Download this article as a .PDF

According to IC Insights total semiconductor sales for Internet of Things (IoT) systems are expected to reach $31.1 billion in 2020, with the IoT semiconductor market for wearable systems expected to show a CAGR of 17.1%. This proliferation of devices is also creating future growth in the power management IC (PMIC) market.

Designers of IoT solutions are relying on power management solutions to efficiently handle the power needed to energize a wide range of IoT devices, as maintenance and battery replacement are not cost-effective approaches. There are many power management solutions currently in the market, and depending of their characteristics, one power management solution can work better for a specific application depending on power conversion and power control options.

PMICs can now reduce power consumption of the batteries prolonging the power in IoT devices while also minimizing PCB size. PMICs are now achieving lower quiescent currents that helps to increase battery life. Maxim Integrated’s new MAX20310, for instance, is a power management solution that operates with battery voltages down to 0.7V for use with single-cell zinc air, silver oxide, and alkaline batteries. This solution includes a dual-output, programmable, micro-IQ high-efficiency switching converter with a 0.5μA quiescent current. It focuses on wearable medical devices and fitness applications such as non-rechargeable medical patches, environmental and equipment monitoring, and discrete sensors for the Industrial Internet of Things (IIoT).

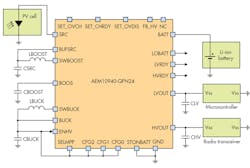

Some other PMICs come with integrated cold-start functionality that help to ensure the operation of the device even with low sources of ambient energy, like the ones use when harvesting energy from ambient sources (e.g., vibration, light, and RF). For example, a Belgian company called e-peas developed its AEM10940 PMIC (see figure) specifically to achieve more efficient energy harvesting for embedded electronics. Notable applications include very-low-power IoT wireless sensors, portable technology, domestic automation, and industrial control.

The AEM10940 harvests the available input power from 1 μW to 50 mW. It integrates an ultra-low-power boost converter to charge a storage element, such as a rechargeable battery, a capacitor, or a supercapacitor. It contains a boost converter that operates with input voltages in a range of 100 mV to 2.5 V. The cold-start functionality can start operating with an empty storage element at an input voltage as low as 380 mV and an input power of just 11 μW. As soon as a small amount of energy becomes available at the source pin, the Cold Start function raises VBOOST up to a voltage of 2 V.

As energy harvesting applications gain traction, the number of semiconductor companies offering evaluation kits or demo boards to explore the performance of PMICs functions built for energy harvesting applications continues to grow. For example, engineers can evaluate Cypress’ S6AE102A and S6AE103A PMICs, which can use solar energy to charge a super capacitor, along with a sensor board to analyze magnetic door sensor or ambient light sensor operation.

The CYALKIT-E04 kit can be used with Bluetooth Low Energy (BLE) wireless connectivity solutions from Cypress for IoT applications. The PMICs of this kit enable ultra-low power operation with quiescent currents of only 280nA and startup power of only 1.2μW.

IoT designers are now able to find more power management integrated circuit options for their designs in a wide range of applications spanning the automotive, consumer, and industrial markets. Future PMICs will aim to operate at lower voltages to provide a wide range of better reliable solutions to the harvesting energy market, which is rapidly growing as an acceptance of renewable energy resources.

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.