Behind the Engineering that Goes into a Leg Prosthesis

This file type includes high resolution graphics and schematics when applicable.

In 1919, a German prosthetist named Otto Bock surveyed the results of the bloody butchery of World War I and set out to improve the functionality of the artificial limbs that wounded soldiers and civilians needed to carry on their lives. His first innovation was to make the production of artificial limbs into a production-line operation, rather than a custom process for each amputee, as it had been in the past. Needless to say, the rest of the 20th Century provided more than ample opportunity to refine and innovate the mass-produced, fittable, artificial limb.

Mr. Bock died in 1960. Today, Otto Bock Healthcare, the company named after him, is a global organization headquartered in Duderstadt, Germany, with engineering facilities worldwide, including Minneapolis.

The company is known, among other things, for its “C-Leg” a microprocessor-controlled above-the-knee prosthesis (Fig. 1). There are numerous videos on the Web showing men and women who wear the leg riding bicycles, enjoying strenuous sports, and otherwise living full lives. The engineering story behind the C-Leg is intriguing.

Re-Closing the Feedback Loop

Our human, upright-stance, two-legged locomotion shouldn’t be possible. It’s a constant battle against gravity, based on sensors located everywhere from our ears to our limbs to our toes. A request for a movement is initiated by the brain, which sends impulses through the spinal cord and nerves to the muscles, particularly, the calf muscle. For most of us, muscle activity and nerve stimulation are constantly interacting at about 20 times a second.

To attempt to duplicate at least part of this control system, in the C-Leg, pressure sensors in the leg’s knee and ankle supply information to a microprocessor. Based on this information, a program running on an RTOS in the C-Leg’s microprocessor controls a system of hydraulics in the leg.

In the software, walking is divided into a “stance” phase and a “swing” phase. During the stance phase, the primary task is to stabilize the leg, so that it can support the body weight when the user is not yet in motion.

The swing phase, when the user is in motion, places a greater load on the microcontroller. The prosthetic lower leg must be controlled as it comes off the ground, swings through its arc, at the pace set by the user, and is then slowed down in preparation for the next step.

In the stance phase, a C-Leg employs hydraulic damping to provide stability. It exits this state and enters the swing state when two criteria are met simultaneously: first, the knee must be fully extended, and second, approximately 70% of the body weight of the prosthesis wearer must be supported by the on the natural leg.

It’s All About the Knees

The C-Leg’s microprocessor-controlled knees are intended to function much like those in a human leg. When the software in the microprocessor receives the sensor information, it has sufficient information to determine exactly where the knee is in the walking or gait cycle. The algorithm is based on data the company collected by analyzing the walking techniques of literally thousands of people. With that information reduced to an algorithm, the microprocessor can anticipate what the leg needs to do moment by moment. This was a breakthrough by Otto Bock Healthcare. It made the prostheses proactive, rather than reactive.

For example, in a sound leg, at the end of a swing phase, just before the heel scrapes the ground, the quadriceps and hamstrings simultaneously contract and prepare for loading that will occur at heel-strike. This prevents the knee from collapsing and allows it to act as a shock absorber while also creating a smooth, efficient gait. The software and pneumatic system in the artificial leg is able to emulate this.

In finer detail, what happens is this: There are two sensors in the prosthesis, one near the ankle and one at the knee joint. They provide the microcontroller with a constant stream of information, updated 50 times a second, about the user's gait and environment. The algorithm in effect enables the C-Leg to anticipate the demands about to be placed on the system and adjust resistance to leg flexion and extension.

Mechanically, it’s more complicated: Based on information from the sensors, the microprocessor-controlled servo-motors open and close valves in the hydraulic channels, increasing or reducing resistance in the knee. These channels can be engaged alone or simultaneously, similar to the large muscles of the leg, to create the appropriate resistance no matter where the user is in the gait cycle. Because each C-Leg user is unique, the practitioner will use Otto Bock software designed specifically for the C-Leg to set special resistance parameters.

The company’s BionicLink system takes advantage of Bluetooth technology, so that the user or a prosthetist can set semi-permanent system parameters tuned to the wearer’s physical characteristics. The various parameters allow the C-Leg to “predict” where the user will be, moment to moment, and enable it to function proactively. The link also allows the wearer to switch among parameters dynamically, in order to adapt to terrain or the type of physical activity he or she is involved in.

