Embedded Applications Rely on Small-Density NOR Flash Memory

What you’ll learn:

- The persistent need for small-density memory in today’s market.

- Why embedded applications need small-density NOR flash memory.

- What are the best options for small-density NOR flash?

Companies that design embedded systems such as medical analysis systems, garage-door openers, electric drills, manufacturing line equipment, or similar products need a guaranteed supply of essential components for 20 years or even longer. By building the support chips that surround the microcontroller (MCU) in these systems, including analog and serial memory devices, an embedded chip supplier can guarantee that they will be available as long as the customer needs them or until they stop ordering them. For the important role they can play in a multitude of embedded control systems, small-density NOR flash memory devices deserve a closer look and consideration for new designs.

The Ongoing Need for Small-Density Memory

Small-density serial NOR flash memory ICs have more than sufficient capacity for the affordable development of everyday embedded MCU applications like home appliances, LED controllers, and industrial power supplies.

While many leading NOR flash suppliers are ending the production of small-density memory, declaring end of life (EOL) and forcing designers to use larger NOR devices, there’s a continuing need for small-density memory in today’s market. For example, a small system that only requires 8 Mbits of NOR flash programming code, but is built using a 128-Mbit NOR flash IC, creates inefficiencies in power consumption and overall system cost.

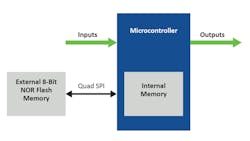

Microcontrollers are at the heart of embedded systems in ubiquitous items such as garage-door openers and power drills. In the systems approach, an MCU is supported in an application by several different IC technologies to deliver the functionality, performance, and cost required by a specific system. In addition to meeting other application requirements, the chips need to be small. The simplest systems just need a few additional components, including external memory, to provide unique functions (Fig. 1). These types of products/systems require memory but not a lot of it.

Options for Small-Density NOR Flash

While low-density NOR flash may not fit into the plans or strategy of large NOR flash suppliers, it’s an excellent fit into an embedded company’s product offerings and strategy for a systems approach. For example, a typical home could easily have several dozens of embedded systems with 8-, 16-, or even 32-bit MCUs. Most of these systems don’t require a large amount of code and external NOR flash could provide calibration data, calibration parameters, event logs, and more.

A multitude of MCUs come with built-in flash, but many situations will employ external NOR flash. Reflashing and programming before installing in the end system are just a few of the reasons. Common applications include embedded MCU-based systems that attach external NOR flash to hold sets of images for displays on small equipment screens, or microcontroller systems that attach external NOR for nonvolatile logging of measured data, changing system performance and task management.

Also, lower-gate-count application-specific integrated circuits (ASICs) such as field-programmable gate arrays (FPGAs) and complex programmable-logic devices (CPLDs) use small NOR flash for in-application programming, boot code and execute-in-place (XIP) operation.

In today’s extremely power-conscious designs, over-specifying NOR flash with perhaps 128 Mbits where only an 8-Mbit unit could easily do the job may result in several milliwatts of unnecessary power consumption. Developers can save power (and battery life) and reduce costs with high-quality memory devices in 2-, 4- and 8-Mbit densities.

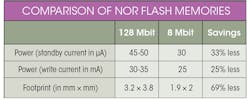

For smaller die, standby currents are lower, and there are several good reasons for using only the memory required for a specific design. For example, in a 3-V, 128-Mbit NOR flash, standby current (Isb) is 45 to 50 µA max and write current is 30 to 35 mA (max). In contrast, a 3-V, 8-Mbit NOR flash has an Isb = 30 µA max (1/3 less) and a write current of 25 mA max (1/4 less).

Read similarly to random-access memory, NOR flash memory is perfect for XIP applications offering low standby power consumption and directly accessible using a standard serial interface such as SPI.

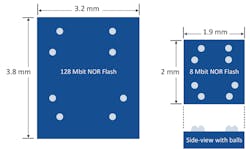

With their availability in 8-pin packages, such as an 8-lead SOIC and 8-contact WDFN (6 × 5 mm), small-density NOR flash memory devices are very board efficient as well. For high-volume applications with limited board space, such as an electric toothbrush, a wafer-level chip-scale package (WLCSP) provides considerable package space savings (almost 69%) (Fig. 2).

The table summarizes and compares the savings by using an 8-Mbit NOR instead of over-specifying a 128-Mbit NOR. If smaller 4- or 2-Mbit devices can be used, the power savings are even greater.

Knowing that these types of low-density flash will be available for future needs may change the design philosophy for some products. Rather than design around a product that’s much more than is required, specific applications can use just the amount of memory required to do the job.

Improved NOR Flash

With small-density NOR flash being an important part of an embedded-system supplier’s portfolio, product improvements are essential and inevitable. Recently introduced 8-, 4-, and 2-Mb NOR flash (SST26VF080A, SST26VF040A, SST26VF020A) provide examples of performance improvements.

According to Microchip, the SuperFlash technology in these NOR flash products provides the industry’s fastest erase times with block erase times 20X faster and full chip erase 1000X faster. This increases throughput and helps lower manufacturing costs with drop-in replacements for existing NOR flash designs.

For additional power savings, a 3-V, 128-Mbit NOR flash (without SuperFlash technology) has a max block erase time of 0.7 to 1 second. In contrast, a 3-V, 8-Mbit NOR flash (with SuperFlash technology) has block max erase time of 25 ms (30 times faster). In addition to the time savings, the erase/rewrite power difference is ~800 ms * 33 mA on every block erase for a rewrite cycle.

Furthermore, a serial quad I/O (SQI) interface with clock rates of up to 104 MHz provides excellent performance in less space while lowering total system costs.

Grant Hulse is Manager of Product Marketing for Microchip Technology’s Memory Product Division.

About the Author

Grant Hulse

Manager of Product Marketing, Memory Products Division, Microchip Technology

Grant Hulse is manager, product marketing, for Microchip Technology’s Memory Product Division, leading strategic marketing initiatives in the area of nonvolatile memory. This includes the company’s EEPROM, EERAM, flash, SRAM, and other products used in data-center and computing applications.

Prior to Microchip, Mr. Hulse managed memory marketing for Atmel Corp., which was acquired by Microchip in 2016. Earlier, he worked for several years as a senior marketing director at Cypress Semiconductor. Mr. Hulse held successive prior leadership roles in engineering, business development, and marketing at startup and mature semiconductor companies that include Simtek Corp., RF Magic, New Logic Technologies, AMI Semiconductor, and NEC Electronics in roles based in the U.S. and Japan.

He holds a Bachelor of Science in electrical engineering from Brigham Young University and a Master of Science in electrical engineering from Stanford University. He completed the NEC Electronics Executive MBA program and has published industry articles and white papers on a broad range of topics throughout his career.