How Linear Regulators, Voltage Supervisors, and LDOs Deliver Low Iq

This article is in the TechXchange: Why Low Iq is the Smart Thing to Do.

Members can download this article in PDF format.

What you'll learn:

- The importance of low Iq with linear regulators and LDOs.

- A look at low-Iq voltage supervisors in portable electronics.

- Battery-voltage supervisors in the IoT.

In my article “What is the Essence of Quiescent Current?,” I define quiescent as “a state or period of inactivity or dormancy.” In an electronic system, quiescent current is what flows through these systems while in standby mode with no load present or with a light load.

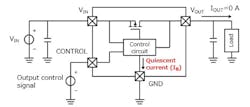

Quiescent current is generally defined as the current flowing from the GND terminal. Most datasheets will have a quiescent-current (Iq) value, when at a zero current load conditions, that’s at a specified input voltage (VIN), bias voltage (VBIAS), and temperature.

This article will delve into low Iq features for three key component groups in electronic design: linear regulators, low-dropout (LDO) regulators, and voltage supervisors.

Linear regulators must have an input voltage that’s a small amount higher than the desired output voltage. This “small amount” is called the dropout voltage. The definition of a LDO regulator is actually a DC linear voltage regulator that’s able to regulate its output voltage, most importantly when the power-supply voltage is quite close to that output voltage.

Linear Regulators

Linear voltage regulators need to possess a low Iq so that they will be able to operate the internal circuitry when the system goes to standby mode.1 When in the idle state, there will be little to no output load required. The quiescent current will typically dissipate in the form of heat while the overall system remains idle. However, the LDO discussed below will continue to draw a quiescent current for the preparation of a load.

Linear regulator efficiency is given as:

Eff = (VO × lO)/[(VI × lI) + (VI × lQ)] × 100%

Quiescent current can have a major effect on efficiency in areas such as power-sensitive applications.

Low-Dropout Regulators

LDO regulators manage power in a system by converting a higher voltage power supply to a lower, stable voltage level. Quiescent current (IQ or IB) is defined here as the current that’s consumed by the internal control circuitry of an LDO in its active state (Fig. 1).

LDOs with low Iq are quite suitable for battery-operated mobile applications. Another key application can be when LDOs are placed after a DC-DC converter serving as a post-regulator. LDOs can also be connected direct-to-battery to create a relatively noise-free voltage supply.

Voltage Supervisors

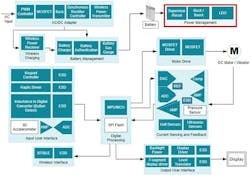

In battery-operated, portable electronic applications, a small board footprint, low Iq, and high accuracy are necessary for voltage supervisors.2,3,4,5 The block diagram of an electric toothbrush (Fig. 2) highlights a battery-operated voltage supervisor in the power-management block.

Portables like battery-operated toothbrushes and personal shavers are two excellent examples of those that need low Iq (to extend battery life), small size, and high accuracy in their design architecture.

The voltage-supervisor function will usually be a small three-pin (voltage, ground, and output) IC such as a SOT-23 package with a three-digit low Iq in the nanoamp range. In many cases, the SOT-23 package, measuring a mere 2.9 × 1.5 mm, may even be too large for a small-sized battery-operated product.

A much smaller option is a small outline package with no leads, known as an extra small outline, no-lead X2SON, which measures 1.0 × 1.0 mm. Another option is easier-to-mount SC-70 three-pin package with pins visible for easy probing. It measures 2.0 × 1.25 mm. Texas instruments’ TLV809E targeting handheld electronic applications, for instance, comes in an SC-70 package.

Ultra-Low-Power Voltage Supervisors

In extremely low power applications, many designers opt for voltage supervisors for very low power designs. An example would be in a maintenance-free wireless sensor node with smart dust powered by energy harvesting.

“Smart dust” biosensors are known as cubic-millimeter, wireless semiconducting sensor devices that monitor building environments as well as public spaces. These sensors also include functional, porous, micrometer-sized silicon particles that may be used to monitor very small-size environments.

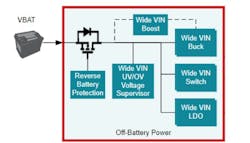

Furthermore, nanoamp voltage supervisors can be used in wide-voltage-input applications for automotive use. Automotive electronics designers who are performance-metric-oriented seek low Iq, better response time, as well as improved threshold accuracy.