Based on sensor information, during the swing phase, the microprocessor anticipates when the leg is about to make heel contact, enabling it to calculate the resistance parameters that will be needed for stance-phase security. With that calculation, it can instantaneously adjust the knee’s flexion valve to adjust resistance in a way that conforms to the user's gait pattern and the current environment.

Then, at the end of each stance phase, the microprocessor recognizes forefoot pressure in conjunction with a straight knee and opens the flexion valve to prepare for swing phase.

The sophistication of the gate cycle part of the algorithm even allows for “stance flexion,” or the natural flexing of the knee that normally occurs after heel contact in a sound leg. This acts like a shock absorber and provides the user with a more natural gait while simultaneously helping him or her expend less energy.

Another aspect of the algorithm is that it restricts the C-Leg from swinging freely unless two criteria are met: the knee must be fully extended and there must be at least 70% of the user's weight on the forefoot. This is important because, if the user starts to trip or stumble, it causes the knee to default to its most stable setting, preventing the fall. This is what allows users to walk down stairs and slopes step over step with absolute security.

This file type includes high resolution graphics and schematics when applicable.

More Modes

This file type includes high resolution graphics and schematics when applicable.

That’s a basic description of the primary mode of operation. For special situations, there is a second mode that can be programmed for each user by C-Leg practitioners. This second mode can be used to create a free-swinging leg for bicycle riding, for instance, or higher resistance for standing, such as a surgeon might require during long procedures.

While afoot, users can switch between modes in two ways. There is a hand-held remote control that can toggle the switch. But for more intuitive operation, the user can bounce on the toe three times. For users who have grown more comfortable with the C-Leg, the remote control lets allows them to make incremental adjustments to swing-phase dynamics.

Finally, there is also a “standing” mode, something no other artificial limb offers. This mode sets the knee at any flexion angle between 7 and 70 degrees to allow the user to shift weight so the prosthesis can relax their sound limb. To engage the standing mode, the user selects this option on the remote control, flexes the knee, and then straightens it slightly to the desired flexion angle.

Alternate Versions

There are actually two versions of the C-Leg knee, the Standard and the Compact. The Standard version is intended for those users who can utilize second mode for varied activities; those with higher activity levels who can take advantage of the microprocessor-controlled swing-phase features; those who could improve their gait when using extension damping; and those who would benefit from the standing mode—in other words, the whole gamut of features described above.

The Compact, on the other hand, is best suited for those who need optimum stance-phase stability, but who, because of a more limited activity level, would not benefit from highly variable swing-phase adjustments and who do not frequently engage in activities for which they require the second mode.

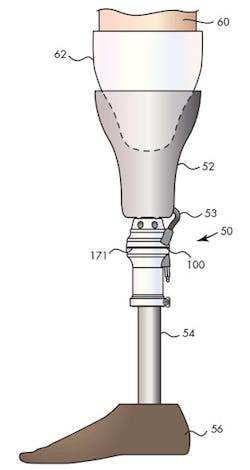

Making It Fit

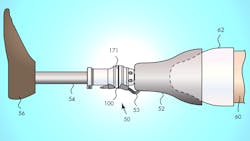

The C-Leg is more than its microprocessor-controlled knee joint. It’s also engineered for comfortable, reliable fit, and long periods of wear.(Fig. 2). According to an Otto Bock patent, (US8568489), C-Legs provide a socket for the limb, with a plastic liner. A battery-powered pump creates a vacuum that forces the residuum of the user’s leg down against a squishy, fluid-filled, donut-shaped, soft plastic piece. When a vacuum is applied, fluid is forced out of the donut through a two-way valve and into a flexible reservoir.

The valve arrangement allows dynamic cushioning between the residuum of the leg and the socket as the user walks without breaking the suction that secures the prosthesis to the user. The vacuum pump is also controlled by the microprocessor that controls the swing and stance modes of the knee joint.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Don Tuite

Don Tuite (retired) writes about Analog and Power issues for Electronic Design’s magazine and website. He has a BSEE and an M.S in Technical Communication, and has worked for companies in aerospace, broadcasting, test equipment, semiconductors, publishing, and media relations, focusing on developing insights that link technology, business, and communications. Don is also a ham radio operator (NR7X), private pilot, and motorcycle rider, and he’s not half bad on the 5-string banjo.