Solid-state LED illumination has been around for decades. But only over the past decade has it had an impact on indoor and outdoor illumination, where it has steadily gained a foothold with continuing albeit slow decreases in LED chip costs. The technology has the potential to significantly reduce energy use and costs.

Related Articles

- LEDs Line Up To Replace Residential Incandescent Bulbs

- Use A Flyback Topology To Drive Custom LED Lighting

- LED Lighting: Can Consumers Cope With The High-Priced Switch?

LED-based lighting product prices have decreased more rapidly than had been expected according to market research firm Yole Développment. It estimates that the 2013 packaged LED product market of $13.9 billion will reach $16 billion by 2018, driven mainly by general lighting applications.

Consumers today can buy LED light bulbs for as little as $9.95 from major outlets like the Home Depot, Lowe’s, and Walmart. However, there is some confusion about the various types of light bulbs available on the shelves besides LEDs, as well as the rating nomenclature on them. The federal Energy Independence and Security Act of 2007 requires LED light bulbs to deliver the same amount of light output using at least 25% less power than the other types of bulbs they would replace.

This file type includes high resolution graphics and schematics when applicable.

Efficiency Achievements

LED efficiency levels have risen to more than 160 lumens/W in the last decade. Cree has demonstrated in the laboratory a record 303-lumen/W white light at a correlated color temperature (CCT) of 510k and 350 mA. (The theoretical maximum output for LEDs is about 683 lumens/W.) Of course, a higher light output level comes at the expense of greater heat dissipation, leading to more thermal management.

Osram Opto Semiconductors is using Chip-on-Board (CoB) technology to offer LEDs with a luminous flux of 2000 lumens and an efficiency of 100 lumens/W from a light-emitting surface diameter of just 9 mm in a 15- by 15-mm package (Fig. 1). The compact Soleriq P9 is aimed at spotlight applications in retail outlets and museums.

At this year’s Light + Building Exposition in Frankfurt, Germany, Osram demonstrated what it claims is the world’s most efficient LED lamp, which achieves an efficiency of 215 lumens/W. That’s as much light output as what compact fluorescent lamps (CFLs) or LED tubes deliver, yet Osram’s lamp dissipates one-half the power. This record-setting efficiency is based on the use of high-efficiency red LED chips and green-whitish Osram-developed phosphor.

Yet progress in getting more LEDs into the public domain and in homes, buildings, and outdoor settings has been slower than what the technology has promised. Manufacturers have learned that for them to move forward more rapidly, they must deal with even more complex issues than just the chip’s cost. Manufacturing costs involving wafer materials, processing, and packaging are a big challenge and form a significant part of a light bulb’s cost.

Most recently, Cree introduced the first 800-lumen module intended to replace 150-W ceramic metal-halide lamps in convention centers, airports, auditoriums, and shopping malls (Fig. 2). It is aimed at high-ceiling applications and uses 63% of the power used by metal-halide lamps and lasts three times as long. “It allows us to effectively address high-ceiling, high-lumen applications without sacrificing color reliability and quality,” says Wesley Johnson, Cree’s product manager for Hi-Lite Manufacturing.

Still, LED light bulb prices have steadily narrowed the cost difference between LED illumination and incandescent and even CFLs. There’s no question that the energy and cost savings over a longer-term basis are key attributes of LED lighting sources compared to other sources.

This gain in price reduction has been the result of more advanced materials, better optics, smarter drive circuitry and controllers, and innovative thermal management methods. Helping all of this is the government’s mandate to phase out much less efficient incandescent bulbs and eventually CFL bulbs.

The Department of Energy’s (DoE’s) Energy Efficiency and Renewable Energy initiative has been a major driver. 100-W and 75-W tungsten light bulbs were phased out of the market a couple of years ago, and 60-W and 40-W bulbs will follow. Retailers, however, are allowed to sell off existing inventory.

Because luminaire, lamp, and trough lighting applications must satisfy many variable requirements in the area they’re illuminating, the LEDs within them must be designed to be flexible enough to meet those requirements. LED chip makers may find it more practical to begin a design from not just at the chip level, but also continue through to the application level. Optics adaptability to the application is just one example in need of tackling.

For instance, Philips Lumileds Lighting’s Luxeon Z family of un-domed micro-sized LEDs provides unmatched optical flexibility for precise light-beam control (Fig. 3). Just 13 by 17 mm in size, the one-step McCadam Ellipse warm-white LEDs enable unsurpassed color consistency, luminance, flux density, and design flexibility for future lighting solutions.

Flexibility for lighting fixture and other end users is a must. They need to have easy light-level adjustments, programmable control, dimming capability, a package form factor that fits the intended application, the right color rendering index (CRI), color-correlated temperature (CCT), and a package that fits the intended application. However, more light output is needed in a practical costs/lumen manner with enough white light output to fit the application.

“Lighting quality should be considered in a contextual manner. Sometimes, for example, a certain output lumen level is not suitable for a particular application,” says Derry Berrigan, co-founder and chairwoman of Light Think University, a non-profit organization that seeks to educate college students about lighting and realistic expectations in terms of other disciplines like architecture (see “Changing Technologies Require New Lighting Perspectives").

