Switched-mode power supplies (SMPS) and low dropout (LDO) regulators are found in electronic systems. Critical SMPS requirements include a stable output voltage with load current, good temperature stability, low ripple voltage and high overall efficiency. One difference between SMPS and LDO is in the power dissipation. When the SMPS switch turns on there is a low voltage drop across the switch, thus the voltage times current (V x I) produces low power dissipation. When the switch is “off”, there is a leakage current flowing in the switch, again V x I results in low power dissipation. The LDO is simpler to implement than an SMPS. As seen in Fig. 1a and 1b, both include an output capacitor.

Key characteristics for output capacitors are:

- Capacitance

- ESR (effective series resistance)

- ESL (effective series inductance)

- Frequency dependence

- DC and AC voltage dependence

- Temperature dependence and performance at operational temperature

- Time stability and aging effect - loss of capacitance and increase of ESR with time

- Suitability for an SMPS switching higher than 1MHz

- Physical size

The importance of these output capacitor characteristics depend on the type of the circuit and its end application. Volumetric efficiency, leakage current (for battery operated devices) and cost may also play a key role in the output capacitor selection process. Depending on the application and required transient response, generic SMPS requirements include the output capacitance value, low ESR and physical size. LDO designers may specify a limited ESR range for stable operation.

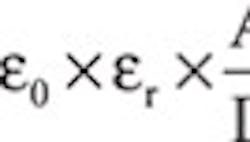

Among the most common output capacitor technologies are tantalum, tantalum polymer, niobium oxide, MLCC (multilayer ceramic capacitors) and aluminum electrolytic capacitors. The basic capacitance equation is:

Where:

C = capacitance

e0 = permittivity of vacuum

er = relative permittivity (material constant determines how many times the dielectric is better than vacuum)

A = surface of electrodes

D = thickness of dielectric

Based on Equation (1), achieving high capacitance in a small package requires a large electrode surface area, thin dielectric layer and high material constant (relative permittivity). The capacitor construction and materials are used to define the electrode surface area, dielectric thickness, permittivity, leakage current and its behavior with time, frequency, voltage and temperature, etc.

Conventional tantalum capacitors with a MnO2 second electrode provide excellent steady state reliability. Thanks to an extremely large surface area, thin dielectric, and stable material constant, the conventional tantalum capacitors are the premium choice for applications requiring:

- Maximum capacitance at minimum space such as mobile phones, cellular phones, etc.

- High reliability and long life time for systems including telecommunication (base stations), military, medical and aerospace applications.

The downside is tantalum’s ignition failure mode. It is recommended to use appropriate derating (i.e., use lower application voltage than the rated voltage) in high surge current circuits. Output capacitor applications may not be an issue as the power supply feedback is controlling the current and thus tantalum capacitors can be used here at up to 80% of the capacitorsí rated voltage (20% derating minimum) [1].

The most frequent field failures reported for tantalum capacitors are caused by applications with excessive current surge. It is always important to evaluate the worst-case scenario of current spikes and think twice about pushing the performance limit of a capacitor.

Circuits with an inductance in series with a high value capacitor may cause high voltage spikes when encountering low impedance switching. Mission critical operations should consider adding a diode in parallel with the capacitor for high voltage spike prevention.

Tantalum Polymer Capacitors

The second electrode in tantalum polymer capacitors consist of a conductive polymer (CP) material instead of MnO2 that provides much lower ESR performance. It also significantly reduces the ignition failure mode of the MnO2 tantalum capacitors. Performance characteristic constraints include limited voltage, ten times higher leakage current, relative cost, lower operating temperature range and resistance to humidity. The capacitors may be ideal for small power supplies in consumer applications like cellular phones, where it provides high ripple current capability and safety in the smallest case sizes [2].

