Thermal Interface Material

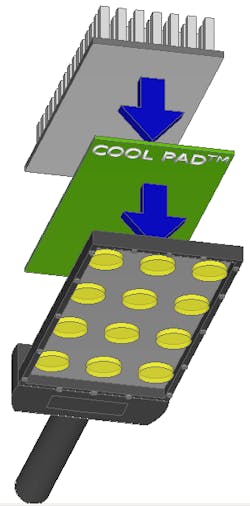

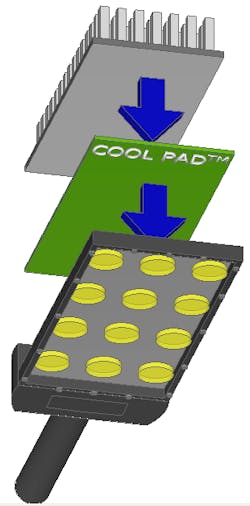

AI Technology, Inc. (AIT) introduces COOL-PAD(tm) CPR7154, a new class of thermal interface material that dispenses like a thermal pad, but performs with characteristics like that of a grease or gel when device temperatures increase to above 45°C. COOL-PAD™ CPR7154 is optimized to accommodate large areas with different heights and gaps of less than 3-mil along its interfacing area. It is filled with a modified oxide mixture and is electrically insulating at normal voltage. It is designed to have high compressibility as applied in comparison to traditional thermal pads. Once the device temperature reaches 45°C, COOL-PAD™ CPR7154 "melt-flow" fills even the smallest amount of trapped air along the interface between the device and heat-sink or heat-spreader.

A mechanical fastener of 5 psi or more is recommended to provide intimate contact between the COOL-PAD™ and the interfacing surface. Because COOL-PAD™ is compressible, it will fill in uneven height differentials and warps between the mating surfaces. The ultimate performance of COOL-PAD™ is achieved after the first cycle of melt-flow phase-change at 45°C or automatically when the device heats up during operation or with externally applied heat if the device is not anticipated to reach 45°C .

COOL-PAD™ CPR7154 is designed for thermal interface applications to withstand the worst of temperature and moisture exposure in outdoor LED luminaire applications with modules from Philips, Cree, Bridgelux, etc. Of course, the same phase-change pad works great for CPU and GPU in Xbox360, Play Station, and other game consoles. COOL-PAD™ CPR7154 is also ideal for CPU modules and graphic card interfaces in laptops and desktops such as Asus, Samsung, BenQ, Foxconn and other OEM.