Dissolvable Batteries, Recyclable PCBs — What’s Going on Here?

What you’ll learn:

- Many interesting research efforts are underway in less-known, less-glamorous areas that can address specific problems.

- How a dissolvable battery could facilitate the use of medical devices that need to be implanted.

- How recyclable, healable circuit boards may enhance component recovery, sustainability, and reuse.

Lots of advanced and innovative research is going on in so many areas — quantum computing, optoelectronics, terahertz waves, to cite just a few — that it’s easy to overlook some of the smaller, less glamorous, yet still interesting areas where there’s ongoing investigation. Even if these don’t lead to marketable or commercial success, they still show the range of small and large efforts that are ongoing. Further, you never know which ones will unexpectedly progress to the next level of viability or perhaps solve a specific niche problem.

We’ll look at two of these developments and while they’re unrelated, both are at the core of modern electronics: batteries and printed circuit boards (PCBs).

A Dissolvable Battery Using Probiotics

Researchers at Binghamton University (New York) have developed a “transient” biobattery powered by commercially available probiotics that dissolves harmlessly, releasing only beneficial microbes. This biobattery, which is fabricated on water-soluble or pH-responsive substrates, uses a 15-strain blend of probiotics (live microorganisms that offer health benefits when ingested but are otherwise harmless) to generate electricity across diverse electrode materials.

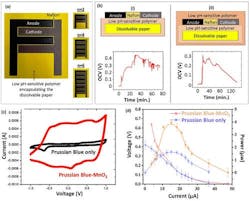

By manipulating device length or encapsulating it with pH-sensitive polymers, power delivery can be fine-tuned from four minutes up to over 100 minutes. A single module outputs 4 µW of power, 47 µA of current, and an open-circuit voltage of 0.65 V. To enable scalable and low-cost production, the device can be printed or pencil-drawn on dissolvable paper with varying lengths or numbers of serpentine electrodes within capillary microfluidic channels.

>>Check out this TechXchange for similar articles and videos

Note that the primary objective of these transient and bioresorbable electronics wasn’t the well-rehearsed claim reduction of e-waste. Instead, its fundamental purpose is to enable short-term, predefined operation, after which the battery safely disintegrates when no longer needed. This is a good fit for applications where retrieval is impractical or undesirable, such as temporary medical implants, environmental sensors, or disposable security devices

All components of the biobattery — including the substrate, printed wax boundaries and membranes, pencil-drawn electrodes, and Prussian Blue cathode — were designed to disintegrate in water as the substrate dissolved (Fig. 1).

The water-soluble paper is primarily derived from bio-based materials, such as wood pulp fibers combined with a natural cellulose component. Upon contact with water, the cellulose dissolves, causing the wood pulp fibers to disperse into microfibers. This process is facilitated by the hydrophilic nature of cellulose, which promotes interaction with water molecules and leads to the breakdown of the paper structure.

Construction of the battery is relatively straightforward and somewhat like a layered paint project; no semiconductor or advanced processes technology is needed (Fig. 2). Various formulations of the battery were tested, using resistive loads of 100, 10, and 1 kΩ.

The authors note that non-probiotic microbe-powered biobatteries have been successfully demonstrated as standalone power sources. However, these materials bring concerns about microbial cytotoxicity and associated health risks. They have largely restricted the devices to disposable and non-dissolvable applications.

This battery leverages the well-established safety and health benefits of these beneficial probiotic strains. It’s well-suited for transient and bioresorbable applications in both medical and environmentally sensitive settings.

The work is detailed in their paper “Dissolvable Probiotic-Powered Biobatteries: A Safe and Biocompatible Energy Solution for Transient Applications” published online by Wiley’s Small. There’s also a Supporting Information file posted with further details.

Recyclable, Healable Electronics

Whether using low-cost phenolic, ubiquitous FR4, or some more exotic material, printed circuit boards (PCBs) are literally the foundation of electronic circuits and products. But trying to recycle the boards, and perhaps even their board-mounted components for further recycling or reclamation of precious metals, is a challenge, as the inherent “rugged” nature of these boards isn’t amenable to such processing (have you ever tried to “decompose” an FR4 board?... good luck!)