Medium-output and high-output LEDs are beginning to appear in a variety of applications, many of which showcase solid-state lighting (SSL) technology’s capabilities. Notable applications for outdoor and even indoor LED illumination worldwide are plentiful. LED flood lamps now wash programmable palettes of red, green, and blue (RGB) shifting colors across the exterior of buildings, tunnels, stadiums, and bridges around the globe at costs less than alternative lighting sources and with greater lifetimes.

The western span of San Francisco’s Oakland Bay Bridge, which celebrated its 75th anniversary in 2011 with 25,000 RGB lights, is just one of many examples. This type of lighting is reported to be more efficient than other lighting sources, lasts tens of thousands of hours, cuts the costs of replacing hard-to-reach burnt-out other types of bulbs, and requires only about $30 worth of electricity to power at night.

SSL is gaining more traction than CFL products, reports James Broderick, the DoE’s Lighting Program manager, and is being adopted much faster than the adoption of CFLs, although not as fast as consumer electronics technology. He credits action taken by the DoE’s Commercially Available LED Product Evaluation and Reporting (CALiPER), Gateway and Lighting Facts programs, various energy efficiency programs, and standards organizations that helped the LED industry avoid the problems that plagued CFL market development.

Late last year, the DoE allocated nearly $10 million to support LED R&D and manufacturing efforts for SSL as part of cutting energy waste and doubling energy productivity by 2030. The funding also includes funding for organic LED (OLED) technology efforts. The DoE expects the present roughly 150-lumen/W output levels to increase 250 lumens/W by then.

The DoE Caliper program has issued recent reports on MR16 and PAR38 lamps (http://www1.eere.energy.gov/buildings/ssl/news_detail.html?news_id=21316) and (http://www1.eere.energy.gov/buildings/ssl/reports.html) as a guide to help LED lighting makers and suppliers adjust to market conditions. The two lamp forms are popular housings used in the illumination market.

Which GaN Technology?

The use of gallium nitride (GaN) on silicon wafers is a mainstream way to grow LED chips. Another is GaN on sapphire. There is no clear sign which technology will be the front runner for the next few years, although many experts agree that both will prosper. There are also competitors like GaN on GaN, silicon carbide (SiC), and even indium gallium aluminum phosphide (InGaAlP).

Many major LED chip manufacturers including Plessey Semiconductor, Osram Semiconductor, Cree, Philips, and Sharp Corp. are using the GaN-on-silicon process. To ease the transition to GaN-on-silicon LEDs, Azzurro Semiconductor created a GaN-to-silicon wafer template. The company claims it achieved 3-nm wavelength uniformity in a production setting and 1 nm in the lab. Azzurro’s intellectual property eases the transition for GaN-on-silicon LED manufacturers, bowed wafers, and variable wafer thicknesses.

For those IC companies making GaN on sapphire, which is expensive and difficult to process, SemiLEDS developed and patented a technique without the use of any sapphire. The method significantly reduces the carbon footprint of the LED. It deposits GaN on a copper alloy (Fig. 4). The lack of sapphire also removes a thermal management bottleneck while providing an environmentally friendly LED.

Soraa has developed what it says is the world’s most efficient LED with its third-generation Gen3, which outperforms its nearest competitor by 20% at normal operating conditions, according to the company. Made using chip-on-board (CoB) technology, it provides unmatched efficiency and brightness, full visible-spectrum color, and whiteness rendering. It will be integrated into large form-factor lamps.

One indication of a market adjustment to reduce the cost of LED manufacturing is the move by Bridgelux Inc. to sell its GaN-on-silicon technology to Toshiba. This enables Toshiba to produce lower-performance LEDs using larger wafer-size GaN-on-silicon technology and leaves Bridgelux to concentrate on its core GaN-on-sapphire technology to make higher-performance LEDs on smaller wafers.

The Packaging Challenge

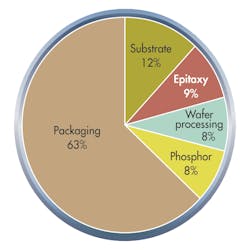

As market experience has shown, the packaging challenge is pushing LED semiconductor chip manufacturers (and there are hundreds of them) to work more closely with lighting product providers. The DoE recognized this challenge in its Manufacturing Roadmap for solid-state lighting and R&D workshop report prepared last September (http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_manuf-roadmap_sept2013.pdf).

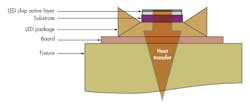

Packaging takes the biggest chunk out of the manufacturing process for an LED where costs associated with die-level packaging activities tend to dominate (Fig. 5). LED manufacturers must pay closer attention to it to realize greater cost savings, states the report. The DoE expects these packaging costs to come down to about 17% of 2013’s value by 2020.

