Find a downloadable version of this story in pdf format at the end of the story.

The shunts employed for current measurements are typically connected in series with the load, and the voltage drop across them is measured. The current can be precisely ascertained since it is proportional to the shunt resistance according to Ohm's law.

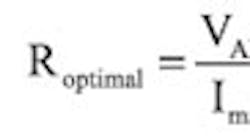

To minimize the shunt's effect on the rest of the system, the resistance chosen must be as small as possible. Yet, the voltage drop must be large enough to overcome noise and provide adequate resolution for the A/D converter or voltmeter. The optimal resistance value is thus achieved by taking into account of the largest possible current and the maximum voltage limit of the A/D converter. In other words:

VADC = Maximum limit of the A/D converter

Imax = Maximum worst-case current through the shunt

Once the optimal shunt has been selected, it is important to know the accuracy of the resistance value, since it affects the accuracy of the current measurement. Shunt accuracies are usually stated to range from 0.1% to 0.5% at room temperature. But few real-world applications are required to only operate at room temperature.

Shunts are rated by their maximum current and voltage drop at their maximum rated current. The nominal resistance of a shunt is typically less than a milliohm. For example, a 500A, 100mV shunt would have a nominal resistance of 0.2 milliohms at room temperature. Specialized equipment is needed to accurately measure such small resistances.

Even if we could measure such small resistances, it is the change in resistance that we actually care about. Suppose we know that the resistance of our shunt will change by 20% at the extreme operating temperatures of our application. If the shunt is nominally 0.2mΩ at room temperature, a 20% change is equivalent to 0.2mΩ × 0.20 = 40µΩ. If getting accurate readings in the milliohms is a challenge, measuring down to the micro-ohms range is impractical. How do we determine the effects of thermal drift in our application? Fortunately, there is a way to determine this without direct measurement.

Continue on next page

To solve our dilemma, we turn to physics. Suppose we have a bar of material with width wo, thickness to, and length Lo at some nominal temperature. Let's assume the bar has a constant cross-sectional area of Ao=woto. The resistance across this bar is given by:

Where:

ρo= Resistivity of the material at temperature.

Similarly, the resistance of the bar at temperature is:

Where:

w= Width

t= Thickness

A= Cross-sectional area

L= Length

The change in resistance due to thermal drift is:

If we want to know the percent change in resistance, we simply divide the above quantity by the nominal resistance:

The dimensions at temperature T due to thermal expansion and/or contraction is:

Where:

α= Linear coefficient of thermal expansion

Continue on next page

If we substitute these relations into equation (7), we can derive an expression for the percentage change in resistance for any shunt of any material. In other words:

Equation (13) represents the generalized formula for percent resistance change due to thermal drift. If this formula has not been previously derived, the author would like to name it Tong's Resistance Formula.

Note that from Equation (13) the change in resistance is completely independent of geometry. The effects of thermal drift are purely a function of material properties. This means a shunt could be designed with any random shape and it would have no effect on its performance due to thermal drift.

If we choose To to be room temperature, published values of ρo are readily available from many sources including the web. The real question is how do we determine ρ=ρ(T)? In practice, the difficult part of using Equation (13) is figuring out an appropriate value for ρ.

In general, resistivity increases with increasing temperature for conductors, and decreases for insulators. Wouldn't it be nice if there was a universal formula for ρ(T) that worked for all materials? The good news is that such a formula actually does exist. It ís called the Bloch-Grüneisen formula, and it has the form:

Where:

ρ (0)= Residual

C= Constant

ΘR= Debye temperature

n = Integer that depends on the nature of the electron interaction

Continue on next page

The bad news is that this equation can only be truly understood with a background in quantum mechanics.

For many metals, however, you can approximate ρ(T)with a simple linear function near room temperature:

Where:

β= Linear temperature coefficient of resistivity [1]

The published values for β are typically taken at room temperature, which is quite convenient for a host of applications. Fig. 3 shows a plot of the resistivity dependencies on temperature for the metals Titanium, Zirconium, and Hafnium. Notice that the plot is linear above temperatures of 100K. This is typical behavior of most conductors. The plot is nonlinear only at cryogenic temperatures.

So, unless you are dealing with a cryogenic application and do not need to account for extremely large values of ΔT, say ΔT <100°C to be conservative, Equation (15) is valid. If we plug Equation (15) into Equation (13), we get:

The values for α and β can be acquired from many textbook sources and are also available on the web.

Fortunately, the behavior of most materials that you will likely encounter in your career can be accurately approximated with Equation (16). A few such examples are tabulated in Table 1 for a temperature difference of ΔT=50°C.

MANGANIN, CONSTANTAN MAINTAIN RESISTANCE

Note that the value of ΔR/Ro is not necessarily positive for ΔT, even for metal alloys. Also, notice that the percent resistance changes for both manganin and constantan are almost nonexistent. This is the reason why you will typically find them used as the material of choice in shunt resistors. In fact, you do not even need to buy a shunt to get accurate current readings. All you need is a bus bar made of manganin or constantan with the appropriate dimensions so that it has the optimal resistance for your application. The beauty of being able to compute ΔR/Ro for any material is that we are no longer beholden to shunt manufacturers.

Continue on next page

Alternatively, you can even use less expensive materials such as aluminum. As long as you know the temperature of the bus bar, you can precisely determine its resistance with equation (16). Thermal feedback can be easily accomplished by employing a thermistor, voltage divider, and a spare A/D converter on your favorite microcontroller. Fig. 4 depicts such a setup.

ADD TEMPERATURE SENSOR

A proven way of ensuring system reliability is to add a temperature sensor in the circuit. A temperature sensor adds wiring to increase the system's complexity. On the positive side, the sensor reduces the cost of the system, as it eliminates the need for the designer to use a more expensive shunt in the circuit.

The benefit of using a less expensive shunt benefits designers of aerospace equipment, where reducing the weight of the aircraft or spacecraft is absolutely critical to ensure performance. With a knowledge of equation (16), an existing bus bar within the avionics systems can be utilized as a shunt, without having to increase the weight of the vehicle.

Electric vehicle battery charging circuits present a number of challenges to design engineers. The good news is that a knowledge of shunt effects, coupled with some relatively simple circuit modifications, can minimize the effects of shunt resistor thermal drift, freeing design engineers to focus on other battery circuit design tasks. The theory presented in this article provides designers with an efficient means to mitigate the effects of shunt resistor thermal drift.

The author would like to thank the following people for contributing to this paper: Roger Khourey, Alex Kwan, Bob Litjen, Noel Godinez, and Tom Orilicki.

REFERENCES:

-

Wei Gao, Nigel M. Sammes, An Introduction to Electronic and Ionic Materials,World Scientific Publishing Co. Pte. Ltd., 1999. pp.9.

-

James R. Chelikowsky, Steven G. Louie, Quantum Theory of Real Materials, Kluwer Academic Publishers, pp.220.

-

Griffiths, David. Introduction to Electrodynamics, 3rd edition. Upper Saddle River, New Jersey: Prentice Hall. pp.286.

-

Giancoli, Douglas C. Physics: Principles with Applications, 4th edition. London: Prentice Hall.

-

John O'Malley. Schaum's outline of theory and problems of basic circuit analysis, McGraw-Hill Professional, pp.19.

-

Serway, Raymond A. Principles of Physics, 2nd ed. Fort Worth, Texas; London: Saunders College Pub. pp. 602.

Find a downloadable version of this story in pdf format at the end of the story. Download the story in pdf format here.