Unique Applications that Demand High Power Density

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- How to achieve high power density in an offline LED driver.

- The need for high power density and high energy density in hybrid ESS.

- Power density needs in ESS cell balancing.

- Hybrid embedded power supplies for EVs.

In this second decade of the 21st Century, power density has become a very important, universal figure of merit (FOM) for power supplies and power-system architectures. An array of advances and new methods have arrived to help designers to achieve high power density, including 3D power packaging, innovative control methods, improved gate drivers and wide-bandgap power transistors, new converter topologies, and higher circuit-integration techniques, just to name a few.

Here we’ll present several unique design methods to achieve high power density in four major design architectures. These design examples will help fuel the creative juices of power designers in this new millennium.

Offline LED Driver

In this design architecture, we not only get high power density, but also longer lifetime for the LED drivers to keep pace with the exceptional long life of LED lights. It’s possible to achieve this long lifetime for LED drivers thanks to the elimination of standard electrolytic capacitors for twice-line-frequency energy buffers.1 Electrolytic capacitors typically have shorter lifetimes than ceramic capacitors (manufacturers of electrolytic capacitors specify the design lifetime at the maximum rated ambient temperature, usually 105°C). This design lifetime can vary from as little as 1,000 hours to 10,000 hours or more. The longer the design lifetime, the longer the component will last in a given application at ambient temperature.

Enter the ceramic capacitor. The capacitance offered by ceramic capacitors diminishes with an increase in dc bias voltage. Utilizing them at a lower dc bias voltage than the dc bus voltage ensures that they offer higher energy density. Ceramic capacitors can handle more ripple current and heat better than an electrolytic variety. The lifetime of electrolytes in an electrolytic capacitor is severely degraded by heat.

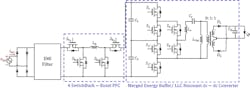

Figure 1 shows a proposed high-power-density LED driver with no electrolytic capacitors.

The converter achieves the best efficiency at low switching frequencies and at intermediate values for the power-factor-correction (PFC) inductor, Lb . In terms of passive volume, the volume of an input EMI filter is included since its design depends on the PFC inductor current’s ripple and switching frequency. Due to this optimization, a switching frequency of 500 kHz and a three-stage input EMI filter is chosen for the PFC stage.

The four-switch, buck-boost PFC stage chosen provides design flexibility for the selection of the intermediate bus voltage. That voltage, in this design example, is selected at 100 V to enable the use of the highest-energy-density, commercially available ceramic capacitors for energy buffering, which minimizes the passive volume/size of the buffer.

The front-end, four-switch, buck-boost converter-based PFC stage reaches a peak efficiency of 97%. The second-stage LLC resonant converter reaches a peak efficiency of 93%. The prototype has a box volume of 3 in.3 and reaches a power density of 50 W/in.3 This design significantly improves power density.

Hybrid Energy-Storage Systems

Designers have proposed a new type of hybrid energy-storage system (ESS) that has both high power density and high energy density, leading to reduced investment and operational costs of the ESS, with broad application potential.2

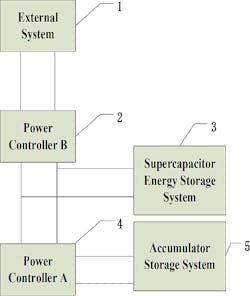

This system organically integrates high-power-density supercapacitors and high-energy-density batteries, leading to energy-storage characteristics of high power density and high energy density through complementary advantages. This system greatly improves the overall performance of the ESS as well as reduces its investment cost while meeting the power/energy regulation requirements of the external system (Fig. 2).

The energy-storage element uses the battery. The battery is connected to the low-voltage side of power controller A; the high-voltage side of power controller A is connected with power controller B after connecting with the supercapacitor storage system. The power controller A monitors the terminal voltage of the supercapacitor connected to its high-voltage side in real-time. This determines its charged state, and then controls the battery to carry out power stimulation, which will maintain the supercapacitor at a reasonably charged state. Power controller B is connected to the external system to control the power exchange between the hybrid ESS and the external system.

High power density along with high energy density is realized in this design architecture.

ESS Cell-Balancing Design

We need to lower greenhouse gas emissions to maintain healthy, breathable air on Earth. Renewable-energy sources and vehicle electrification play a key part in achieving this goal. Electric grids are deploying grid-tied energy-storage systems that will balance energy production and consumption demand. It also will reduce infrastructure upgrade costs for electrical grids.

The deployment of an active cell-balancing design, for a new kind of energy-storage cell, known as the carbon-ion (C-ion) cell, will enable high longevity and high power density.3 Power density for the C-ion technology is 1,500 W/kg as opposed to traditional lithium-ion at 150 W/kg and supercapacitors at 1,500 W/kg. High power density enables C-ion technologies to safely charge and discharge within minutes with the benefit of 100,000 cycles during their lifetime. These devices also have far higher energy density than supercapacitors.

