When two competing technologies approach cost parity, the better performing technology will always win out in the market. This is an accepted truism throughout the embedded electronics and semiconductor technology ecosystems, albeit affected by myriad factors that dictate the timing of the inflection point.

For a wide range of applications spanning from cooking and lighting, to medical and automotive and beyond, parallel advances in solid-state RF energy systems and semiconductors are poised to transform huge segments of our commercial marketplace. At the system level, the inherent limitations of magnetrons as a heat and energy source have spurred considerable innovation in controlled, high-power RF generation and radiation techniques. At the semiconductor level, the performance limitations of LDMOS have fueled the ascension of GaN-on-silicon (GaN-on-Si) to the forefront of the RF semiconductor industry.

The parallel evolution of solid-state RF energy technology and GaN-on-Si sets a clear path forward for OEMs competing for leadership in the aforementioned commercial markets. As these technologies continue to advance, market awareness continues to grow, and the underlying economics come into favorable alignment, mainstream adoption of solid-state RF energy technology is approaching quickly on the horizon.

Beyond the Magnetron

The ability to generate and amplify RF signals using solid-state semiconductor devices is nothing new—this technology is the cornerstone of modern wireless communications. But solid-state RF energy has enormous potential beyond data transmission applications. It’s increasingly being used for the purposes of heat and energy generation, enabling greater efficiency and control than what’s possible with the conventional magnetron tubes that—among other things—have been powering the microwave ovens in our homes for the past 50 years.

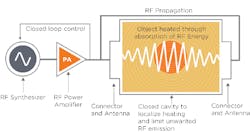

One of the major deficiencies of magnetron tube-based RF energy delivery is the inability to measure and adapt to energy that’s irradiated and reflected within the cavity where the energy is outputted. Magnetrons deliver open-loop, crudely-averaged energy output, whereas with multi-antenna, solid-state RF energy sources, forward and reflected power levels can be easily assessed and adapted to with closed-loop, precision control over the frequency, output power, phase and RF signal modulation (see figure). Solid-state RF transistors can also provide 10X longer lifespans than magnetrons, ensuring significantly higher reliability.

This block diagram illustrates solid-state-generated RF for local heating applications.

Massive Market Opportunities

The initial target applications for solid-state RF energy are many, and it’s likely that additional applications will emerge as the technology is further developed and commercialized. Here we’ll assess some of the identified markets where RF energy is primed for mainstream adoption in the coming years:

Solid-state Microwave Cooking

Today’s magnetron-based microwave ovens can’t adapt to energy that’s reflected from the food into the cavity as it cooks, and they typically depend on a rotating turntable at the base of the cavity as a means of averaging the heat distribution. This imprecise energy delivery often results in over-cooking and hot spots that lower the food’s nutritional value, and cold spots that negatively impact the dining experience.

By using multiple solid-state power amplifiers and antennas with closed-loop control between the RF amplifier and RF synthesizer to adjust for energy absorption and radiation, the energy can be directed with greater precision to exactly where it’s needed to ensure optimal temperature control.

Rather than rely on moisture sensors that measure humidity in the cooking cavity—an indirect mode of measurement that’s sometimes implemented in modern magnetron-based microwave ovens—solid-state microwave ovens measure the properties of the food itself while it cooks, and adapt accordingly to changing load conditions or the food cooking state. This promotes the retention of the nutrients, moisture, and flavors of the food.

The adoption of solid-state microwave ovens will begin in the industrial and commercial cooking markets, where the value provided by these systems will be well worth the modest increase in cost. Customers will gain significant advantages centric to system reliability, food-processing speed, and throughput. This technology will later migrate to consumer kitchens, and its value will evolve from that of a simple heating mechanism, to a device that’s capable of cost-effectively cooking healthier, multi-course meals with unprecedented efficiency.

