DC-Link Caps Promise 200,000-Hour Lifetime at 105°C

What you’ll learn:

- TDK’s ModCap UHP capacitors feature 200,000-hour lifetimes at 105°C and voltage ratings between 900 and 2,000 V.

- The high operating temperature solves the weakest link in wide-bandgap (WBG)-based converter and inverter designs for automotive, industrial, renewable energy and data center designs.

Power electronics engineers face a familiar challenge: The latest semiconductor technologies deliver smaller, more efficient converters with higher power output, yet at the same time, every other component in the system must keep pace.

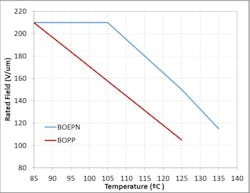

Wide-bandgap (WBG) semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) are driving this shift. Their faster switching speeds, lower losses, and higher junction-temperature capability enable more compact converter layouts that can operate at elevated temperatures. Capacitors must evolve to match these demands (Fig. 1).

Modern DC-link capacitors need to handle higher electric fields and larger current densities in smaller packages. They require extremely low equivalent series inductance (ESL) for fast transient response and a low, frequency-stable equivalent series resistance (ESR) to minimize losses at high switching frequencies.

Internal capacitor design matters as well. Parasitic effects like skin effect, internal resonances, and non-uniform current distribution can increase ESR and reduce efficiency.

Thermal management has become equally critical. Engineers often mount capacitors close to power semiconductors to minimize loop inductance, exposing them to conducted heat from power modules. Combined with less aggressive cooling systems and higher semiconductor junction temperatures, capacitors face increased thermal stress. They must operate reliably at higher temperatures and current densities without sacrificing lifetime.

This article explains how TDK tackled these challenges by developing a novel high-temperature dielectric film and integrating it into the ModCap UHP series, a new generation of modular high-power DC-link capacitors.

A New Polymer Engineered for Higher Temperatures

TDK has worked with industry partners for years to develop a dielectric film material capable of handling higher operating temperatures in metallized film capacitors. Building on earlier work with polypropylene–cyclic olefin copolymer (PP-COC) blends, Borealis, and TOPAS Advanced Polymers recently introduced Stelora EPN (Ethylene-Propylene-Norbornene).

EPN blends two materials:

- Polypropylene (PP): a proven, easy-to-process dielectric

- Cyclic olefin copolymer (COC): a dielectric with superior temperature capability

COC alone can’t be stretched into a film. When blended with PP, though, the result is a material that processes like standard PP while retaining COC's high-temperature strength.

Biaxially oriented EPN (BOEPN) films deliver excellent performance in practice. At moderate temperatures, they self-heal as effectively as standard biaxially oriented polypropylene (BOPP), matching its dielectric strength and capacitance density.

>>Check out this TechXchange for similar capacitor-related articles and videos

At elevated temperatures, BOEPN clearly outperforms BOPP. Even during Accelerated Life Tests (ALT), BOEPN films maintain good self-healing capability, lower leakage current, and higher breakdown strength. This combination prevents thermal runaway under DC voltage stress and ensures robust operation at elevated temperatures.

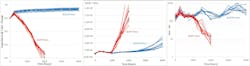

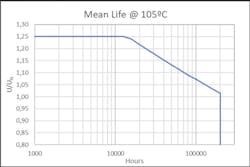

When used in metallized film capacitors, BOEPN delivers significantly better aging behavior and reliability than BOPP (Fig. 2).

Tests at +125°C show that BOPP-based capacitors age faster. They lose capacitance, show higher losses (tan δ), and exhibit decreased insulation resistance. This, in turn, means higher leakage current and increased risk of thermal failure. BOEPN-based capacitors, by contrast, show only a slow increase in tan δ, primarily from mild electrode oxidation.

Multiple endurance tests confirm this advantage. As Figure 2 summarizes, capacitors using BOEPN withstand higher electric fields above +85°C, enabling higher capacitance density without derating or a shortened lifetime. With optimized capacitor design and BOEPN integration into ModCap technology, the rated electric field can be pushed even further (Fig. 3) — delivering higher power density and thermal stability for next-generation converters.

