Ultra-Compact, 1.2/2.3-kV Gate Drivers Reveal Important Green Power Industry Trends

What you’ll learn:

- How the new gate drivers meet the cost and performance requirements of grid-scale renewable generation and storage applications.

- PI’s devices provide a textbook example of how emerging products and technologies evolve as the markets they serve mature.

- A quick look back in time to see how the same process played out in the iconic Tesla Roadster.

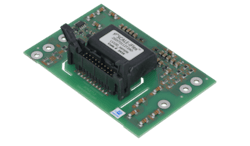

The new SCALE-iFlex XLT family of dual-channel “plug-and-play” gate drivers developed by Power Integrations (PI) tells us a lot about the technical issues and market demands driving the rapid maturation of green power products related to wind and solar generation, as well as the grid-scale energy-storage sectors (Fig. 1).

Surge in Demand for Inverter Electronics in Grid-Scale Energy-Storage Systems

In addition to their technical merits, these devices exemplify how the evolutionary forces shape products as a new application moves from its early adoption stage to a full-fledged player in a commodity-oriented high-volume market.

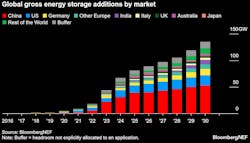

Besides being well-positioned to help support the steady growth of grid-scale solar systems, these products have emerged to address the sharp uptick in demand for the inverter electronics used in grid-scale energy-storage systems. This market is experiencing 20+% year-on-year growth and is expected to do so through 20301 (Fig. 2).

Advanced Gate-Driver Architecture for Renewable Energy

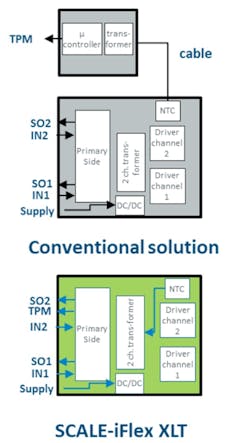

PI's new gate drivers are designed specifically to support the operation of single LV100 (Mitsubishi), XHP 2 (Infineon), HPnC (Fuji), and equivalent semiconductor modules used in wind, energy storage, and solar renewable-energy installations (Fig. 3). Their blocking voltage of up to 2300 V provides more than sufficient safety margin for the operating voltages commonly used in these applications.

The present family of modules is engineered to drive IGBTs. However, PI hinted that variants supporting wide-bandgap (WBG) devices may be anticipated for the not-too-distant future.

Equally significant is their compact single-board design that's compact enough to fit within the footprint of the target IGBT modules, enabling the drivers to be mounted on the module. As a result, they can be closely integrated with the devices they’re driving, allowing for active thermal management of systems that can be used to improve utilization, as well as reduce bill-of-materials (BOM) count.

Active Neutral Point Clamp and NTC

Another one of PI's most significant optimizations is the three-layer active neutral point clamp topology, which makes it possible to use less-expensive power devices with lower blocking points. It also leads to the production of smoother switching waveforms, significantly reducing the amount of filtering required while increasing overall system efficiency.

In addition, the drivers' compact form factor makes it easier to directly attach them to power bridge modules. This, combined with the devices' negative temperature coefficient (NTC) data—an isolated temperature measurement of the power module—allows for accurate thermal management of converter systems. As a result, system designers can optimize thermal design and obtain a 25% to 30% converter power increase from the same hardware.

Meanwhile, the isolated NTC readout also reduces hardware complexity, eliminating multiple cables, connectors, and additional isolation barrier crossing circuits (Fig. 4).

All of these features are made possible by the growing demand for devices optimized to meet the requirements of a rapidly growing market. When an application first emerges, designs are based on existing generic components, or those developed for other applications.

At this point, other external components must be used to incorporate any specialized functionality and protection features required by the new application. Moreover, the available packaging usually isn’t optimized to fit the mechanical, thermal, and manufacturing constraints that a mature product would need to address. This changes as demand provides the incentive to invest in the substantial R&D required to create application-optimized products (see below “Tesla: A Historical Perspective on Tech Evolution).

To summarize, Power Integrations has identified a significant trend in both grid-scale renewable-energy production and energy-storage systems. The rapidly declining cost of grid-scale storage systems, with an assist from PI’s gate drivers, will help make the adoption of renewable energy even more practical than ever. The SCALE-iFlex XLT gate drivers are available for sampling now.

Tesla: A Historical Perspective on Tech Evolution

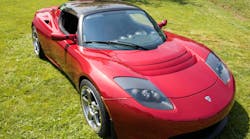

One of the most notable examples of the low levels of integration in early products I've ever seen was during a tour of the factory where the first Tesla Roadster was being built (Fig. 5). An electric drive system was being cobbled into a lightly modified Lotus Elise "roller" chassis.

At the time (2008), the agreement I’d made prevented me from describing the control and drive electronics boxes that were being shoehorned into every part of the vehicle's diminutive body. However, I can tell you in retrospect that the extensive use of OTC components made them much more complex and bulky than that for a product designed for high-volume production.

Every board I saw in the assembly area bristled with clusters of general-purpose DSPs, glue logic, and discrete power devices that would eventually need to give way to much higher levels of integration. Similarly, many assemblies were tied together with ribbon cables and other bulky interconnects.

Please note that this in no way takes away from the brilliant engineering that made the roadster like no other vehicle on Earth (except perhaps for Wrightspeed's X1 prototype). It simply illustrates the first stage of evolution that nearly every fledgling technology must undergo as it starts up the adoption curve. In fact, it's been fascinating to watch the Tesla team steadily optimize their designs from what I saw during that fateful visit as they continuously maximize value and performance.

Reference

1. Nelson Nsitem, “Global Energy Storage Market Records Biggest Jump Yet,” Bloomberg NEF, April 25, 2024.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.