In low-cost systems where inexpensive fans are used with no fan control, fan-failure detection is particularly useful. Fans running full-time use up their operating life more quickly than those that are run only as necessary or have their speed varied to suit cooling needs.

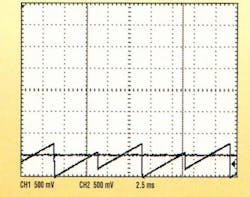

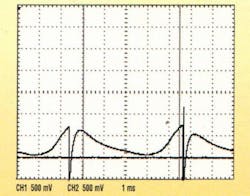

Fan-failure detection is complicated by the varying fan current waveforms—both in shape and offset. The only certain characteristic is that a properly running fan’s current waveform will have movement. Therefore, a circuit used to detect fan failure is simply a “current-movement” detector that ignores both offset and waveform.

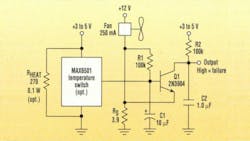

Figure 1 shows a circuit that accomplishes this by sensing fan current across the resistor RS. This resistor is selected based on fan current to develop a nominal dc drop of 0.7 to 1.5 V. R1 and C1 establish an average dc level at the midpoint of the transitions of the current waveform and apply this voltage to the base of Q1.

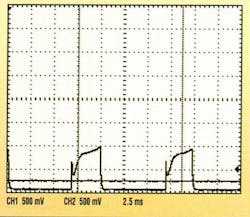

The current waveform and its accompanying transitions are fed directly to the emitter of Q1. As a result, the collector of Q2 starts to toggle current. Were it not for C2 and the relatively large value of the collector pull-up R2, the collector voltage also would toggle. As the collector instantaneously pulls down, the values of R2 and C2 mandate a long time (in this case, a tenth of a second) to pull up. Therefore, as long as the collector toggles at high enough rates, the output remains low. Stop the input wiggle and the collector will go high, indicating fan failure.

There are two possible upgrades to this circuit. One is accomplished by adding an optional temperature switch as shown in Figure 1. This backs up the fan failure detector by issuing a warning if the system reaches an excessive temperature for any reason (the fan failure detector cannot detect a blocked fan).

The second upgrade involves placing a 0.10-W resistor dissipating full power next to the temperature switch. This heater resistor, RHEAT, is in the fan airstream. It will rapidly detect a blocked fan, which inhibits the airstream past the resistor/temperature switch-combination.

This circuit will not work with certain fans equipped with locked-rotor sensing (typically the more expensive, up-market fans). If the rotor is stopped on these fans, they enter a shutdown mode and automatically attempt to restart about every half-second to second. (You can feel it in the rotor as you try to hold it locked.) Most fans, however, especially the low-cost types, have circuitries that are compatible with this circuit.

See associated figures 2, 3 and 4.