Power-Density Techniques Using Integrated WBG Devices

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- How WGB devices surpass their silicon cousins in terms of speed, size, etc.

- What's an IMD and what types of motors are used in these drives?

- A look at a full-bridge inverter design.

- The pervasiveness of WBG technology in electric transportation.

Wide-bandgap (WBG) power transistors, especially those with 10 kV and above voltage capability, will enhance medium- and high-voltage systems. They will deliver unique capabilities to the design in ways that silicon could never achieve.

However, such devices aren’t always easy drop-in replacements for silicon devices. Larger, more complex systems must be redesigned to integrate them.

In this article, we’ll demonstrate some power-density approaches with the integration of WBG solutions into power designs. WBG integration will open new doors to a plethora of design architecture improvements in areas that we’ve never seen.

Motor-Drive Integration

WBG devices versus silicon will lead to higher speeds (meaning smaller magnetics), smaller physical sizes (especially for power magnetics), and higher reliability. Weight, volume, and costs during lifecycle will be slashed in power designs. Designers now can greatly improve motor-drive designs by integrating an electric motor and drive by using WBG power devices.

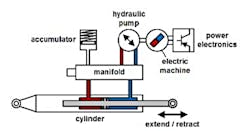

High-Performance Electro-Hydrostatic Actuators (EHAs)

An integrated motor drive (IMD) can improve power density with a 10% to 20% lower volume. A bonus is that less volume will typically reduce system costs for installation and manufacturing by 30% to 40%.

Designers will no longer need such things as shielded cables, separate inverter enclosure, centralized controller cabinet, or high-voltage and high-current bus bars, lowering the final cost of the design. It thus paves the way for the electrification of actuators in key areas such as aerospace, robotics, automobiles, manufacturing, and off-road vehicles (Fig. 1).1

Decentralized and electrified actuation systems also will improve electromagnetic interference (EMI) as well as electromagnetic compatibility (EMC). This is achieved by directly connecting the motor drive to the motor, eschewing the need for additional cables.

Modularizing motor drives, and employing WBG power devices, will improve performance of the IMD regarding power density, efficiency, high-temperature operating capability, as well as fault tolerance.

Types of Motors in an IMD

Designers can choose among four different kinds of motors for an IMD:

- Induction machine (IM)

- Surface-permanent-magnet (SPM) motors have the magnets affixed to the exterior of the rotor surface. Because of this mechanical mounting, their mechanical strength is weaker than that of IPM motors.

- Interior permanent magnet (IPM)

- Switched reluctance motor (SRM)

The growing demands of high power density as well as high-temperature operation in an EHA will be met with the aforementioned emerging power electronics and motor design technologies.

High-Power-Density Inverter Design

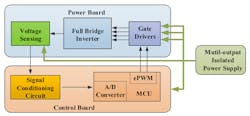

A full-bridge inverter design, based on gallium-nitride (GaN) power transistors, will enhance the performance of a power inverter design.2 The carrier phase-shifted sinusoidal pulse-width-modulation (SPWM) scheme is adopted to double the equivalent frequency of magnetic components.

Designers must carefully design the gate-drive circuits because of the sensitivity to the parasitic parameters of the gate-driving loops. Using a bottom-cooling thermal design along with common-mode noise reduction will significantly improve the inverter’s performance.

The design example is a 500-W single-phase full-bridge inverter. Power density is calculated as 60 W/in.3, with a peak efficiency of 96.2% at full load (Fig. 2).

SiC power-loss estimation is performed utilizing a fully integrated electromagnetic-circuit simulation.

WBG Power Density in Transportation

Here’s another great example of WBG power being integrated into electric drives in road motor vehicles and aircraft.

Due to Earth’s growing environmental problems, the reduction of fossil-fuel consumption in worldwide transportation has become a major concern. One possible way to help achieve the goal of cleaner air in motor vehicles is to use WBG power devices, which are able to push switching frequencies to higher levels and dramatically raise output power levels of transportation electrical systems.5

Such devices achieve that capability thanks to higher blocking voltages, smaller parasitics, and higher operating frequencies. WBG benefits are reduced size of power designs, lower costs, and higher reliability.

Power converters deployed in transportation applications are typically powered by batteries that can support multiple loads. Transportation vehicles experience considerable effects from load changes, crank, or jump-start, creating transients. To minimize the impact of these transients, power converters must be able to operate under a wide input-voltage range of high ambient temperatures and low air densities.

Enter Universal Serial Bus (USB) Power Delivery (PD), which will aid in extending the delivered power. To achieve the specifications, power converters must be designed to provide a wide output-voltage range—a major challenge for the converter designer.

The vehicle charger is typically fed by an ac voltage greater than 100 V. That voltage is then stepped down to 5 to 20 V. That high step-down ratio will further increase the converter losses.

To help overcome wide input-voltage and high-temperature challenges, a dual-output, PCB-embedded transformer based on an active-clamp-flyback (ACF) gate-drive power supply was proposed for automotive applications. By embedding the PCB, this will effectively improve the power converter’s power density.

The final prototype achieved a power density of 53.2 W/in.3, a peak efficiency of 89.7%, a transformer input-output capacitance of 9.7 pF, and a wide input-voltage range of 9.9 to 28 V. Maximum operating temperature was 105°C while operating at a low-line (LL) voltage; with a high-line (HL) voltage, maximum operating temperature was 115°C.

Unfortunately, this design didn’t initially meet the design targets due to transformer material degradation. This was caused by mechanical stress that was induced in the process of integration. With some further analysis and correction factors, it was determined that an improved transformer design would have successfully achieved the targeted wide input-voltage range.

Summary

This article touched on the integrating of WBG devices into any transportation vehicle power design. It’s been shown that WBG power devices greatly improve power density in many kinds of applications, including power inverters, motor drives, electro-hydrostatic actuators, and road vehicle and aircraft transportation.

Of course, many more applications exist beyond those mentioned here, as well as more to come that will be “powered” by engineering creativity.

Read more articles in the Power Management Series: Delving Into Power Density

References

1. “A Review of Integrated Motor Drive and Wide-Bandgap Power Electronics for High-Performance Electro-Hydrostatic Actuators,” IEEE Transactions on Transportation Electrification, Vol. 4, No. 3, September 2018.

2. “A High Power Density Inverter Design Based on GaN Power Devices,” 2018 8th International Conference on Power and Energy Systems.

3. “Opportunities and challenges of integrated WBG power electronics development,” 2021.

4. “Estimation of Switching Transients and Power Losses of SiC-based Power MOSFET Inverter Using Electromagnetic-circuit Co-simulation during Six-step Commutation.”

5. “Integration Challenges In High Power Density Wide Bandgap Based Circuits for Transportation Applications,” Virginia Tech.

6. “Rugged WBG Devices and Advanced Electric Machines for High Power Density Automotive Electric Drives,” Oak Ridge National Laboratories.