ModCap UHP: Built for Extreme Conditions

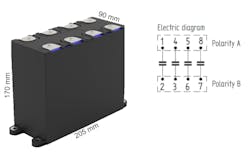

The ModCap HF series (B25647) with BOPP dielectric film has set the benchmark for DC-link capacitors used with advanced semiconductors. Building on this platform, TDK now offers the ModCap UHP series (B25648) with the new BOEPN dielectric film. This material enables operation at higher temperatures and current densities without derating, while maintaining the same mechanical design.

ModCap UHP targets demanding applications where power density, cooling constraints, and temperature push ModCap HF to its limits or even beyond. Typical applications include energy storage systems (ESS), central solar inverters, electrolyzers, high-power DC-DC converters, and auxiliary drives using SiC semiconductors.

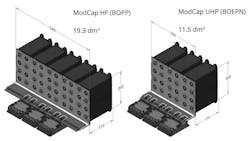

ModCap HF and UHP share the same modular concept, terminal layout, and external dimensions, ensuring mechanical and electromagnetic compatibility (Fig. 4).

Both feature extremely low inductance (ESL ≈ 8 nH) for fast transient handling, low ESR across a wide frequency range, and ISCC-certified bio-circular polypropylene. They offer identical capacitance values, high voltage strength, and a 200,000-hour lifetime at rated voltage and temperature.

ModCap UHP goes further:

- Up to +21% higher current density, enabling up to +45% higher converter power density in the same footprint.

- Rated operating temperature increased from +80 to +105°C without voltage or lifetime derating.

This makes ModCap UHP the right choice when converters must deliver more power under demanding thermal conditions, whether due to softer cooling systems or heat transfer from nearby semiconductors.

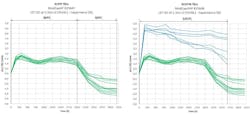

Testing beyond IEC 61071:2017 and IEC 61881-1:2010 confirms that ModCap UHP maintains aging behavior at +105°C comparable to ModCap HF at +80°C, demonstrating excellent stability and robustness under elevated-temperature operation (Figs. 5 and 6).

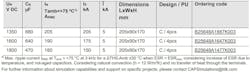

ModCap UHP comes in rated voltages from 1,350 to 1,800 V; Table 1 shows the main electrical parameters. Voltage extensions ranging from 900 to 2,000 V are under development.

Real-World Comparison: ModCap HF vs. ModCap UHP

To verify the practical advantages of switching from BOPP (ModCap HF) to BOEPN (ModCap UHP), TDK conducted a detailed case study on a high-current DC-link application. The goal was to assess how the +25°C higher rated temperature and +21% higher current density translate into actual design benefits — performance, volume, and lifetime.

The analyzed converter represents a typical high-power application:

- DC-link voltage: 1,600 V

- Total capacitance: ≥1,850 µF

- RMS current: 570 A

- Ambient temperature: +75°C

- Temperature at power module terminals: +95°C

- DC-link lifetime: ≥200,000 hr

Two DC-link configurations were evaluated: one using ModCap HF capacitors (BOPP dielectric) and one using ModCap UHP capacitors (BOEPN dielectric).

ModCap HF Solution

According to the ModCap HF datasheet,8 a suitable starting point is the B25647A1647K003 (1,600 V/640 µF/160 A). Three capacitors in parallel meet the capacitance requirement (≥1,850 µF), but deliver only 480 A (3 × 160 A), which is below the required 570 A. At least four units in parallel are needed to satisfy both current and capacitance demands.

Since this configuration is current-limited rather than capacitance-limited, a higher-voltage variant — B25647A11477K003 (1,800 V/470 µF/150 A) — provides a more robust lifetime margin. The resulting DC-link has a total volume of 15,400 cm3.

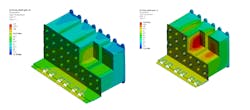

Finite-element-method (FEM) simulations assessed thermal behavior and expected lifetime. These include thermal boundary conditions (ambient temperature, cooling, heat transferred from power modules), the complete current amplitude spectrum over frequency, and electromagnetic effects on internal capacitor construction.

FEM results showed a maximum internal capacitor temperature of +96°C, caused by self-heating and heat conduction from power-module terminals (Fig. 7). Since this exceeds ModCap HF's +80°C rating, lifetime falls below 200,000 hours, violating the design target.

Maintaining lifetime and thermal margins requires five units in parallel, providing:

- DC-link voltage: 1,800 V > 1,600 V

- Capacitance: 2,350 µF > 1,850 µF

- RMS current: 750 A > 570 A

- DC-link volume: 19,300 cm3

While technically feasible, this solution significantly increases both size and cost.

