Truly Weird Science: Energy Harvesting from Ambient Humidity and “Wires”

The potential sources of energy that can be harvested for free—or close to it—almost defy imagination. While some, such as wind, fluid flow, and solar, are somewhat obvious, others are not. Consider this: the non-intuitive source developed by a university research team based on ambient humidity (even in dry climates) that uses their special bacteriologic “wires” having unique characteristics. The result reinforces the “aura” surrounding some harvesting implementations: sometimes you can get something for nothing (or close to it), and sometimes, yes, there is a “free” lunch.

What makes this humidity-driven harvesting arrangement work are the electrically conductive protein nanowires produced by the microbe Geobacter. It has been exploited by a team at the University of Massachusetts (Amherst) to develop what they dub the “Air-gen” (short for “air-powered generator”). It connects electrodes to the protein nanowires in such a way that electrical current is generated from the water vapor naturally present in the atmosphere—neither sunlight nor wind are required.

The team acknowledges that this isn’t the first moisture-based energy-harvesting technology. However, those can produce only intermittent, brief bursts of power in the ambient environment (typically under a minute) due to the absence of sustained conversion mechanism. In contrast, their thin-film devices are made from nanometer-scale protein wires harvested from the microbe Geobacter sulfurreducens and can generate continuous electric power in the ambient environment.

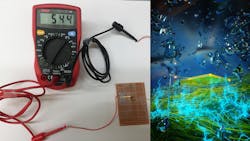

The devices produce a sustained voltage of around 0.5 V across a 7-µm-thick film, with a current density of approximately 17 µA/cm2. The devices can be connected to scale up the voltage and current to power small devices (Fig. 1).

The underlying source is a self-maintained moisture gradient that forms within the film when the film is exposed to the humidity that’s naturally present in air (Fig. 2). The bottom of the film rests on an electrode, while a smaller electrode that covers only part of the nanowire film sits on top, so that the film adsorbs water vapor from the atmosphere. A combination of the electrical conductivity and surface chemistry of the protein nanowires, coupled with the fine pores between the nanowires within the film, establishes the conditions that generate an electrical current between the two electrodes.

The background for this interdisciplinary development is also interesting and circuitous, and perhaps fairly representative of the way many innovations occur. Microbiology professor Derek Lovley discovered the Geobacter microbe in the mud of the Potomac River more than 30 years ago, and later uncovered its ability to produce electrically conductive protein nanowires.

Electrical engineering professor Jun Yao had developed electronic devices with silicon nanowires at Harvard University before coming to UMass, where they worked together to see if useful electronic devices could be made with the protein nanowires harvested from Geobacter. Xiaomeng Liu, a Ph.D. student in Yao’s lab, was developing sensor devices when he noticed something unexpected, noting “I saw that when the nanowires were contacted with electrodes in a specific way the devices generated a current. I found that exposure to atmospheric humidity was essential and that protein nanowires adsorbed water, producing a voltage gradient across the device.”

The research was supported in part from a seed fund through the Office of Technology Commercialization and Ventures at UMass Amherst and research development funds from the UMass College of Natural Sciences. The work is described in detail (including the microbiologic principles) in their Nature paper “Power generation from ambient humidity using protein nanowires,” along with additional Supplementary information.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.