Steerable CMOS Sub-THz MIMO Array Combines High Density, Precision, Low Power

What you’ll learn:

- Why a reflective array offers benefits compared to active elements in a high-density array.

- How a binary phase-control scheme is used in place of conventional phasing for extremely low power, high-density tiling.

- How the system was tested for 2D and 3D performance.

There’s lots of interest and activity in the high-gigahertz/low-terahertz part of the electromagnetic spectrum for many reasons: available bandwidth, unique penetration characteristics, short wavelengths and high resolution, and small size, among others. But successfully channeling this energy is a challenge, as most applications require a highly steerable, controllable, very thin beam directed over a wide angle using a large number of elements in the array.

Now, a team led by recent Ph.D. Nathan Monroe at the Terahertz Integrated Electronics Group at MIT, in conjunction with Intel Corp., has devised and demonstrated a 98- × 98-element (let’s call it 10,000 elements) steerable sub-terahertz MIMO antenna array (Fig. 1).

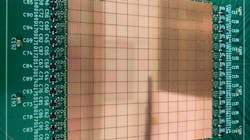

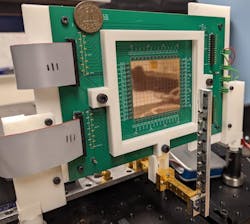

It’s fabricated as a tiled, “stitched together” CMOS device measuring 5.6 × 5.6 cm, using Intel’s 22-nm FinFET process. The final device was tested in a variety of radiation pattern and 2D/3D imaging arrangements and demonstrated a narrow 1° 3-dB beamwidth.

It's one thing to place all these antennas—however they’re fabricated—on a small footprint. It’s another to actually control them and their relative phasing to steer the beam. Conventional approaches would have shortcomings due to losses, inter- and intra-element routing complexity and congestion, and assuring phase synchronization. In addition, the size and power requirements for each individual antenna’s control can be overwhelming,

Leveraging a Reflectarray

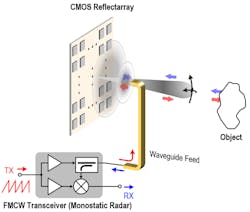

To overcome this, the team used a reflectarray, which is a reconfigurable mirror arrangement in which a feed antenna radiates energy onto the antenna array, and then those elements receive, phase shift, and radiate the energy (of course, the reciprocity principle works here for receiving as well) (Fig. 2). Its advantages over the conventional phased-array implementation include reduced distribution losses, improved phase synchronization, and no need for complex RF routing.

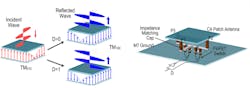

The next challenge was to control element phasing. Traditional approaches had high insertion loss (~10 dB), high power needs (~ 10 mW per element), and large size with a λ/2 footprint, along with excessive phase and amplitude errors, limited narrowband capabilities, and unidirectional signal handling.

Instead, they used a one-bit phase shifter with two passive FET switches to feed opposing sides of antenna and quantize phase to 0° or 180° (Fig. 3). This approach requires no static dc power, has low THz loss (~3 dB), and requires only a small area of about 10 × 10 μm2, among other attributes.

Challenge of Beamsteering

Steering the beam of energy is another problem, as computing and communicating enough bits to control 10,000 antennas at once would dramatically slow the reflectarray’s performance. The researchers overcame this problem by integrating the antenna array directly onto computer chips. Since the phase shifters are so small—just two transistors—they were able to reserve about 99% of the space on the chip for other purposes.

They used this extra space for memory, so that each antenna can store a library of different phases. Compared to prior reflect/transmit arrays employing discrete phase-shifting devices, this approach doesn’t require any high-speed control signals from external electronics, thanks to an 80-kbit shift-register memory integrated under each antenna.

“Rather than telling this antenna array in real-time which of the 10,000 antennas needs to steer a beam in a certain direction, you just need to tell it once and then it remembers,” said Monroe. “Then you just dial that up and essentially it pulls the page out of its library. We found out later on that this allows us to think about using this memory to implement algorithms, too, which could further enhance the performance of the antenna array.”

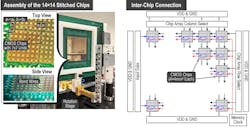

The reflectarray is implemented as a 14 × 14 tiling of identical 22-nm CMOS die, each designed to talk to copies of itself. Each die has an area of 4.4 mm2 and contains 7 × 7 antenna units. The overall aperture is 58.58 mm2, with about 780 Mb of built-in memory (for control, communication, and some processing). An identical pitch of about half wavelength is maintained among antennas both within chip and between adjacent chips (Fig. 4).

The chips are interconnected via low-profile gold bond wires at their edges. Power and phase data are provided from the boundaries of the assembly, and chip-select signals configure each chip to either accept incoming data or pass it onto its neighbors. This allows for high scalability and robustness to potential defective chips with negligible performance degradation.

Performance Tests

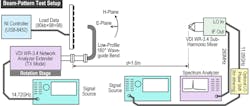

There are many figures of merit used to evaluate the performance of this type of arrangement and the team pursued many of them using a sophisticated arrangement (Fig. 5).

The tests included beam shaping for squint correction and sidelobe reduction. (“Squint” is the offset angle of the transmission/reception from the normal of the plane of the antenna; it’s a change in the beam direction as a function of operating frequency, polarization, or orientation and can limit the bandwidth of phased-array antenna system.)

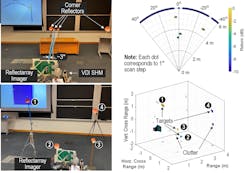

In addition to measuring beam patterns in the E- and H-planes as well as sidelobe reduction, they also performed 2D angular-resolution and 3D object-detection tests (Fig. 6). When used as an imager, the one-degree-wide beam moves in a zig-zag pattern over each point in a scene and creates a 3D depth image. Unlike other terahertz arrays that can take hours or even days to create an image, their array works in real-time, making it suitable for applications such as automotive imaging.

This work is funded by Intel Corp. through a Semiconductor Research Corporation Member Specific Research Grant to MIT, and by MIT Center of Integrated Circuits and Systems. It was presented at the IEEE International Solid-State Circuits Conference (ISSCC) in February 2022, as “Electronic THz Pencil Beam Forming and 2D Steering for High Angular-Resolution Operation: A 98×98-Unit 265 GHz CMOS Reflectarray with In-Unit Digital Beam Shaping and Squint Correction.”

Unfortunately, as with many conference papers and presentations, there’s no posted copy of the contributed items (either open access or even behind a paywall). As a result, many of these interesting conference contributions just “disappear” from any sort of availability for non-attendees even after the event, which is very frustrating and a technical loss to industry and academia (admittedly, you may be able to get a copy by contacting the authors directly as I did, but that’s a challenge).

However, lead author Dr. Munroe posted a four-minute video (see below) of their live demonstration at ISSCC, which gives some appreciation of the accomplishment:

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.