Addressing this dilemma, a Virginia Polytechnic Institute and State University (better known as Virginia Tech) research team has developed a potential solution to the e-waste problem: a recyclable material that could make electronics easier to break down and reuse. They created a new class of circuit materials that are recyclable, electrically conductive, reconfigurable, and self-healing after damage. Yet they retain the strength and durability of traditional circuit board plastics — features rarely found together in a single material.

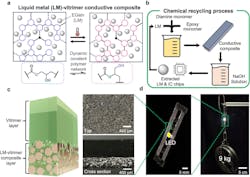

The new material starts with a vitrimer, a dynamic polymer that’s getting renewed attention as it can be reshaped and recycled. This versatile material is combined with droplets of liquid metal (LM) to create a LM-vitrimer microdroplet composite that carries the electric current, the way rigid metals do in a traditional circuit. The vitrimer circuit boards also can be deconstructed at their end-of-life using alkaline hydrolysis, enabling recovery of key components such as the liquid metal and LEDs.

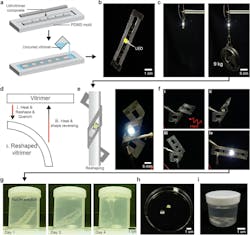

“Traditional circuit boards are made from permanent thermosets that are incredibly difficult to recycle,” said Josh Worch, assistant professor of chemistry. “Here, our dynamic composite material can be healed or reshaped if damaged by applying heat, and the electrical performance will not suffer. Modern circuit boards simply cannot do this.”

Unlike previous LM-incorporated composites which focused on permanent covalent networks or physically cross-linked networks for soft devices, their LM-vitrimer composites enable a unique combination of electrical conductivity, robust thermomechanical performance, high modulus, and recyclability without loss of electrical conductivity under high loads or deformation (Fig. 3).

Incorporation of LM into the vitrimer polymer matrix was accomplished by a shear mixing procedure. The LM-vitrimer conductive composite possesses qualities that are intrinsic to both thermoplastic and thermoset materials. One of the key advantages is its superior mechanical strength and rigidity owing to its highly cross-linked network. To demonstrate this, they fabricated a simple circuit with a single LED (Fig. 4).

They also investigated the degradability of the composite by chemical recycling. When the LM-vitrimer composite reaches end-of-life, valuable resources inside the composite must be retrieved. Because of the presence of ester bonds in the matrix, the composite could be degraded by base-catalyzed hydrolysis using an aqueous sodium-hydroxide solution. This enables the fabrication of fully vitrimer-based circuit boards consisting of sensors and indicator LEDs integrated with LM-vitrimer conductive wiring.

The composite also exhibits healing capabilities due to the dynamic ester bonds and reconfigurable LM droplet network. To demonstrate material healing, a razor blade was used to cut the surface of a composite. The damage was then repaired through a thermal trigger, enabled by the Joule heating capabilities of the composite. The composite heated and reconfigured to heal the cut in 10 minutes.

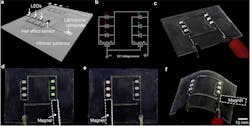

To demonstrate potential applications of the material for next-generation sustainable electronic devices, they created a fully vitrimer-based circuit board (Fig. 5). The circuit board is a transparent vitrimer sheet with dynamic ester bonds. The circuit layer is a screen-printed LM-vitrimer composite that integrates two sets of LEDs and Hall-effect sensors in parallel.

For the full story, their work is detailed in the posted paper “Liquid Metal-Vitrimer Conductive Composite for Recyclable and Resilient Electronics” in Wiley’s Advanced Materials. The posting also includes a link to a Supporting Information file as well as four short videos.

References

Wikipedia, “Prussian blue”

Jackson’s Art Supplies, “The History of Prussian Blue (and why you won’t find it in most acrylic ranges)”

American Chemical Society (ACS), “Prussian blue”

Materials Today, “Vitrimers: Current research trends and their emerging applications”

ATSP Innovations, “Vitrimers: The thermosets that process like thermoplastics”

>>Check out this TechXchange for similar articles and videos

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.