As mentioned earlier, CoB technology is becoming more common in LED packaging. Bridgelux produces the V series (connector-less) and the Vero series (connectors) of LED chips using CoB technology. Bridgelux’s latest product is the Outdoor Lighting Module (OLM). “This represents a higher level of integration for outdoor lighting,” says Todd Farmer, senior marketing manager for exterior and industrial lighting. “It takes the CoB approach and integrates it with optical control, with outdoor environmental protection (IP66). It solves the capital expenditure problem by the way optics are designed.”

Luminous Devices Inc. also uses CoB technology in its Xnova LEDs, which deliver 145 lumens/W at 5000K and 132 lumens/W at 3000K at room temperature. The company credits its AccuWhite technology for delivering the industry’s best CI of 98.

Samsung is offering advanced flip-chip LEDs, the FC and FCOM, for packages and modules that offer a high degree of design flexibility and reliability for use in bulbs, packages, and downlights. The LED chips are flipped over and adhere to a phosphor film for each LED. There’s no need to place a plastic mold over each chip, as other companies normally do. This allows for packages down to a chip-scale size, enabling more compact lighting fixture designs.

Drivers Add Costs

LED lamps require driver circuits that can add significant costs for SSL. The challenge is to deliver a lamp with high-quality light at affordable costs, while meeting a high enough CRI and dimming capability similar to incandescent bulbs. Moreover, the LED lamp and its driver must be compatible with the dimming capability already installed in the home or building. And, it must provide flicker-free dimming with no shimmer. Several power semiconductor manufacturers are looking to solve this problem.

Fairchild Semiconductor’s FAN5346 boost LED driver supports pulse-width modulated (PWM) dimming. This asynchronous constant-current driver drives LEDs in series to ensure equal brightness for all LEDs. It’s available in two versions: a 20-V output for driving five LEDs (FAN5346S20X), and a 30-V output to drive eight LEDs (FAN FAN5346S30X).

Marvell Semiconductor says its 88EM8187 LED constant-current controller delivers unparalleled deep dimming performance and the industry’s highest level of integration in eight-pin and 14-pin small-outline IC (SOIC) packages. It features over 90% driver efficiency and the industry’s best regulation of less than 2% over a wide ac line voltage range.

With an eye on the future, STMicroelectronics has announced the STEVAL385LEDPSR evaluation board and reference design for intelligent LED-based streetlight designs. The design includes the STM8-microcontroller-based STLUX385A digital power controller IC, which can implement SSL driver functionality, and provides a variety of interfaces including network connectivity.

“Digitally controlled lighting is the key to saving energy in outdoor installations,” says Matteo Lo Presti, group vice president and general manager for STMicroelectronics’ Industrial and Power Conversion Division. “As grids get progressively smarter, cities will be able to control the streetlamps to produce even greater savings because all the key communications protocols are already incorporated in the STLUX385A.”

The IC integrates full support for a digital addressable lighting interface (DALI) network link. The peripherals integrated with the microcontroller can enable implementation of 0- to 10-V analog controls and interface with a variety of sensors. Digital communications facilities on-chip enable development teams to add Wi-Fi, ZigBee, and other network support with external ICs.

Sensity Systems (formerly Xeralux) is a pioneer in digital intelligent LED-based smart lighting networks. Its Light Sensory Network (LSN) luminaire portfolio comprises the first LED lighting products designed from the ground up for LSNs. Each luminaire supports a broad set of cloud applications with Sensity’s NetSense platform. The platform includes sensors and high-bandwidth networking that light owners can use to collect, monitor, analyze, and act on real-time information for improved lighting and for diverse applications such as public safety, environmental and weather monitoring, parking, and asset management.

“Lighting owners now have the ability to transform their lighting infrastructure into a strategic network capable of capturing data from the world around them—and using that data to improve everything from security to business profitability. We have truly entered the ‘Internet of Things’ era where people and businesses will be connected to one another through the objects around them in their everyday lives,” says Hugh Martin, Sensity’s chairman and CEO.

About the Author

Roger Allan

Roger Allan is an electronics journalism veteran, and served as Electronic Design's Executive Editor for 15 of those years. He has covered just about every technology beat from semiconductors, components, packaging and power devices, to communications, test and measurement, automotive electronics, robotics, medical electronics, military electronics, robotics, and industrial electronics. His specialties include MEMS and nanoelectronics technologies. He is a contributor to the McGraw Hill Annual Encyclopedia of Science and Technology. He is also a Life Senior Member of the IEEE and holds a BSEE from New York University's School of Engineering and Science. Roger has worked for major electronics magazines besides Electronic Design, including the IEEE Spectrum, Electronics, EDN, Electronic Products, and the British New Scientist. He also has working experience in the electronics industry as a design engineer in filters, power supplies and control systems.

After his retirement from Electronic Design Magazine, He has been extensively contributing articles for Penton’s Electronic Design, Power Electronics Technology, Energy Efficiency and Technology (EE&T) and Microwaves RF Magazine, covering all of the aforementioned electronics segments as well as energy efficiency, harvesting and related technologies. He has also contributed articles to other electronics technology magazines worldwide.

He is a “jack of all trades and a master in leading-edge technologies” like MEMS, nanolectronics, autonomous vehicles, artificial intelligence, military electronics, biometrics, implantable medical devices, and energy harvesting and related technologies.