11 Myths About Power Density

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- Setting the record straight about power-density measurements.

- Power-density aspects of Li-ion batteries.

- What's the low-down on wireless power transfer, wind-power density, EV onboard chargers, and dc microgrids?

Power density is an often confusing and misunderstood concept. Here are 11 myths about power density, followed by the facts that debunk them.

1. A large battery has higher power density than a small capacitor.

False: A small capacitor might have the same power output as a large battery, but the small physical size of the capacitor makes it a higher-power-density device.

For example, a tiny capacitor may have the same power output as a large battery. However, because the capacitor is so much smaller in volume, it has a higher power density.

Why?: Batteries are able to store more energy, but capacitors can give off energy more quickly! Since high power density systems release their energy quickly, they can recharge quickly as well.

2. Mounting a power transistor to a heatsink on one side of its package for cooling will lead to an optimum improvement in power density.

False: If designers choose a power transistor that can also have a good thermal connection on both sides of its package, then this will further improve the overall system power density and reduce system cost.

Why?: First determine the right size for the heat-spreading copper pad and how many vias will be needed under the thermal pad on the printed circuit board (PCB). If a heatsink can be attached to the other side of the power transistor package, that would optimize cooling and lead to better power density.

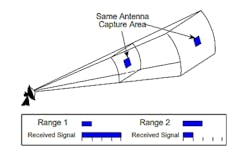

3. Antenna power density in an isotropic antenna is straightforward and simple to calculate.

False: An isotropic antenna/radiator is omnidirectional with uniform power density in all directions. With radar, we now need to determine power density at various distances from the transmitter. We must image the surface area of a sphere (4πR2) at a particular distance R (the range from the antenna which is the radius of the sphere). Since the surface area of a sphere will increase by the square of its radius, the power density (PD), in W/m2, will decrease by the square of the radius.

Therefore, power density from the isotropic antenna is:

PD = Pt (transmitter power)/4πR2

Why?: Power density from an isotropic antenna is complicated enough, but designers also may want to look at radar, which is a subset of isotropic antennas. With radar, we will want to look at power density at some distant point, from an isotropic antenna, multiplied by the antenna gain (Gt) (Fig. 1).

Radar power density PD = PtGt /4πR2.

4. Power-density measurements are based on either area or volume of the power design. Looking at the volume of a power design, power density is the output power processed (VO × IO) divided by the area formed by the rectangular area of the PCB (W) and multiplied by the average height of all the components on that board. Power density in terms of area would simply be the power processed (VO × IO) by the rectangular area of the board (L × W).

False: Looking at the volume of a power design, power density is the output power processed (VO × IO) divided by the area formed by the rectangular area of the PCB (W) and multiplied by the height of the highest component on that board.

5. Lighting power density (LPD) is measured in watts per square foot, or energy consumed divided by the size of a space. Wattage is a measure of energy consumed per unit time (joules/second); LPD uses this fact in their calculations.

False: LPD actually ignores this fact—it doesn’t have a time component. LPD is an inexact measure today since it doesn’t use wattage.

6. Lithium-ion batteries have very high power density.

False: Lithium-ion batteries actually have a relatively low power density of less than 1 kW/kg, typically 0.15 to 0.2/kg. Supercapacitors offer 15 kW/kg. There’s even a newer carbon-ion cell technology that has 1.5 kW/kg.

7. Wind-power density estimation, for electricity generation based on wind-flow data history in a particular region, is not accurate enough to determine the size and height of wind turbines to be used in that region.

False: Gathering many years of wind data, at selected region altitudes of some 10 or so meters above surface ground stations, will allow for fairly accurate examination of the energy potential of those specific locations. Such studies, using the Weibull characteristics, determine the optimal energy size and height of wind turbines needed for maximum air energy conversion into electricity.

8. Wireless power transfer (WPT) can’t increase its power transfer beyond present standard design architectures.

False: A proven technique of stacking receiver coils actually exists for wireless megahertz power-transfer systems. Multilayer coils are used to improve the equivalent inductance and Q factor of the receiver coil. Next, a corresponding compensation method can be used for the stacked, coil-based power receiver to achieve cross-coupling compensation and full resonance under the varying coupling and load conditions.

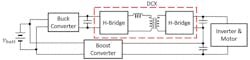

9. Electric vehicles (EVs), with separate high-power on-board chargers, provide comfort to the driver and passengers with increased range capability. At present, this is the best way to accelerate adoption of EVs.

False: The best way to accelerate adoption of EVs is to achieve lower weight and increased efficiency, employing a high-power, on-board EV charger into the drive chain. A composite boost dc-dc converter is positioned in the drive train, between the EV battery and the motor drive. This converter consists of multiple power modules: a buck module, a boost module, and a dc transformer (DCX) module (Fig. 2).

This design concept will enable efficiency and power-density optimization of the overall converter via a control strategy that maximizes the amount of direct power processed by the converter across a wide range of operating conditions. These factors enable the composite boost converter to have a much more improved efficiency and power density than a traditional boost-converter architecture.

10. Energy-storage system designs are best served with lithium-ion batteries.

False: Li-ion batteries have a high energy density of up to 250 Wh/kg with a low power density of less than 1 kW/kg. However, these batteries exhibit high flammability; their performance quickly fades over time; they’re quite high cost as compared to amount of energy stored; and can be very unsafe if overcharging occurs.

Supercapacitors are somewhat better for energy storage. They can provide energy far faster than batteries and have far longer life than Li-ion batteries, but they’re also flammable. On the other hand, carbon-ion (C-ion) cells, which employ nano-carbons and ionic electrolytes, allow for safe operation at higher voltages with no fire risk. C-ion cells have high longevity and high power-density capabilities.

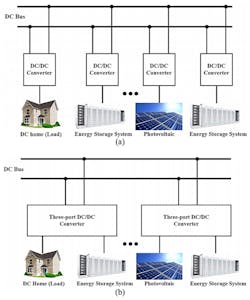

11. Due to the absence of ac resistance in the transmission line and fewer power-conversion stages, dc microgrids offer high efficiency. These microgrids have different energy sources connected, which highly rely on the weather conditions. Energy-storage systems (ESS) are needed to help the unstable power supply due to these irregular weather conditions. A conventional two-port dc-dc converter architecture connects one dc unit to one dc-dc converter with the grid; communication is needed between power converters. This is the optimum architecture regarding system size.

False: A dc microgrid with three-port dc-dc converters can interconnect two dc units with one converter to the grid with only a small number of components and employ just a single power-conversion stage (Fig. 3). The system will be smaller and simpler with less components, leading to higher power density and lower cost. Communication needed between power converters in a two-port dc-dc converter architecture can be removed.

Conclusion

Power density, a measure of how much power can be processed in a given space or area, is a necessary aspect for modern power supplies because efficiency is paramount—power density and efficiency are closely coupled. Power density enables miniaturization that fosters new applications and new markets. Economic advantages also come from better power density.

Still, power density isn’t well understood by many designers and should not be confused with energy density.

References

Electronic Warfare and Radar Systems Engineering Handbook - Power Density - RF Cafe.

A High Power Density Drivetrain-Integrated Electric Vehicle Charger, Usama Anwar, Hyeokjin Kim, Hua Chen, Robert Erickson, Dragan Maksimovic and Khurram K. Afridi.

High Power Density Bidirectional Three-Port DC-DC Converter for Battery Applications in DC Microgrids, Juyoung Sim, Junyoung Lee, Hyunjun Choi and Jee-Hoon Jung