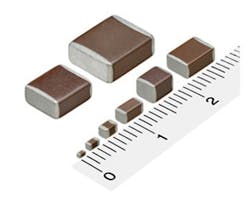

Soft-Termination MLCCs With High Flex Cracking Resistance

TDK Corporation introduced a series of soft-termination MLCCs that are specially designed to withstand flex cracking caused by bending stresses to the PCB. a wide range of capacitance values on a par with TDK's other commercial grade MLCCs. With these new types the soft-termination technology already proven in automotive grade components of the CGA series is now available for general-purpose applications as well. Mass production will start in July 2014.

PCBs are exposed to mechanical bending stress during a number of handling processes such as board splitting, insertion of sockets and leaded components, and screw-down, which take place after the MLCCs are mounted on the board. These mechanical stresses can cause flex cracking in the MLCCs. In order to effectively absorb these board stresses, TDK has designed the new types with an elastic conductive resin electrode material and advanced electrode forming technology. The result is a soft termination that is able to withstand a board deflection of up to 5 mm (over a length of 90 mm) - making the joint 2.5 times stronger than that of standard MLCCs - and all but eliminates the risk of flex cracking.

The new series of commercial grade soft-termination MLCCs extends TDK's portfolio of components with outstanding joint reliability. Together with the MEGACAP Type series of capacitors with metal lead frames, TDK offers a broad range of MLCCs that are able to withstand severe environmental conditions.

Flex cracking: After MLCCs have been soldered to a PCB, handling processes such as board splitting, insertion of sockets and leaded components, and screw-down can cause the PCB to bend, and the accompanying tensile stresses can lead to cracks in the MLCC itself.