IGBTs Not Done Yet: Smart and High-Efficiency Options Enter the Fray

You almost have to feel some empathy for insulated-gate bipolar transistors (IGBTs). They have been the workhorse of many motor and power projects for decades and continue in that role. But now it seems that MOSFETs, whether basic silicon, silicon carbide (SiC), or gallium nitride (GaN), get all the attention and glory.

Though IGBTs still play major roles in power-switching designs, the obvious question is: “When do you use which class of device?” And it has the usual response of “It depends.” The answer is a function of the specific parameters of available devices as well as project priorities.

There are no hard-and-fast “choose one/the other” rules, but one general comparative overview provides insight and a starting point (Fig. 1).

Note that the demarcation lines aren’t “hard” borders but rather fuzzy, and they keep shifting as device processes and technology advances. (The references below offer some perspectives on the IGBT versus MOSFET landscape; note that some of them are somewhat self-serving and biased but still worth reading).

Intelligent IGBTs with BLDC Motor Drivers

Despite the lower profile of IGBTs, vendors are announcing new ones. Toshiba Electronics has introduced two IGBTs with included drivers for three-phase brushless DC (BLDC) motors in applications including fan motors, ventilation fans, air conditioners, air cleaners, and pumps.

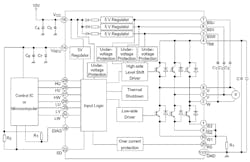

Each of these “intelligent power devices” (IPDs) incorporates a trio of 600-V-rated IGBTs along with matched high- and low-side gate drivers as a one-chip solution in a single compact package. The output DC current (IOUT) rating of the TPD4163F is 1 A while the TPD4164F is rated at 2 A.

The devices can be directly controlled from logic outputs of an MCU or motor controller, with a minimum number of discrete passive components (Fig. 2).

The TPD4163F and TPD4164F IGBTs have a saturation voltage (VCEsat) of 2.6 V and 3.0 V, respectively, while the diode forward voltages (VF) are 2.0 V and 2.5 V, respectively.

Both devices come in a miniature surface-mount HSSOP31 package, with dimensions of just 17.5 × 11.93 × 2.2mm. This reduces the PCB footprint by around 63% when compared with Toshiba’s existing DIP26-package products, and thus drastically cuts the space required for motor-drive circuit boards.

The devices are designed with the recognition that certain geographic regions will cause the power supply to be unstable, and in turn, the supply voltage may fluctuate significantly. To improve reliability, the supply voltage rating (VBB) has been increased from 500 to 600 V to allow for additional design margin.

In addition to the datasheets for the TPD4163F and TPD4164F, Toshiba provides documentation for a 120- to 340-V sensorless vector control BLDC motor demonstration circuit using the TPD4164F in conjunction with the company’s TMPM374FWUG MCU. The 130- × 85- × 53.4-mm board design (Fig. 3) is fully supported by a design guide, sample software, bill of materials (BOM), schematic diagram, PCB layer details, and more.

STMicro IGBTs for Induction Heating

Toshiba isn’t the only vendor announcing new IGBTs. STMicroelectronics released a new class of IGBTs with an increased breakdown-voltage capability of 1350 V and maximum operating temperature of 175°C. The STPOWER IH2 series IGBTs enable increased power-conversion efficiency in single-switch quasi-resonant converters over a wide 16- to 60-kHz switching-frequency range.

These IGBTs are well-suited for induction-heating applications, including domestic appliances such as kitchen hobs, inverter microwave ovens, and rice cookers. In a 2-kW application, ST maintains that they can reduce power dissipation by up to 11%.

The STGWA25IH135DF2 is a 25-A IGBT in a TO-247 long-leads package, while the otherwise similar STGWA35IH135DF2 is rated at 35 A (Fig. 4). The IGBTs feature low saturation voltage Vce(sat) of 1.7 V (typical), ensuring low dissipation when the device is turned on.

In addition, Vce(sat) has a positive temperature coefficient along with tight parameter distribution between devices, which helps simplify design and ease connecting multiple IGBTs in parallel to address higher-power applications. The freewheeling diode has low voltage drop and optimized turn-off energy that increases the efficiency of single-switch quasi-resonant converters operating at frequencies from 16 to 60 kHz.

Pricing starts from $1.39 for the STGWA25IH135DF2 and $1.69 for the STGWA35IH135DF2 (1,000-piece orders).

References

LinkedIn, “Power MOSFET VS IGBT: Which Is Better For Your Design?”

Electronic Design, “SiC and GaN vs. IGBTs: The Imminent Tug of War for Supremacy”

Rantle East Electronic Trading Co., Limited, “IGBT vs MOSFET: What’s The Difference?”

Arrow Electronics, “SiC MOSFET vs. Si IGBT: SiC MOSFET advantages”

Tutorials Point (India) Private Limited, “Difference between IGBT and MOSFET”

Electronics for U, “Difference Between IGBT and MOSFET”

Toshiba Electronic Devices and Storage, “What is the difference between MOSFETs and IGBTs?”

Wolfspeed, “Choosing the Best Option for your Design: The Advantages of Silicon Carbide MOSFETs over IGBTs”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.