage drop and switching-noise effects caused by shared source inductance. This, in turn, improves timing accuracy and overall switching performance.

Boost and Buck Stages Become Chassis Infrastructure

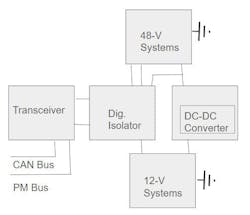

A 48-V vehicle isn’t a single-rail architecture. Most platforms now include multiple 48-V “islands,” multi-kilowatt 48- to 12-V converters, optional 48- to 800-V transient interfaces, and embedded HV/48-V coordination logic.

In other words, DC-DC converters are evolving into infrastructure elements, analogous to distributed power modules in data centers. In this reality, the architectural mindset shifts from accessory power distribution to structured, multi-layered energy management.

How Does 48 V Lead to Smaller Electromechanical Components?

Copper reduction is often cited as the main benefit of 48 V, but the most meaningful mass savings come from magnetic components. Motors scale down more aggressively than harnesses. Inductors, chokes, and filters shrink more aggressively than motors, and mechanical packaging flexibility improves thanks to increased power density.

Torque density depends on topology, materials, and cooling — not voltage alone. However, 48-V machines can use lower-gauge windings and achieve higher copper fill with reduced RMS losses. When paired with optimized stator geometries and lamination design, substantial mass savings follow.

Critical components benefiting from 48 V include differential-mode chokes, power-factor-correction (PFC) inductors (where applicable), stator windings on BLDC drives, EMI/RFI filters on 48- to 12-V converters, and high-side EMI suppression chokes.

The net effect is a meaningful decrease in weight and volume across the power-electronics and electromechanical stack.

How Can Robust Designs be Distinguished from Fragile Ones in 48 V?

Tier-1 suppliers reportedly now apply a stricter evaluation framework to 48-V hardware. Successful programs exhibit:

- Treatment of high-di/dt loops as RF structures, not power paths.

- Gate-drive parasitic simulation performed before PCB layout.

- MOSFET selection co-optimized for thermal interface area.

- No assumption that module-level EMC equals vehicle-level EMC.

- Pre-compliance EMI testing prior to layout freeze.

- Surge-and-transient modeling that accounts for the nonlinear stress curves of modern FETs.

- Recognition of the 48- to 12-V converter as the functional successor to the legacy alternator regulator.

- System design “from the harness inward” rather than “from the PCB outward.”

The last point is crucial. At 48 V, the harness becomes an active electromagnetic element, influencing emissions susceptibility, surge behavior, and transient-voltage-suppression (TVS) and clamp-strategy requirements.

This marks a departure from the largely resistive, electrically benign 12-V harnesses of the past

What are the Hidden Organizational Challenges in 48 V?

Technically, 48 V sits between two established engineering cultures: the 12-V accessory/body-electronics domain and the high-voltage (400 to 800 V) traction domain.

Because it fits neatly into neither, ownership becomes ambiguous. Some OEMs place it under chassis electrification, others under body electronics, and others under propulsion.

German manufacturers gained an early advantage by assigning 48-V systems to powertrain engineering, aligning them with propulsion, energy management, and EMC. This organizational clarity accelerated toolchain development, safety analysis, and integration maturity.

Is 48 V Really a Complete Voltage Class?

From an engineering standpoint, 48 V isn’t a transitional architecture. It’s a fully characterized voltage class with unique failure modes, distinct EMC characteristics, its own magnetics-scaling laws, and a specific reliability and protection envelope.

OEMs that treat 48 V as a structured platform are advancing quickly, while those that treat it as an “oversized alternator” may continue to experience integration and EMI challenges.

As electrified actuators, e-boost systems, active suspension modules, and energy-recovery technologies proliferate, 48 V is becoming the structural backbone of the automotive power stack:

- 12-V legacy electronics

- 48-V functional power backbone

- High-voltage traction (400 to 800 V)

Its global adoption stems from a simple design truth: 48 V is high enough to unlock meaningful electrical and mechanical gains, and low enough to avoid the full overhead of high-voltage EV safety frameworks.

For design engineers worldwide, this voltage class represents one of the most active areas for innovation in power electronics, magnetics, packaging, and EMC. And, some believe over the next five years, most of the incremental capability in mild-hybrid and electrified subsystems will be built on this foundation.

References

>>Download the PDF of this article

About the Author