Check out more TechXchange Talks videos.

What you’ll learn

- How FPGAs can enhance motor control.

- What technology was used to shrink the module size.

- Where the K24 fits in AMD’s Kria family.

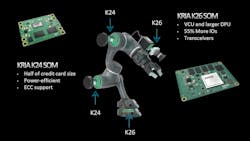

AMD’s Kria family of system-on-modules (SOMs) and kits started with the K26 that targeted vision and robotics control applications. The new K24 SOM is more compact by taking advantage of TSMC’s Integrated Fan-Out (InFO) wafer level packaging (Fig. 1). I talked about the K24 at length with AMD’s Senior Director, Industrial, Vision, Healthcare and Sciences Markets, Chetan Khona (see the video above). The K24 targets motor-control applications and supports artificial-intelligence (AI) and machine-learning (ML) applications.

The K24 uses less power and only requires a heatsink, making it easier to incorporate it close to motors that it might be controlling. The SOM's smaller form factor is plug-compatible with the K26. One of the application areas targeted by the K24 is intelligent motor control, while the existing K26 SOM eyes higher-end applications like machine vision and robotic planning (Fig. 2). The K24 and K26 are based on AMD’s Zynq multiprocessor system-on-chip (MPSoC).

The Zynq processing cluster includes a quad-core Arm Cortex-A53, a dual-core Arm Cortex-R5F, along with a Mali-400 MP2 GPU. The video codec unit (VCU) supports up to 32 streams with a total resolution up to 4Kp60. The on-chip FPGA offers the customization to handle tasks from motor control to running ML and AI models. It can also provide customized time-sensitive networking (TSN) support that's very useful in industrial communication applications.

The KD240 Drives Starter Kit is built around the Kria K24 COM. The carrier board exposes the peripheral interfaces (Fig. 3). This includes a range of serial interfaces including CAN as well as multiple Ethernet ports with TSN support. The motor-control support differentiates this platform from the other K26-based kits. AMD’s Kria app store has been expanded to address the motor-control aspects of the KD240. It includes applications like adaptable, sensor-based, and sensorless field-oriented control (FOC).

The K24 platform is capable of running Linux and the Robot Operating System 2 (ROS). This modular system can cooperate with other ROS nodes within a network. A typical advanced robot might use a TSN Ethernet network to link multiple K24 and K26 modules using ROS.

The starter kit can be enhanced using either of the two accessory packs for the K24-based platform (Fig. 4). The KD240 Motor Accessary Pack includes a 10,000 RPM BLDC motor from Anaheim Automation, which integrates a quadrature encoder. The Rev Robotics 2-in-1 Motor Kit Accessory has a BLDC motor as well, but no encoder. It features a simple robotic arm that can be combined with an ML/AI vision system to construct an intelligent ball shooter. This platform is designed to highlight sensorless, field-oriented, accelerated control applications.

The kits and app store provide pre-built and configured motor-control and DSP applications. These may be sufficient for many who want to focus on software development while taking advantage of the capabilities of the Zynq MPSoC and the FPGA. The Vitis open-source development environment is designed for this type of development. It focuses on the on-chip processors, providing a software development environment that can easily load FPGA support and access and control it in software.

Developers who want to create or enhance the FPGA firmware can utilize AMD’s Vivado, which integrates Vitis. Fine-tuned designs can be created using RTL. It also works with the Vitis High Level Synthesis (HLS) tool that's able to turn C code into RTL.

Links

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.