Addressing Connector Challenges for VITA 100

What you’ll learn:

- What is VITA 100?

- Why VITA 100 needs new connector technology.

- What kind of performance will VITA 100 deliver?

VITA’s latest standard push is VITA 100. It’s designed to take military, avionics, and rugged applications into the next decade, providing more power and delivering high bandwidth. VITA 100 builds on the existing OpenVPX standards. These are used by The Open Group and the SOSA Consortium, which have built the SOSA standard for military applications

I was introduced to VITA 100 at VITA’s Embedded Tech Trends. Mike Walmseley, Product Management/Industry Standards at TE Connectivity, gave a presentation on the connectors to be utilized by VITA 100 (watch the video above).

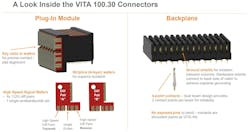

VITA 100 requires a new set of connectors to handle the higher bandwidth and higher power requirements. It delivers 4X the data rate when compared to VITA 46.30 VPX connections. The new standard continues to use the stripline, wafer connector approach (Fig. 1). It allows for high-speed differential signals to be handled by the plug and socket, with the ability to handle four 11G differential pairs on a wafer.

The backplane connector is shrouded, so there are no exposed pins to bend. Ground shields provide isolation between columns of pins.

More Power with VITA 100

The VITA 100.30 connectors are designed for high-speed signals and low power delivery on the order of 45 A. MULTI-BEAM Plus contacts can be used to deliver up to 100 A per contact (Fig. 2). Isolation fins provide clearance for high-voltage levels.

With the wafer approach, sockets and connectors can be configured as needed for applications. Not all boards will require large amounts of power, but they can be configured when needed. This is especially important when dealing with chips like large FPGAs, GPGPUs, and artificial-intelligence (AI) and machine-learning (ML) accelerators.

The new 4U VITA 100 board form factor is designed to handle such chips in a form factor that’s smaller than the 6U, but with double the space compared to the 3U standard. 3U and 6U were the only standard form factors prior to VITA 100.

VITA 100 Optics Integration

Chiclet-based optical transceivers (CBOTs) are likely to find a home with VITA 100 (Fig. 3). VITA standards for optical transceivers include VITA 66.1 and 66.4. However, the new approach provides separable expanded beam interface support. One possibility is building lasers and drivers into the connector.

Though VITA 100 is just starting out, it’s being developed rapidly as the demand for high-performance systems continues to rise. Fiber optics will have a more important role to play in the future, but the boards and connectors are still able to provide significant gains using copper connections.

>>Check out these TechXchanges for similar articles and videos

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.