Voltage imbalances will occur in series-connected ESS while charging and discharging due to C-ion cell parameters that are slightly different from cell-to-cell due to the manufacturing process. These packs are series-connected, so the same current flows through all cells of varying capacitance, equivalent series resistance (ESR), and leakage current.

During a constant current charge, current integration increases the C-ion pack voltage proportionally with respect to the capacitance. If maintaining a charge for an extended period, the leakage current will vary in these cells and cause an imbalance between the packs in the series. This may cause a cell overvoltage condition and decreased ESS accessible energy while under standard use.

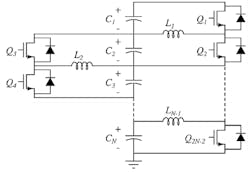

To keep the voltage consistent in the series-connected C-ion system, designers have developed a series of interleaved, connected, cascading half-bridge circuits (Fig. 3).

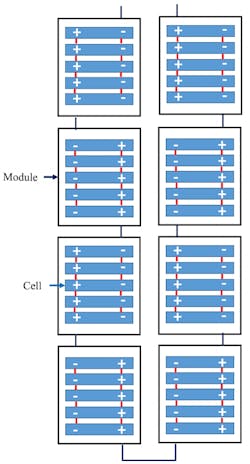

Finally, this cell architecture can consist of assembled module packs in series, made up of five cells in parallel (Fig. 4).

The cells in this architecture, made up of carbon-ion, exhibit long lifetimes and high power. Electric-vehicle superchargers and grid-stabilization systems are prime candidates for this design. And it now adds improved power density.

Hybrid Embedded Power Supply For EV Apps

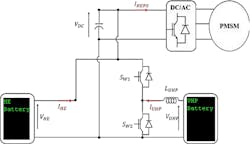

In the new era of electric-vehicle (EV) applications such as those with an embedded power supply, high power along with high energy density, a long lifetime, lightweight design, and modest cost are a must.4 To achieve these targets, the system power design needs to deal with the hybridization of batteries connected to the dc bus via an active arrangement using one dc-dc power converter on the side of the auxiliary battery. The main source of this hybrid embedded power supply (HEPS) is a high-energy-density lithium-ion battery; the second is an ultra-high-power (UHP) lithium-ion battery (Fig. 5).

UHP batteries have small internal resistance, high specific power, and low self-discharge rate, which compete with supercapacitors in terms of specific power with the benefit of higher energy density. The features of this technology are closer to supercapacitors than other regular batteries, thanks to their ability to discharge at very high currents. The main goal of using UHP batteries, in the HEPS, is to supply enough power and energy to meet EV requirements.

The hybrid particle swarm optimization Nelder-Mead algorithm5 (PSO-NM) was used to optimize the system. This method helps find the best tradeoffs among optimal performances under the many constraints of the electric vehicle.

Combining a UHP battery with another HE battery, in an EV, improves system performance in terms of weight, RMS power stress applied to battery, and battery quantity of charge. However, it also significantly increases the system volume and cost.

An analysis of the best possible configurations of the embedded power supply has shown that better sizing preferences can be obtained by operating the UHP battery as an energy source instead of a pure power source. Energy is the ability to create a change; a battery will hold a particular amount of energy. Power is how fast energy is used or transmitted—it’s the amount of energy divided by the time it took to use the energy in watts (one joule/second).

Again, high power density, as well as high energy density, is achieved in this design architecture.

Summary

The four high-power-density architectures in this article show the emergence of power density as a significant yardstick for modern power supplies. Power-density designs enable significant, measurable cost savings as well as size, weight, and power savings in the final product. Power density is a much-valued metric in power supplies in today’s market and will continue to be a need in the foreseeable future.

Read more from the Power Management Series: Delving Into Power Density

References

1. “A High-Power-Density Electrolytic-Free Offline LED Driver Utilizing a Merged Energy Buffer Architecture,” Mausamjeet Khatua, Danish Shahzad, Saad Pervaiz and Khurram K. Afridi.

2. “Research on Hybrid Energy Storage System with High Power Density and High Energy Density,” iSPEC 2020, IEEE Sustainable Power and Energy Conference, Ghengdu, China, November 2020.

3. “Evaluation of a cell balancing circuit for a new type of high-power density energy storage system,” 2020 IEEE Green Energy and Smart Systems Conference (IGESSC).

4. “Hybrid Embedded Power Supply Combining High-Energy Density and Ultra-High Power Lithium-ion Batteries For Electric Vehicle Applications,” IEEE 2020.

5. “A Hybrid Particle Swarm Optimization Algorithm for Combinatorial Optimization Problems,” IEEE 2010.