LED headlights for the masses

LED-based headlights have pretty much been features found only on such luxury cars as the Audi A8 and R8, Lexus LS 600h and top-line Toyota Prius. But that could be changing. A new universal light source could make it practical to put LED headlamps in even mid-priced vehicles, supplier Osram Sylvania says. Osram’s Joule-branded line of single-source LED lighting is designed to be as interchangeable from one vehicle to another as a conventional headlamp or taillight wedge bulb.

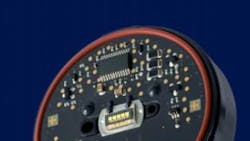

The standardized Joule forward-light source measures about 2 in. (50 mm) in diameter and a half-inch (12 mm) thick and contains an array of 0.4-in. (1-mm)-square high-brightness LED chips. Its first use was in dealer-installed fog lights for some Mitsubishi models sold in Asian markets. According to Wards Auto World, its initial use as original equipment will come in daytime running lights for an upcoming vehicle due in the next 12 months from a U.S. auto maker. Osram thinks use as a primary headlamp will come shortly after that.

One problem is that LEDs still can't put out as much light as conventional high-intensity discharge (HID) But because LEDs are more energy-efficient, Osram thinks its Joule system also could be an affordable option for use in forward lighting for electric vehicles and other high-mileage cars. The Osram LED system draws 14 W, while a halogen bulb requires 65 W. Volkswagen employed Osram’s Joule technology in the headlamps for its recent XL1 concept designed to deliver 235 mpg.

Another problem is that the design of the driver circuitry for LEDs is more involved than for ordinary incandescent lamps. But the plug-and-play design of Osram’s Joule device helps address this problem and lets automakers avoid having to design model-specific drivers.

Osram also says consumers would pay about $174 to replace its Joule signal-lighting system if damaged in an accident. That compares favorably with for LED array assemblies ($299) but is still higher than today’s incandescent assemblies ($131).

Osram thinks that by 2020, one in four cars worldwide will have LED headlamps, and half of all vehicles will use LEDs for rear signal lighting.

More info: http://ledlight.osram-os.com/