Making MEMS Move Air and Fluids for Fun and Cooling

What you’ll learn:

- How piezoMEMS devices can make sound as well as cool things.

- How piezoMEMS works.

- What kinds of applications piezoMEMS technology can address.

Sensors Converge had a lot of interesting sensor and MEMS technologies on display. I had a chance to see some when xMEMS Labs’ Vice President of Marketing and Business Development, Mike Housholder, gave a demonstration of the company’s piezoMEMS technology (watch the video above). The technology has been employed in earphones as microMEMS speakers and to move air to cool semiconductors.

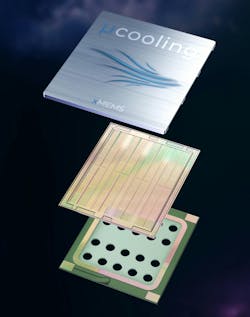

xMEMS fabricates its devices by adding a layer of piezo material on top of a movable MEMS substrate (Fig. 1). The piezo material changes shape when an electric field is applied. The other pieces to the puzzle include the control circuitry along with an ASIC designed to control the system. Developers can design systems that simply interface with the ASIC via a serial interface.

How piezoMEMS Works

Piezo devices can generate electricity based on mechanical strain due to deformation, or change their dimensions when an electric field is applied. Piezo devices have been employed in ultrasonic devices and sensors. xMEMS Labs used the characteristics of their piezo materials to move MEMS-sized panels.

xMEMS piezo system also includes a piezo-based valve that can be used with the air movement device. The two devices can be combined to provide precise control of air movement and pressure. The ASIC handles the details and systems can be configured to allow for bidirectional airflow that would be useful in some applications.

Some piezoMEMS Applications

Micro speakers for in-ear personal audio devices were the first application from xMEMS that utilized piezoMEMS technology. Larger speakers are now available with similar low-power characteristics, which includes providing a sealed system that’s ideal for field operation.

Cooling is accomplished by moving air past hot devices such as CPUs or GPUs, or solid-state disks (SSDs) like the M.2-based NVMe devices that are growing in capacity but generating more heat (Fig. 2). Conventional heatsinks take up more space than an active cooling system, which would occupy more space when using a conventional fan.

Developers using MEMS-based cooling tend to target applications that are in tight spaces where conventional fan-based solutions are impractical. xMEMS Labs’ solution has the advantage of high-pressure operation, allowing designers to create longer paths to route airflow. Fan-based systems, on the other hand, tend to be employed in spaces where there’s lower pressure but high volume that work best with straight-line air movement.

Air-based applications are the current target for MEM-based solutions, but they can handle liquid as well. This could lead to some interesting MEMS-based sensors and control systems that only need to move very small amounts of material.

>>Check out this TechXchange for similar articles and videos

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.