Higher-Voltage Dual Op Amp Targets Automotive, Industrial Apps

The diverse world of op amps—that basic analog building block—never seems to rest. Despite the availability and need for middle-of-the-road, generic devices, there are always other new ones seeking to provide designers with an advantage and edge for one (or perhaps more) of the many niche segments: ultra-low power, low voltage, highest precision, or bandwidth. Recently, we’re seeing additional interest in higher-voltage op amps driven by industrial and automotive requirements.

A recent example is the TSB622, a general-purpose dual op amp from STMicroelectronics. This low-power, unity-gain-stable device operates over broad supply-voltage range of 2.7 to 36 V, enabling designers to use the same device for multiple applications with different voltage rails.

The dual device is automotive-qualified and specified over the extended temperature range of −40 to 125°C. The rail-to-rail output maximizes dynamic range while the low input-offset voltage of 1 mV ensures adequate precision for a low-power device.

With its gain-bandwidth (GBW) product of 1.7 MHz and maximum operating current of 375 μA per channel (with a 36-V supply), the TSB622 delivers high speed relative to its power consumption. Thanks to the low supply current, it will find homes in applications that demand low-power operation, extending the runtime of battery-operated equipment.

In addition, 4-kV ESD tolerance (HBM – human-body model) and enhanced resistance to electromagnetic interference ensure the TSB622 withstands the technically demanding industrial and automotive environments.

Package Parameters

Packaging also is an issue for designers focused on production-related issues on top of the basic design considerations of component selection, footprint, and debug. The TSB622 dual device comes in SO8 and MiniSO8 styles that save board space and can help reduce the overall cost of the PCB (Fig. 1).

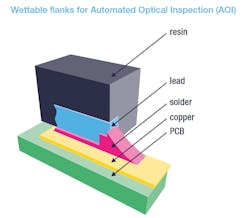

But there’s more to packaging than size and cost alone (although those are important factors, of course). ST notes that the 3- × 3-mm DFN8 package, which also will be available shortly, has “wettable flanks” that provide extra mechanical strength to meet the automotive-industry requirements.

This is needed because a standard, sawn DFN/QFN package has terminal flanks with exposed copper that can’t form a consistent side fillet when soldered. However, automotive applications require such a fillet to perform automated optical inspection (AOI) during assembly. ST claims they have adopted the most innovative solution on the market to meet this requirement (Fig. 2).

Furthermore, this packaging approach is immune to soldering cracking despite more than 3,000 thermal cycles at −40 to 125°C at one cycle per hour on a 1.0-mm-thick TG FR-4 PCB.

As is needed with op amps and other basic analog/linear components, the 26-page datasheet includes the many customary tables, performance graphs across multiple parameters, minimum/maximum specifications, absolute maximum ratings, and more.

There’s also a nice feature at the end of the datasheet: two lists, one indexing its tables and the other for its figures (Fig. 3). Both are very convenient to have when you’re looking through the datasheet for those factors that are most relevant to your design concerns. (Note that I have seen this low-tech but extremely useful index on datasheets from some other linear/analog-IC vendors, but not from all of them.)

The industrial-grade version of the TSB622 is priced at $1.12, while the automotive-grade version is $1.34 (1,000 pieces).

Reference

STMicroelectronics, “Automotive Standard Analog: Robustness and Performance”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.