Innovative Thermal Wicking Material Speeds Evaporative Cooling

What you'll learn:

- The apparently insatiable heat-removing demands of modern processors and other components.

- Why evaporative cooling is an attractive heat-removal option, but it has present-day limitations.

- How a new material greatly enhances the heat flow of evaporative cooling implementations.

When it comes to getting heat away from highly localized hot spots such as processors, designers have several passive options including heat pipes, vapor chambers (siblings of heat pipes, but with important differences), heatsinks, thermal jumpers, heat spreaders, and evaporative cooling.

Of course, getting the heat away is only part of the overall challenge, as “away” means you still have the heat problem — it’s just further from where it might do immediate damage. Passive methods to get transport heat away are attractive because they can squeeze into a tight space around the offending component and are highly reliable.

Now, researchers at the University of California San Diego have developed a new cooling material that could significantly improve the energy efficiency of passive evaporative cooling.

New Material Leads to Higher-Efficiency Evaporative Cooling

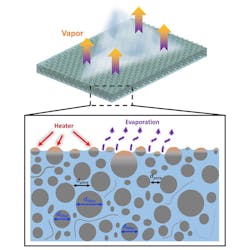

There’s nothing new in the principles of this cooling technique. It’s used in living organisms, has been intuitively understood and employed for millennia, and scientifically understood and modeled at both the macro- and micro-level since the 1800s; even Albert Einstein contributed several fundamental papers on the topic (Fig. 1). It’s now widely used in cooling systems as their sole cooling mode or as a part of the larger system, such as air conditioners and coolers.

(Note that despite the implications of its proponents, this cooling technique doesn’t reduce overall cooling needs. Instead, it improves the dispersion of the heat load from the source.)

Why the need for better cooling? It’s not news that today’s AI-centric processors run very hot. The maximum heat flux from advanced CPU and GPU chips today is well above 50 W/cm. For example, NVIDIA’s Hopper has a thermal design power (TDP) of 700 W on an 814-mm2 chip (86 W/cm heat flux) for AI applications.

AI isn’t alone in the need for drastic local cooling, as many other sources are running at over 100 W/cm. For example, there are high-power LED chips at 100 W/cm, high-power RF devices pushing over 1 kW/cm at die level, gallium-nitride (GaN) high electron mobility transistors (HEMTs) at over 1 MW/cm over each gate area, and pump lasers with 10 MW/cm facet optical-power density.

>>Check out this TechXchange for similarly themed articles and videos

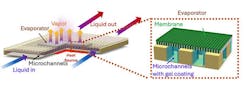

The UCSD technology features a specially engineered fiber membrane that passively removes heat through evaporation. It uses a low-cost fiber membrane with a network of tiny, interconnected pores that draw cooling liquid across its surface using capillary action.

As the liquid evaporates, it efficiently removes heat from the electronics underneath, and with no extra energy required. The membrane sits on top of microchannels above the electronics, pulling in liquid that flows through the channels and efficiently dissipating heat (Fig. 2).

Many applications already rely on internal or external evaporation for cooling. Some smartphones, including units from Samsung and Apple, use it in vapor-chamber cooling, a sealed-enclosure implementation of evaporative cooling.

Apple even touts its use in a breathless, literally fast-moving, one-minute ad that mentions it and puts up text to tell the audience a brief factoid: Its models 17 and 17 Pro smartphones use “vapor cooling” to enable highest-speed operation while keeping cool.

The large latent heat of liquid-vapor phase change enables efficient heat removal compared with single-phase cooling systems while offering better stability, no hysteresis, and reduced or even negligible pumping power requirements when leveraging passive capillary-driven flow. Unlike boiling, evaporation-based systems provide a more controlled and efficient heat-transfer mechanism, particularly for high-power applications.

What’s Actually Going On?

This thin-film evaporation is most effective in the region where the three phases — solid (heated surface), liquid, and vapor — converge. This region is typically less than 1 μm in thickness, balancing low thermal resistance in the liquid with adequate adhesive force to allow for efficient evaporation of liquid molecules.

The length of this region, however, is extremely small, on the order of 100 nm, and represents only a fraction of the entire meniscus. As a result, achieving high-flux evaporation relies on porous structures that provide a significantly larger surface area to enhance the overall evaporating area.

At least two mechanisms lead to the theoretical limit of capillary-driven evaporation heat flux from a nanoporous membrane made of individual nanopores: the kinetic limit and the capillary limit. The kinetic limit corresponds to the maximum vapor flux leaving the evaporating meniscus within the pores. It’s primarily governed by the rate at which liquid molecules escape from the liquid-vapor interface, approximated by the speed of sound and the effective area of thin-film evaporation meniscus that’s amplified by porous structures.

The capillary limit corresponds to the maximum liquid mass flux, dictated by the balance between viscous drag and the capillary driving force within the nanopores. It’s governed by liquid transport through the porous structure and the latent heat of vaporization. The theoretical critical heat flux (CHF) is determined by the lower of these two limits.

Previous theoretical and numerical studies have shown that these limits can exceed 5 kW/cm in nanoporous membranes with average pore sizes in the range of hundreds of nanometers. At these pore sizes, the capillary pressure can reach values greater than 100 kPa, providing the necessary driving force for efficient liquid transport and high evaporation rates.

However, effectively applying evaporative cooling to high-power electronics has impediments. Previous attempts using porous membranes, with their high surface areas that are well-suited for evaporation, have been unsuccessful because their pores were either too small that they would clog or too large that they would trigger unwanted boiling.

UCSD’s New Material Approach

After analyzing the likely reason for less-than-theoretical performance of existing membranes, the researchers developed porous fiber membranes with interconnected pores.

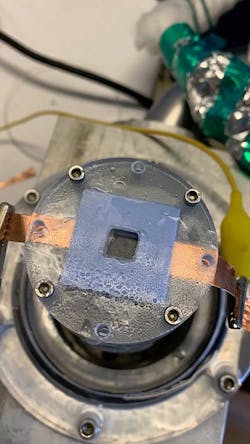

The glass-fiber membranes have mean hydraulic-pore sizes ranging from 3.2 to 11.4 μm, and they feature interconnected pores that facilitate fluid (liquid and vapor) transport to all areas within the structure. If a particular pathway becomes blocked due to contaminants or defects, the fluid can reroute through alternative pathways, ensuring that a few clogged channels don’t lead to in-use CHF degradation.

This design achieves efficient evaporation without those downsides. It demonstrates an efficient evaporator using a fiber membrane with 3D-interconnected pores, designed to address the clogging and local hotspot issues inherent to membranes with isolated pores.

The design achieved a record-high CHF exceeding 800 W/cm2 across a 0.5 cm² heating area (Fig. 3), representing the highest performance among capillary-driven evaporators of similar size.

These membranes also demonstrated long-term stability, sustaining continuous thin-film evaporation for over two hours at high heat flux. The superior liquid-spreading capability of the fiber membranes was further confirmed through high-speed imaging, revealing a clear correlation between the lateral and vertical liquid-spreading speeds and the achieved CHF values.

Beyond their impressive thermal performance, the researchers maintain that these fiber membranes are cost-effective, scalable for manufacturing, and exhibit mechanical flexibility and strength, as demonstrated by mechanical characterization.

Their work is detailed in the paper “High-flux and stable thin-film evaporation from fiber membranes with interconnected pores” published in Joule. It includes full analysis, fabrication details, shortcomings of alternative methods and materials, test configurations, graphs and tables of results across different scenarios, and more.

>>Check out this TechXchange for similarly themed articles and videos

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.