Efficiency in Coreless Servomotors

Most servomotors have an efficiency in the range of 50 to 60%. But it is possible to devise positioning-motor architectures that deliver far better efficiency. One such class of devices is the Maxon high efficiency motors. They get their name because they can provide efficiencies typically better than 90%.

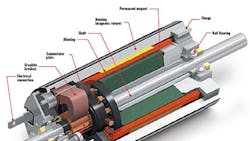

The key to high-efficiency for these devices lies in the fact they have a coreless (sometimes called ironless) design. Coreless design means there are no slotted laminations. Such devices can be considered specialized versions of brush or brushless dc motors. Brushed motors are referred to as “coreless” designs, and brushless versions as “slotless.”

On one such brush motor design from Maxon, the rotor winding surrounds the stator magnets. The rotor fits inside a magnetically-soft cylinder that doubles as the housing for the motor and provides a return path for the flux. This sort of architecture eliminates the largest concentration of stray losses associated with motors, the losses associated with leakage in the laminate core. Specifically, iron losses in the iron core are a result of remagnetization and induced eddy currents. Thus iron losses arise only when the magnetic flux changes.

The benefits of the ironless winding scheme include rapid acceleration and no magnetic cogging. That is because the rotor is much lighter in weight (mass) than a conventional rotor formed from copper windings on steel laminations. The resulting mechanical time constant can be quite low. There is no cogging (vibration caused by attraction between the iron and the magnets) because there is no iron in the rotor.

Part of the efficiency, though, is dictated by the type of magnet used in the design. For example, motors using stronger magnets, such as NdFe, will be more efficient.

A point to note is that the slotless brushless versions of some coreless designs do have eddy current losses at high speeds, which may reduce the maximum continuous torque of the motor. As a result, these brushless coreless designs are only slightly more efficient than competing technologies.

Of course, the final efficiency of a motor doesn't mean much if it is driving an inefficient system. The efficiency of motors without a load can be read from manufacturer ratings based on standard formulas. To understand high efficiency motors you only need to know what makes them different.

Nevertheless, it is useful to look at the basic concept used for explaining motor efficiency, which says that efficiency is the ratio between the shaft output power and the electrical input power. Shaft output can be measured in horsepower or watts. We'll use watts for the purposes of this article. The formula most often used is

ηm = Pout /Pin

where ηm = motor efficiency, %; Pout = shaft power out, W; Pin = electric power to the motor, W.

Once you've used this formula to find efficiency — and it's not 100% — it's time to consider the losses that inside the motor. Motor efficiency drops based on several factors relating to how power is lost as current through the motor meets with a variety of resistances. These losses can include the wiring and its resistance, iron losses due to magnetic events, and thermal losses.

The electrical power that is lost in the primary rotor and in the secondary stator windings are called resistance losses (or copper losses, because they are based on the characteristics of the wire used including its diameter and length). Both primary and secondary resistance losses vary with the load in proportion to the current squared. For example:

Pcl = I2R

where Pcl = stator winding, copper loss, W; R = resistance, â¦; I = current, A.

Other losses include iron losses, as mentioned above. These are the result of the amount of magnetic energy dissipated when the motor's magnetic field is applied to the stator core. Other factors involved include mechanical losses, which involve the friction in the motor bearings and stray losses, which are basically any remaining losses left after the resistance, iron, and mechanical losses are calculated.

The largest culprit for stray losses are the result of harmonic energies that are generated when the motor operates under load. The load affects the shaft power output, so one must know something about the load to express the equations properly. But basically, these losses are dissipated as currents in the windings, harmonic flux components in the iron parts, and leakage in the laminate core.

More info www.maxonmotorusa.com