PCB Design Tool Handles Advanced Placement and BOM Chores

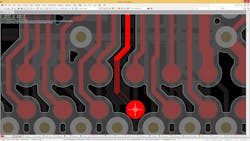

Altium’s latest printed circuit board (PCB) design tool, Designer 16, incorporates a range of new features including a new component-placement system and an alternate parts-choice system. The improved clearance support (Fig. 1) visually highlights adjacent areas that are out of bounds. This makes it easier for a designer to see where and why a new path may or may not be allowed. The highlights change when a new signal path is chosen. Additionally, it helps to cut down on design time by clearly defining boundaries. Also, it helps designers cut down on design errors because they know where boundaries are located.

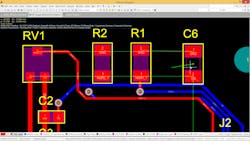

Dynamic placement of components is a standard job in PCB layout (Fig. 2). Altium’s Designer 16 provides snap-to alignment using multiple points on a component. This allows quick drag-and-drop positioning resulting in a properly aligned design. The system can push other components as necessary instead of dropping a new component on top, which will require corrections in the future. One thing that should be commented on is size constraints making this necessary. They have to cram more and more components into smaller spaces. This helps ensure everything can fit nicely and be spaced efficiently.

Every PCB project has a bill of materials (BOM) and typically a designer creates the PCB layout using one part for each component. This is great if there is a fixed BOM, but often companies prefer to have alternate sources for parts. They will often build using pin-compatible parts. This handling of alternate components was often done after a design is complete. A designer would have to keep in mind any alternate choices using external tools like spreadsheets or their own memory to track the options. To add, you can set specific backup parts if your first choice is out of stock. If the product is out of stock, Altium Designer 16 automatically moves on to your second choice, ensuring there is no time wasted looking for a compatible part (Fig. 3). It provides more control over what parts will be interchangeable and optionally adjust the part number if an alternate is used.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.