How Working Remotely is Spawning a Design Revolution

This article is part of the Professional Advancement Series: Annual Salary Survey

What you’ll learn:

- How COVID-19 is impacting design and development.

- Some of the solutions people are using to work remotely.

- How software-driven design will foment additional development.

The saying “every cloud has a silver lining” is very apt for the situation we’ve found ourselves in during this age of COVID-19. The forced isolation and need to separate has caused a great deal of hardship on every level and in every venue of society. However, the need to interact at both a social and business level forced us to investigate solutions such as telepresence and other collaborative tools to operate.

Holding meetings with people and sharing data with others online wasn’t a new concept a couple of years ago—that movement was already on its way to more widespread adoption. Companies were using these tools to do business before COVID-19, but they were mostly multinationals with far-flung principals and high-end freelancers who needed to be everywhere.

The pandemic created a “perfect storm” of need that significantly increased adoption of remote tools, causing additional development in a fledgling industry. The latest collaborative tools are not only useful for telepresence, they’re also fomenting a design revolution based on real-time design and manufacturing.

Impacting Work

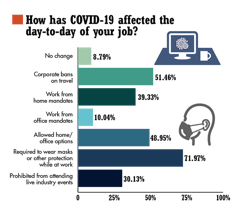

In our 2021 Salary Survey, we asked our engineering audience about how COVID-19 affected their day-to-day job (Fig. 1). The most prevalent business actions quoted included corporate bans on travel (51.46%), prohibitions on attending live industry events (30.13%), being allowed to work from a home office (48.95%), and even work-from-home mandates (39.33%). This pretty much forced everyone with the ability to create a home office to make one.

The tools required to perform work vary from company to company and industry to industry, but the common-need denominators include the ability to communicate with team members, schedule and manage event timelines, and share data and documents. These needs are often dealt with using separate software-based solutions, but a growing number of all-in-one collaboration suites are emerging.

This multifaceted need is driving even more functionality into currently available solutions. The collaborative-tool marketplace is a relatively new one, and like many software-based industries, far from mature. Many people now routinely perform a significant number of tasks using collaborative tools—a number that will grow in both number and depth as the tools continue to mature.

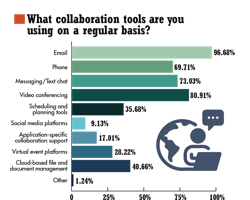

When we asked our engineering audience about the collaboration tools they currently use (Fig. 2), email led the list at 96.68%, beating out the telephone (69.71%) and texting (73.03%). Video conferencing has become a primary tool for both social interaction and business, coming in at number two with 80.91% of our respondents using it. This underscores the desire for the highest level of interactivity possible in interpersonal communications.

The next island of responses involved tools used to conduct business. The need to schedule and plan, to share files and documents, and to meet other people in a common industry is important for a business to operate. Tools for cloud-based file and document management (40.66%) narrowly edged scheduling and planning tools (35.68%), followed closely by virtual-event platforms (28.22%). This shows that many functions traditionally done face-to-face are being done virtually, successfully.

Cascading Benefits

Once people begin using a new tool, they also find new places and ways to use it as a solution for the needs around them. Most tools, regardless of type, offer peripheral benefits. Some of these are very apparent to the user and often are the primary purpose the solution was obtained. However, sometimes it takes a while for a tool’s full benefits to be appreciated.

For example, a design and development company may start using a collaborative planning tool to integrate the actions of a separated team, finding significant additional benefit in peripheral functionality. This could be something like the ability to create a bill of materials automatically, without the need of an additional engineer to monitor the process. That either reduces headcount or frees up a needed engineer for another aspect of product development.

This aspect directly addresses the shortage of engineers available to work on any given project, as one engineer can fill many boots with cloud-based development tools. In the survey, the most desired were RF (44.81%) and analog (41.54%) engineers. Sharing engineering resources isn’t just a software solution, because many of the latest benchtop hardware tools such as oscilloscopes can now be operated remotely. This enables an engineer to troubleshoot hardware from the other side of the globe, if there’s someone at the place of need who can place the probes for them.

Another significant benefit that comes from migrating your development process online is the ability to perform real-time design-while-build. Your team can utilize the same collaborative development tools they used to create a product, redesigning it on-the-fly to address manufacturing issues, functionality upgrades, or custom orders. The ability to react immediately to initiatives in a proactive manner can be a major force multiplier in a highly competitive marketplace.

Designing the Future

Not surprisingly, this growth in the market for collaborative tools of all kinds—societal and commercial—and the infrastructures needed for them is reflected in the design projects of our audience. When we asked them what best describes your current design project, 14.81% replied with communications systems and equipment, such as local-area/wide-area networking products, wireless, cellular, RF and microwave, Bluetooth, etc.

Another big area of interest was in industrial control systems and equipment (including robotics) at 9.88%, reflecting the impact of smart systems on manufacturing (Industry 4.0). This area of industry will eventually meld with the aforementioned collaborative development tools, further enabling real-time manufacturing oversight and management, and on-the-fly redesign and custom work.

This also is reflected in the answers to our question about the technologies having a major impact on their designs. Almost half of the responses (40.83%) said it was test equipment, which makes sense in light of the need to test, validate, and optimize these advanced interlaced technologies. Wireless networking came in second at 35.93%, followed by sensor integration at 32.12%, with power management a very important concern at 30.67%. It reflects the growth in the cloud-enabled IoT, the devices, and the infrastructure.

Looking Forward

The impact of COVID-19 may have accelerated the adoption of collaborative design tools, but the functionality they provide, and the cascading benefits offered, would have made the transition to their use inevitable. The latest generation of hardware and software solutions for engineering design and development is only beginning to mature, and the best in many ways is yet to come as these tools more deeply integrate into the engineering community.

Read more articles in the Professional Advancement Series: Annual Salary Survey

About the Author

Alix Paultre's Archive

Editor-at-Large

Also check out Alix's main author page for his latest articles.

An Army veteran, Alix Paultre was a signals intelligence soldier on the East/West German border in the early ‘80s, and eventually wound up helping launch and run a publication on consumer electronics for the US military stationed in Europe. Alix first began in this industry in 1998 at Electronic Products magazine, and since then has worked for a variety of publications in the embedded electronic engineering space. Alix currently lives in Wiesbaden, Germany.

Also check out hjis YouTube watch-collecting channel, Talking Timepieces.