ModCap UHP Solution

For the same 1,600-V system, the equivalent ModCap UHP capacitor is B25648A1647K003 (1,600 V/640 µF /190 A).7 This type offers identical voltage, capacitance, and outer dimensions to its ModCap HF counterpart, but it features 19% higher rated current and a 25K higher rated temperature (+105°C vs. +80°C).

Three capacitors in parallel fulfill all application requirements:

- DC-link voltage: 1,600 V = 1,600 V

- Capacitance: 1,880 µF > 1,850 µF

- RMS current: 570 A = 570 A

- DC-link volume: 11,500 cm3

Total DC-link volume drops by 40% compared to the ModCap HF design.

Thermal FEM simulations under identical boundary conditions revealed a maximum internal temperature of +104.8°C — just below the +105°C rated limit. The ModCap UHP design achieves full lifetime without derating: 200,000 hours even under elevated thermal stress.

Summary and Key Takeaways

For the high-current-density DC-link studied, only three BOEPN-based capacitors are required instead of five BOPP-based units. This reduction comes from higher current and power density, combined with the increased rated temperature of the ModCap UHP series.

As Table 2 and Figure 8 summarize, the ModCap UHP solution achieves:

- 40% lower DC-link volume, enabled by 19% higher current density and 25°C higher rated temperature.

- 25% lower capacitor cost, excluding additional savings from a smaller external busbar.

In high-power-density designs like the application analyzed here, the critical DC-link parameters are current density, thermal management, and lifetime. ModCap UHP delivers an optimized balance of those, providing a space-efficient solution for next-generation power converters based on advanced semiconductor technologies.

References

1. M. Gómez, "Innovative film capacitor technologies for wide band-gap semiconductors," IEEE PSMA Capacitor Committee Workshop 2020.

2. F. Rodríguez, "High Temperature Capacitors for Medium Voltage Applications with New WBG Semiconductors," ECPE Hybrid Workshop, Medium Voltage Power Electronics, Freiburg, Germany, 2025.

3. C. Alba, D. Peláez, and L. Cabo, "High-Temperature Metallized Polymer Film Capacitors Based on Blends of Polypropylene and Cyclic Olefin Copolymers," 2020 IEEE 3rd International Conference on Dielectrics (ICD), Valencia, Spain, 2020, pp. 669-672, doi: 10.1109/ICD46958.2020.9342006.

4. U. Wahner and C. Alba, "Polymers in Film Capacitors - The Next Generation Material is available!," PCIM Europe 2023; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 2023, pp. 1-8, doi: 10.30420/566091018.

5. IEC 61071:2017 Capacitors for power electronics.

6. IEC 61881-1:2010 Railway applications - Rolling stock equipment - Capacitors for power electronics - Part 1: Paper/plastic film capacitors.

7. ModCap UHP Datasheet, 2025.

8. ModCap HF Datasheet, 2025.

>>Check out this TechXchange for similar capacitor-related articles and videos

About the Author

Fernando Rodríguez

Applications & Modeling Group Director, TDK Electronics

Fernando Rodríguez received an M.Sc. degree in electronics from the University of the Basque Country, Spain, in 1999. Since 2001, he has been working with TDK Electronics (formerly EPCOS). He has more than 20 years of experience in FILM capacitor design and development for power electronic applications: HVDC systems, traction, automotive, and renewable-energy converters. His responsibilities are Applications, FEA Simulations, and Advanced Development. His research interest includes advanced capacitor development for WBG semiconductor technologies (GaN and SiC).

Manuel Gomez

R&D Project Manager, TDK Electronics

Manuel Gomez has more than 11 years of experience in high-power capacitors at TDK Electronics Components S.A.U. in Málaga, Spain, in the CAP division, focused on metallized film capacitors. Since 2013, he has served as Field Application Engineer and since 2017, Product Development Engineer. Involved in the development of high-frequency, high-temperature, and high-current film capacitors, including new technologies patented.

He was an industrial engineer at the University of Malaga, Spain (2013), Electrical Engineering Department, thanks to a scholarship, studying real-time control of multiphase induction motors. Graduated Certificate in Power Electronics at the University of Colorado Boulder, USA (2024).