Capacitors tend to advance slowly, but these improvements are significant nonetheless. This month's feature “Overcoming PCMCIA Power Limits in Wireless Modem Designs” illustrates this point as it describes how newly developed tantalums can benefit pulsed-power applications. Similarly, other types of capacitors are undergoing steady improvements in performance, reliability and cost, which will benefit power-system designs.

Several of these improvements were described in a presentation given at the recent Power Technology Roadmapping Workshop, which was hosted by the Power Sources Manufacturers Association (PSMA). In his talk, “Capacitors for the Future,” John S. Bowers, a program engineer at Sandia National Laboratories, reviewed the development of various electrolytic and electrostatic capacitor types and assessed their impact on power-supply applications. His presentation examined the market demands influencing capacitor development and material changes that are enhancing performance. Based on these factors, Bowers extrapolated the levels of performance that might be expected from capacitors in the next few years.

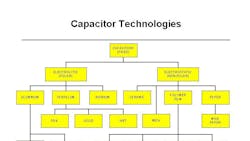

Bowers' talk encompassed aluminum electrolytics, tantalums, niobium oxide caps, as well as ceramic, mica and polymer film caps. Just keeping the various capacitor categories straight can be something of a challenge. To this end, Bowers provided a "family tree" chart of the popular fixed-value capacitor styles as a reference.

Bowers noted several industry trends that are influencing capacitor development. His list included the familiar ones such as lead-free design, Europe's Restriction on Hazardous Substances, and the demand for smaller components and integration. The latter, Bowers said, is mainly driven by the growing use of capacitors in portable products as these products continue to become more functionally complex. Bowers also noted that capacitors have some unique market requirements concerning reliability. For example, designers want capacitors to age “gracefully” and to fail benignly rather than catastrophically.Bowers provided more specific projections as he looked at different capacitor styles. For example, he noted that over the next three to five years, multilayer ceramic capacitors (MLCCs) will continue to achieve higher capacitance per unit volume with both X5R and X7R dielectrics. At the same time, increasing use of flexible terminations will make these capacitors less susceptible to cracking.

These improvements will benefit dc-dc converters, which already exploit MLCCs for their small size and low cost. For the isolated bricks, ongoing development will offer designers MLCCs with high C × V products within two years. Meanwhile, nonisolated converters will benefit from the availability of MLCCs with values as high as 200 µF in an X7R or better dielectric.

In the high power area around 1000 W, metallized polypropylene dc film capacitors are noteworthy because of their use in inverter applications. Bowers observed that over the next three to five years, film energy density should continue to advance at the current 4% per annum rate. He notes that this trend is important to customers because it affects both the size and cost of capacitors. At the same time, new dc film caps should help avoid meltdown as a failure mechanism.

Two design goals for suppliers of these capacitors will be to achieve high crystallinity and true 105°C long-life performance without derating the operating voltage of the parts.

Bowers projected that the energy-storage capability of metallized polypropylene dc film caps will rise from 0.3 J/cm3 at 900 Vdc in 2003 to 0.4 J/cm3 in 2008. These values correspond to volumetric capacitances of 0.7 µF/cm3 and 1 µF/cm3, respectively. Meanwhile, pricing will continue to fall, dropping from about 50 cents/J in 2000 to 15 cents/J in 2010.

Although the expected improvements in these and other capacitors are mainly evolutionary, they can have a great impact when combined with enhancements in other areas. Moreover, better capacitors open the door to use of advanced packaging concepts such as embedded passives and system-in-a package. And as is so often the case with passives, many little steps can add up to technology leaps.