Solid-State Plasma Lightning, aka Light-Emitting Plasma (LEP)

Plasma lighting is on a trajectory to supplant LEDs and high-intensity-discharge (HID) lighting across a host of applications where plasma lighting outperforms legacy light sources, having overcome the aforementioned reliability and lifespan limitations of earlier-generation magnetron-powered plasma lights. Typically, these are lighting applications where a high-quality light spectrum is required along with the need for lots of lumens from a small area.

One of plasma lighting’s major advantages over legacy light sources is its ability to emit a lot of light from a very small space. LEPs are characterized by extremely high lumen density—an LEP bulb the size of your fingertip can produce 10,000 lumens of light. In contrast, a similarly sized, high-density LED light would measure approximately 50 cm2.

LEPs are therefore well-suited for implementation in environments requiring brighter, higher-quality illumination than LEDs, HIDs, and halogen lights can deliver in a given form factor. Target applications include everything from vehicle headlights, hospital operating rooms, medical labs, and medical endoscopy devices and microscopes, to wide-area lighting environments like parking lots, warehouses, stadiums, airports, and shipping ports.

One application where plasma lighting has already made considerable inroads is horticulture. Grow-lighting environments, both big and small, are benefitting from LEPs’ unique ability to emit a continuous, full-spectrum light akin to natural sunlight—including ultraviolet UVA and UVB—without the need for a secondary phosphor conversion such as those used by LEDs.

Medical Care

Today’s RF-powered medical devices are designed to heat biological cells and tissue for medical treatments ranging from tumor ablation to bacteria sterilization, with minimal invasiveness. At the semiconductor level, devices that support high frequencies (shorter wavelengths) enhance the precision and control of the RF energy field to improve treatment accuracy, and devices that support high power output enable more power to be directed to the treatment site to dehydrate and/or burn away unwanted tissue.

Hyperthermia therapy is quickly emerging as another core target application for RF energy. Typically practiced in combination with other cancer treatments, physicians can use targeted RF energy to elevate the temperature of patients’ body tissue at the cancer site. The controlled heat (104°F to 108°F) stresses the cancer cells and reduces cancer-cell replication without impeding DNA replication among healthy cells. This technique holds great potential as a mainstream cancer treatment in the years ahead.

Looking to the future, one can envision that that RF medical devices will be used for warming blood and organs for transfusions and transplants. In the case of blood transfusions, RF energy can enable stored, chilled blood to be heated quickly and uniformly without creating harmful toxins, allowing rapid transfusions in emergency situations. Similarly, the ability to freeze and rapidly defrost donated organs without causing cellular damage could extend the organs’ shelf life and increase the odds of a successful donor/recipient match over longer timeframes and distances.

Automotive Ignition

Among the many target applications for RF energy, high-efficiency automotive ignition is perhaps the most exciting use case, given the enormous environmental impact of internal-combustion-powered vehicles. Today, spark plugs are used to deliver electric current from an ignition system to a vehicle’s combustion chamber, emitting an electric spark that ignites the compressed fuel/air mixture. This technology has served us well since its invention in the 1800s, but RF energy holds the promise to boost vehicle fuel efficiency by as much as 10% or more, while dramatically reducing carbon-dioxide emissions.

Leveraging RF energy in lieu of a spark plug, fuel in the combustion chamber can be ignited much more evenly than with conventional ignition systems. The continuous precision control afforded by RF energy enables more efficient fuel combustion, which in turn can improve fuel savings and reduce exhaust emissions.

Automakers grappling with increasingly stringent vehicle emissions standards are keenly interested in implementing RF plasma ignition systems—to everyone’s benefit. Aggregated globally, a 10% improvement in fuel efficiency for combustion-powered vehicles would represent a significant leap forward in carbon emissions control.

GaN-on-Si and LDMOS at a Crossroads

The accelerating innovation in RF energy systems runs parallel with the significant forward progress that GaN-on-Si has achieved relative to LDMOS in the semiconductor technology domain. The GaN-based devices targeted to underpin solid-state RF energy systems strike an optimal balance of performance, power efficiency, small size, and reliability, at an increasingly attractive cost structure at scaled volume production levels.

