GaN’s Power Density Carries Unlimited Design Potential

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- How GaN helps boost efficiency in data centers.

- What is the LLC resonant converter?

- Using the AC-DC-AC converter for UPSs with no transformer.

Gallium-nitride (GaN) FETs have inherently superior performance versus traditional silicon FETs. This advantage in performance enables design engineers to push the envelope in power designs and reach new levels of power density and efficiency. Applications range from ac-dc power supplies to multi-kilowatt, three-phase converters.

GaN Power Density in the Data Center

GaN technology enables energy-efficient power supplies for data-center servers. GaN power transistors reduce the weight, size, and cost of data-center power designs while also reducing energy consumption. GaN’s high-speed switching enables market trends like ultra-thin power supplies, motor-drive integrated robotics, and the ability to achieve greater than 200% more power density in next-generation data centers.

High-performance server and telecom applications need high-efficiency and high-power-density isolated dc-dc converters. As such, LLC resonant converters look like an optimum choice for this use case. This converter architecture has a zero-voltage-switching (ZVS) capability from zero to full load, plus a low turn-off current for primary-side switches. In the case of switching frequencies lower than resonant frequency, synchronous-rectifier (SR) devices are turned off with zero-current switching (ZCS).

Integrating the driver and protection circuitry with GaN FETs will provide excellent power density for space-limited data center boards.

GaN in Power Modules for the Data Center

In today’s 48-V-based input power architecture in the data center, LLC resonant converters provide a good power architecture for power modules. Data-center board footprint needs to be reduced, especially for power supplies. Power density is critical in this case, and that where GaN power devices step in, since they offer greatly improved power density over silicon.

The 48-V to 12-V dc-dc converter using GaN power devices offers higher frequency, better efficiencies, and excellent power density. The server industry saw the benefits of the 48-V power distribution, which are:

- A much easier distribution and delivery for higher power.

- An improved solution to power the CPU is to use a non-isolated/regulated converter to convert from 48 V to 1 V or less for the data-center processors. The best way to achieve highest efficiency is a two-stage design with 48 V to 12 V and then 12 V to 1 V or less (or 5 V to 1 V or less), which powers the central processing unit (CPU).

Why is an LLC Resonant Converter Best in this Design to Achieve Optimum Power Density?

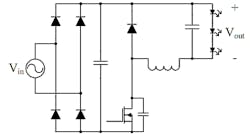

A quasi-resonant floating buck converter is an ideal topology to use in this application (Fig. 1). It reduces switching losses by valley switching the FET in a resonant manner1 without any additional components.

This design has a transformer, a full- or half-bridge on the primary side. Synchronous rectification takes place on the secondary side. It’s a relatively simple architecture and has very high power density. The topology features multi-phase operation for higher output currents. Using the optimum transformer along with high-efficiency FETs leads to 98% efficiency, even up to 1 kW.

Changing the transformer ratio makes it easily adaptable for higher output voltages. This LLC solution is best in size and efficiency for higher voltage above 600 W with 48 V to 12 V or 48 V to 5 V, making it perfect for a power module (smaller than a 1/8 brick). GaN FETs in this LLC design architecture enable a smaller, more efficient converter architecture with lower losses and 1-MHz switching frequency, which leads to smaller magnetics. Power density exceeds 1,500 W/in.3 without the need of a heatsink.

GaN FETs also are great fits in soft-switching LLC resonant converters.

GaN-Powered LED Driver

LEDs are revolutionizing the lighting industry. They’re efficient, last far longer than incandescent or fluorescent lights, and are dimmable. LEDs need dc power, but since traditional lighting has ac power, a rectifier needs to convert ac to dc power. Power converters for LED lighting typically need to be in a small form factor and many times must handle relatively high temperatures in enclosures.

Enter GaN power transistors in a switched-mode power supply at high switching frequency, which leads to smaller magnetics. Soft switching is a bonus for these kinds of designs. One design idea is to use a 600-V, 1-Ω GaN FET for the power transistor. Since GaN is able to switch at very high megahertz rates, the passive filter component sizes will be much smaller, significantly enhancing power density.

The design can be a 20-W power converter, which is measured to have a size reduction of 1.87X the power stage when compared to an existing commercial product while achieving an efficiency of 91.2%, an input current total harmonic distortion (THD) of 15.9%, and power factor of 0.976.2

GaN-Based AC-DC-AC Converter for UPS with No Transformer

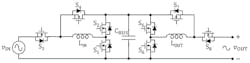

This GaN AC-DC-AC converter power design needs no transformer and may be used in an uninterruptible power supply (UPS). The design has a common neutral in between the input and output ac ports.

