The Next Decade of Tactile Sensing: Apps Driving the Future of Tactile Sensors

What you'll learn:

- How tactile sensing is solving real-world challenges in medicine, transportation, defense, and consumer products.

- Examples of innovative applications improving safety, performance, and user experience across industries.

- Emerging use cases that will expand adoption.

Many markets, from medical to transportation, take advantage of tactile sensors. This article looks at how these industries apply them.

Medical Applications for Tactile Sensing: From Clinical Settings to Portable, Wearable Devices

Tactile sensors abound in the medical arena, from clinical settings where physical therapists are using them as part of a system to assess patients’ foot pressure and gait, to manufacturers embedding tactile sensors into custom insoles aimed at improving foot function.

Researchers at universities are utilizing the technology to characterize skeletal motion and dynamics, while manufacturers investigate the feasibility of embedding it into smart seats and beds that sense pressure and movement. Figure 1 illustrates tactile sensors embedded into an occlusal analysis system used in dental offices worldwide to help assess patient bite force.

Medical device manufacturers have embedded tactile sensors into devices as part of drug delivery systems. Smart textiles are becoming more popular for sports applications as well to measure foot placement dynamics, bicycle seating uniformity, handle grip pressure, breathing rate, and even saddle-to-horse pressure distribution.

Transportation: Widespread Adoption Plus Niche and Emerging Applications for Tactile Sensing

Market adoption of tactile sensors in the automotive industry has always been significant, and demand is growing with the emphasis on electric vehicles and the new design considerations they bring. Tactile sensors are embedded into automobile seats to sense passenger presence and weight, in instrument touchscreens, and other controls.

Tactile sensors are used in safety tests to measure seatbelt pressure distribution, seating dynamics during vehicle acceleration and deceleration, steering wheel grip pressure, and in sensor-instrumented crash dummies. Automotive engineers also rely on tactile sensors to measure sealing pressure of doors (Fig. 2) and engine blocks, brake pad contact, and even tire tread dynamics. These represent just a few of many applications for tactile sensing in automotive research and design.

Similar applications also can be found in other forms of transportation, including marine and aerospace environments. Many unique applications have been applied in those environments, too, such as measurement of ice pressure against boat hulls for ice breakers, understanding the distribution of pressure against the body in pressurized space suits, or sensing forces against seats during high G force acceleration in jet aircraft.

>>Check out the other parts of this series

Understanding pressure distribution in lithium batteries during charge and discharge cycles is important for safety and performance in everything from mobile phones to electric vehicles. New advances in lithium battery technology are critically linked to mechanical heat and pressure dynamics, which require tactile measurements during design as well as manufacturing (Fig. 3).

Tactile Sensing in Industry and Research

In industrial markets, tactile sensors are embedded into industrial machinery to measure contact pressure distribution for a variety of feedback control applications. Pressure distribution is also important for maintenance and quality control to measure a range of factors.

These include proper heatsink contact, gasket and seal effectiveness, industrial brake contact surface distribution, nip roller alignment (Fig. 4), contact uniformity across surfaces for wafer polishing, and to dynamically measure pressure changes on surfaces of batteries and other products over time.

In consumer markets, tactile sensing is most common in touchscreen devices, but it can also be found in a variety of other applications. Tactile sensors that measure surface pressure have been embedded into power tools, gaming controllers, lock mechanisms, and consumer foot measurement for custom engineered shoes and boots (Fig. 5).

Tactile sensing is widely used in product research to measure such things as virtual-reality (VR) goggle face contact pressure, proper mating and sealing of smartphone cases for design or quality control, or to analyze golf swing balance and hand-grip pressure to enhance skills.

In robotics, tactile sensors provide the sense of touch so vital to appropriate handling of objects, such as in industrial manufacturing applications where improper handling of components during assembly can be costly. Hence, usage in robotics and drones is increasing mainly to measure and control grip forces for robotic hands or grippers, or drone package pickup and carriage.

Other tactile measurements are being explored in robotics, including sensing of slippage during grip, and surface “roughness” and “squishiness,” useful for distinguishing between different types of vegetables or ripeness, for example. There’s also growing interest in foot and gait pressure and movement sensing for autonomous “walking” robots. Tactile sensors have been explored to help the robot exhibit better balance and a more human-like gait (Fig. 6).

In the defense markets, tactile sensors have been employed to measure backpack-carrying load and stress as well as foot insole and gait stress during infantry operations, applied to body armor and helmets for impact testing, and test ejection seat force distribution to measure balance and grip for firearm research and training (Fig. 7).

During paratrooper and fast rope insertion or medical evacuation, sensors have measured body contact pressure for harnesses and stretchers. In the growing field of “Soldier Systems,” tactile sensors are used in smart textiles for real-time monitoring of breathing rates and gait analysis to sense vital signs for impairment due to potential injury.

Finally, R&D has always been a strong adopter for new sensing technologies by corporate, government, and university labs for conducting research involving tactile measurements or embedding into new emerging applications. In this arena, tactile sensing has deployed in many thousands of applications.

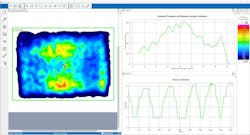

Sensors and electronics can be modified or customized for a large variety of research applications to measure tactile characteristics in static contact environments or real-time, and be integrated with laboratory systems such as LabVIEW or MATLAB for analysis and integration with other data. In the case of pressure mapping, these thin-film flexible sensors enable researchers to visualize contact pressure across a surface area dynamically — a trait that would otherwise be unobservable.

>>Check out the other parts of this series

About the Author

John Jutila

CEO, Tekscan

John Jutila is CEO of Tekscan, a global leader of tactile sensor solutions. John previously held CEO positions at Ripley Tools, a supplier of infrastructure installation solutions, and Champion ONE, an optical networking technology company, as well as several positions at Nokia, including VP Strategy & Operations for Global Strategic Alliances, COO of the Strategic Industries Division EMEA Region, and North American Division President for Optical Fiber solutions.

John has also held key executive positions at Asahi Kasei/Polypore for microporous membrane technology, InterDigital for advanced mobile phone technology, and HP/EDS for IT outsourcing. He holds a DBA from Grenoble Ecole de Management, an MBA from the University of Toledo, and a BBA in Venture Management from The Wharton School.