The performance benefits that GaN-on-Si delivers compared to LDMOS are well-understood. Where LDMOS compromises in power and frequency capability, GaN-on-Si demonstrates exceptional performance across both of these metrics, while offering several additional technical benefits. GaN delivers raw power density that’s considerably higher than LDMOS, with the ability to scale the device technology to high frequency.

GaN-on-Si is also distinguished by its high efficiency, providing up to 10 percentage points greater efficiency than LDMOS. Properly exploited, this efficiency delta can have a big impact at the system level in commercial RF energy applications. GaN’s high breakdown voltage is another noteworthy attribute for the ruggedness it contributes to the end design.

In terms of cost structure, when taking into account GaN-on-Si’s inherent power-density advantage and scalability to 8-in. substrates, GaN-on-Si is expected to yield RF devices that are more cost-effective at scaled volume production levels than LDMOS in absolute $/W before even considering the benefits at a system level. And the industry’s ability to support commercial-scale production of GaN-on-Si, maintain inventories, and accommodate surges in demand is now firmly established.

The parallel advances in the GaN technology roadmap and GaN supply chain have enabled the manufacturing scale and cost structures necessary to allow GaN-on-Si to accelerate its penetration into commercial applications powered by RF energy. For system designers and commercial OEMs weighing the price/performance merits of LDMOS-based devices for solid-state RF energy applications, GaN-on-Si is growing increasingly attractive and is poised to displace LDMOS in these applications going forward.

A Coordinated Effort

As with any emerging technology, the speed of RF energy technology’s commercial adoption hinges in large part on collaborative industry efforts to establish common standards. In the solid-state RF energy technology domain, the RF Energy Alliance (RFEA) is leading this initiative with support from industry leaders spanning RF semiconductor vendors, commercial appliance OEMs, and beyond.

This non-profit alliance aims to help standardize solid-state RF energy system components, modules and application interfaces. This will in turn will help to reduce system costs, minimize design complexity, ease application integration, and facilitate rapid market adoption. The RFEA works to reduce system design burdens and hosts frequent technical workshops to develop valuable industry guidelines, such as the RF Power Amplifier Roadmap for Residential Appliances.

Commercial OEMs have awakened to the huge market opportunity for GaN-based solid-state RF energy systems that remove most of the limitations of magnetron-based systems. But system designers are largely unfamiliar with this technology, and development challenges could slow their time to market. RF technology vendors are further helping the cause by providing development toolkits, such as MACOM’s RF Energy Toolkit, which help designers familiarize themselves with RF energy, and fine-tune RF energy output for their unique application requirements.

Conclusion

Magnetrons have outlived their usefulness for many applications, and spark plugs are long overdue for an upgrade. The performance and efficiency advantages of solid-state RF energy technology will manifest in commercially-released cooking systems within the next two years, and adoption will expand deeper into lighting, medical, and industrial heating and drying applications in short order. RF plasma automotive ignition systems are expected to reach the market as early as 2020.

The development and semiconductor costs associated with GaN-based solid-state RF energy technology will trend downward and ultimately intersect the price/performance trajectories of legacy technologies. When this happens, the ways in which we cook our food, illuminate our environments, treat our sick, and power our vehicles will be improved in profound ways, and massive commercial markets will be permanently transformed.

About the Author

Mark Murphy

Senior Director Marketing & Business Development for RF Power

Mark Murphy, Senior Director Marketing & Business Development for RF Power at MACOM – an RF Energy Alliance Member, graduated from Queens University Belfast in 1984 with a degree in Electrical and Electronic Engineering. He then spent 12 years at Analog Devices working on various IC designs using high frequency BiCMOS technology. This was followed by multiple management positions at Philips research, working on the development of high-performance mixed-signal analog technologies. Later he moved to NXP, where as head of marketing he grew the RF Power business into one of the top two RF Power suppliers worldwide for cellular networks. In 2013, he joined Dialog Semiconductor as General Manager of the emerging Bluetooth Smart business. In Nov. 2015, he joined MACOM as Senior Director of Marketing and Business Development for the RF Power business focusing on RF energy.