Sensing 12- to 36-V voltage thresholds would most likely need the use of a voltage divider that could adjust the voltage threshold and not go beyond the absolute maximum on a sense/VDD pin. Unfortunately, using a voltage divider will usually lead to increased power losses, which may prove undesirable in many designs, such as those in automotive systems.

There are some voltage supervisor solutions in the market that have an Iq in the range of 350 nA which will enable additional headroom for current consumption. This feature is absolutely needed in automotive always-on systems with such standby current budgets in the region of 100 µA (Fig. 3).

Energy Harvesting for Battery-Voltage IoT Systems

Battery-voltage supervisors (BVSs) are quite capable of handling a large internal battery IR resistance. In this section, two low-power examples of these BVSs, fabricated in a 180-nm CMOS process, will be discussed.

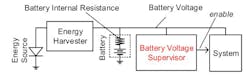

IoT system architectures will frequently include an energy harvester, which will derive energy from a source, such as a solar cell, and then transfer that energy to a battery (Fig. 4).6 The battery voltage (VBAT) will change over time depending on the quantity of the energy that’s harvested vs. the overall system energy that’s consumed.

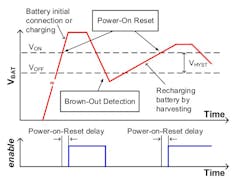

To prevent unpredictable circuit behavior along with permanent damage to the battery, a BVS must monitor VBAT and will only enable the system when the VBAT exceeds a given threshold (VON) (Fig. 5).

Designers can prevent any oscillation due to circuit noise and error if the conventional BVSs use two fixed threshold voltages along with a voltage difference of 1 to 10 mV. VOFF is the lower threshold voltage that will set the lowest VBAT at which the circuits will operate properly without damage to the battery.

The higher threshold voltage (VON) will provide hysteresis (VHYST = VON − VOFF), thus preventing the system from oscillating between the reset and operation modes. A conventional voltage regulator can’t function as an alternative to the BVS because it’s unable to prevent the battery from being discharged below the voltage that will cause permanent battery damage.

Read more articles in the TechXchange: Why Low Iq is the Smart Thing to Do.

References

1. “Understanding the Foundations of Quiescent Current in Linear Power Systems,” Texas Instruments.

2. “Ultralow Power Voltage Supervisor for Ambient Power-Driven Microcontroller Systems,” IEEE Transactions on Industrial Electronics, Vol. 66, No. 5, May 2019.

3. “A 0.75-5V, 15.8 nA with 1.8 μs Delay Supply Voltage Supervisor using Adaptively Biased Comparator and Sample & Hold Technique for IoT,” IEEE CICC 2021/Session 17: DC-DC Converters/Paper 17-7.

4. “Achieving Nano Amp IQ Voltage Supervision in Automotive, Wide-VIN Applications,” Texas Instruments, Application Report.

5. “Using low-Iq voltage supervisors to extend battery life in handheld electronics,” Texas Instruments.

6. “Battery Voltage Supervisors for Miniature IoT Systems,” IEEE Journal of Solid-State Circuits, Vol. 51, No. 11, November 2016.

About the Author

Steve Taranovich

Freelance Technical Writer, Phoenix Information Communication LLC

Steve is a contributing editor to Electronic Design.

Author of the non-fiction “Guardians of the Right Stuff,” a true story of the Apollo program as told by NASA and Grumman Corp. engineers, an astronaut, and technicians.

Experienced Editor-In-Chief of EETimes/Planet Analog and Senior Technical Editor at EDN running the Analog and Power Management Design Centers from 2012 to 2019.

A demonstrated history in electronic circuit design and applications for 40 years, and nine years of technical writing and editing in industry. Skilled in Analog Electronics, Space-related Electronics, Audio, RF & Communications, Power Management, Electrical Engineering, and Integrated Circuits (IC).

1972 to 1988 worked as a circuit design engineer in audio (8 years) and microwave (8 years). Then was Corporate Account Manager/applications engineer for Burr-Brown from 1988 to 2000 when TI purchased Burr-Brown. Worked for TI from 2000 to 2011.

Strong media and communication professional with a BEEE from NYU Engineering in 1972 and an MSEE from Polytechnic University in 1989. Senior Lifetime member of IEEE. Former IEEE Long Island, NY Director of Educational Activities. Eta Kappa Nu EE honor society member since 1970.