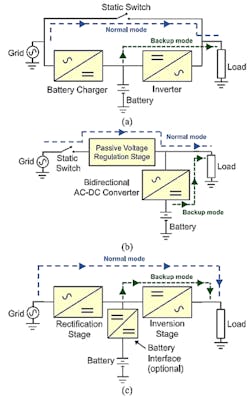

In each topology shown in Figure 2, the presence of a transformer rated for peak ac power limits their efficiency (typically less than 90%) and negatively affects power density. All three examples manifest distinct characteristics in terms of their normal-to-backup mode changeover time (also known as transfer time), as well as their ability to reject voltage disturbances at the input voltage.

In an offline UPS (Fig. 2a), there will be a high changeover time. It provides the least protection against input voltage disturbances while in normal operation, which is due to the inverter operating only during backup mode. This architecture is best for household usage in which the input voltage will see only short-lived disturbances without affecting the load. In this case, the grid voltage typically is high quality and normally available.

In large industrial areas, where the power grid may be prone to fairly frequent and high power, quality is important. The line-interactive UPS (Fig. 2b) will be better than an offline UPS.

And finally, in areas where uninterrupted input voltage is paramount for safety and operation of critical loads, the online UPS is best suited (Fig. 2c). The best topology choice for this UPS architecture is the proposed online UPS with a common neutral between the input and the output (Fig. 3). It has a front-end power-factor-correction (PFC) rectification stage that’s followed by a voltage-mode inversion stage with a single energy buffering capacitor (CBUS) connected across the intermediate dc-bus.

The online UPS design will deliver as much as 1-kVA power to the load with a PFC spanning from −0.5 to +0.5. It has the capability to operate with a 120 Vrms at 50/60-Hz line frequency along with an ac output voltage of 120 Vrms at 60 Hz.

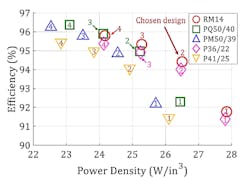

Now with a reasonable tradeoff between power density and efficiency, a design option is chosen using two paralleled GaN transistors. Figure 4 shows designs using a lower number of paralleled transistors, which offers better power density. That’s because the reduced board area, occupied by transistors and the associated gate drive circuitry, will result in lower efficiencies as the designs are conduction-loss dominated.

Thus, to attain a reasonable tradeoff between power density and efficiency, a design option with two paralleled GaN transistors was chosen. A GaN-based, electrolytic-free, 1-kVA prototype online UPS was designed, built, and tested. The prototype UPS achieved a peak efficiency of 95.2% and maintained a high efficiency of more than 92.3% across the entire output power range. The electrolytic-free prototype online UPS achieved a power density of 26.4 W/in3.

Summary

This article has presented just a selected few power design architectures using GaN power FETs. A plethora of examples for GaN power-density designs exist in the References, as well as online, which the reader may examine. New articles and application notes are being created almost daily regarding power density and GaN.

Read more articles in the Power Management Series: Delving Into Power Density

References

1. GaN in Practical Applications.

2. “High Efficiency and Power Density GaN-Based LED Driver,” Texas Instruments

3. “GaN-Based High-Power-Density AC–DC–AC Converter for Single-Phase Transformerless Online Uninterruptible Power Supply,” IEEE Transactions on Power Electronics, Vol. 36, No. 12, December 2021.

“The Quest for GaN Power Density Continues,” Microwave Product Digest (mpdigest.com).

“TI brings the power of GaN technology to Delta Electronics' energy-efficient server power supplies for data centers”, Yahoo Finance.

“Designing a 1kW GaN PFC Stage with over 99% Efficiency and 155W/in3 Power Density,” IEEE 2017.

“A High-efficiency, High-power-density, 1MHz LLC Converter with GaN Devices and Integrated Transformer,” IEEE 2018.

“A 6-level Flying Capacitor Multi-level Converter for Single Phase Buck-type Power Factor Correction,” IEEE 2019.

“A Monolithic E-Mode GaN, 15W 400V Offline Self-Supplied Hysteretic Buck Converter, with 95.6% Efficiency,” 2020 IEEE International Solid-State Circuits Conference, IEEE 2020.