Niobium Oxide (NbO) capacitors provide much higher ignition resistance and reliability compared with tantalum. This characteristic, combined with high reliability, has been recognized by leading companies making PC servers, automotive, on board aircraft control and home entertainment. The high performance versus cost value has been also recognized in notebook and industrial applications. The limitation is mainly in lower voltage range (10V capacitors with 20% derating = 8V application voltage maximum [2].

Multilayer ceramic capacitors (MLCC) feature electrodes and dielectric material deposited on a flat planar layer structure. There is a greater choice in dielectric ceramic material types, depending upon the capacitor performance requirements. The multilayer architecture supports extremely low ESR. The basic types are NPO/COG where capacitance values / permittivity is low (7-75), but the device is stable. The high capacitance is achieved by ceramic dielectric barium titanate (BaTi) dielectric with high permittivity (2000-4000) for X5R/X7R/X8R capacitors or even higher (~10,000) in the case of Y5V dielectrics. However, permittivity of each dielectric material and the final capacitance is strongly influenced by the other parameters, namely DC voltage, AC voltage, temperature and time (aging effect). BaTi dielectric devices also exhibit a piezo effect that may cause some noise degradation of the filtered signal by external vibration. The capacitors can even emit some audible and electrical noise. Their small case sizes and low ESR make these capacitors ideal for small power supplies with high ripple current output. Unlike the other high capacitance technologies, MLCCs are non-polar; thus there is no risk of reverse placement as in the case of the electrolytic capacitors [4] .

Advantages of aluminum foil capacitors include a wide range of voltages and capacitance and their lower cost. The disadvantage of the classic wet electrolyte is the high capacitance drop and ESR increases at lower temperatures, limited lifetime and aging effect (loss of capacitance over time). New aluminum technologies that replace the wet electrolyte with gel or conductive polymer provide lower ESRs, however, their cost is usually higher.

SMPS Capacitor Selection

Apart from the direct capacitance and ESR value of the output capacitor, any selection guide should reflect other parameters such as:

- Load characteristics and sink current

- Associated inductor value

- Converter switching frequency

- Consideration of parallel capacitor designs with the same or different technologies for optimum ESR and ripple demands

Although SMPS are usually stable, in some cases an ESR value that is too low, (such as with MLCC output capacitors), may cause instability and oscillations. It is always better to check the IC datasheet first and then prove with testing, as some of the power supply ICs may be insensitive to this phenomenon [3] . In many cases, the optimum solution is to use a parallel combination of two technologies, such as tantalum, with high capacitance and higher ESR and small MLCC with smaller capacitance and low ESR.

LDO Capacitor Selection

Older LDO designs were sensitive to ESR levels that ideally matched with tantalum and NbO capacitors. The new generation of LDOs can work with even lower ESRs and it can accept MLCC capacitors with its extremely low ESR values (Fig. 2). However, it is good practice to carefully check the stable ESR range of the LDO in all operational modes, especially at higher temperatures where the ESR of the capacitors is often much lower compared to room temperature.

Which capacitor technology is best? It is still difficult to answer in general terms. It is not surprising that there is no ideal power converter type and there is no ideal capacitor technology that would provide an ideal power solution. Table 1 summarizes these finding and it can be used as a “first look” guide for output capacitor selection to achieve stable and reliable operation. Sometimes, combinations of capacitor technologies in parallel combination may be a solution closer to the optimal operational performance.

References

- T. Zednicek et col. Voltage Derating Rules for Solid Tantalum & Niobium Capacitors, http://www.avx.com/docs/techinfo/voltaged.pdf

- T. Zednicek, Tantalum Polymer and Niobium Oxide Capacitors, http://www.avx.com/docs/techinfo/newtant.pdf

- R. Faltus et col. DC/DC Converter Output Capacitor Benchmark, CARTS Europe 2008, Helsinky Finland

- H. Kishi, Y. Mizuno, H. Chazono, BME MLCC Past, Present and Future Perspectives, Japanese Journal of Applied Physics Vol.42, Pg 1-15.

Related Articles

High-Voltage Tantalum Capacitors for +28-V Apps