This Week in PowerBites: 1 Tutorial, 2 Conferences, and Lots of LEDs

This article is part of the Power Management Series: This Week in PowerBites

CALL FOR PAPERS: Show off Your Power Prowess at PowerUP Virtual Expo 2021

The PowerUP Expo is welcoming potential presenters to submit papers for their three-day virtual conference and exhibition, focused on the frontiers of power technology. This year's program includes topic-specific session keynotes, panel discussions, technical presentations, and tutorials about major technical trends, market requirements, and new applications areas.

The event has a special emphasis on the role of power electronics in the "greening" of various markets such as automotive, industrial, and consumer. Many conference sessions will look at how power devices are being used to improve system performance in energy-saving applications, as well as in all high-voltage industrial applications. Others will explore the power-related enabling technologies being leveraged to provide a wide range of new functionality that enhances vehicle and smart-grid performance, safety, and functionality.

Parallel to the Conference will be an Exhibition featuring virtual booths from leading power electronics companies. A Live Chat tool enables visitors to directly contact booth personnel.

The conference agenda and details on how to submit a proposal for a paper presentation at PowerUP are available at this link.

Integrated Automotive LED Driver Simplifies Innovative Lighting Designs

With STMicroelectronics’ ALED6000 single-chip automotive LED driver that integrates a dc-dc converter and other features, designers can speed up development of application-specific, low-BOM (bill of materials) lighting designs that maintain a constant lighting intensity across a wide range of supply voltages. Suitable for exterior lighting such as daytime running lights, headlights, rear lights, stop lights, and turn signals, as well as interior lighting, the ALED6000 drives a single string of LEDs at up to 3 A and has an input-voltage range of 4.5 to 61 V.

The ALED6000 implements digital dimming and includes a dedicated pin to apply the pulse-width-modulation (PWM) control signal. The device's Enable and Sync pins can be used to ensure low noise in multi-device applications. Output current—accurate to within 3.2%—is monitored efficiently with a sense resistor that has a typical voltage drop of 250 mV. The quiescent current is extremely low, at just 2.4mA in operation and 11 µA in shutdown. Also featuring a VBIAS auxiliary-input pin and pulse-skipping operation at light load, the ALED6000 ensures high efficiency across the load range.

The driver's on-chip converter can be used in buck, buck/boost, and floating-boost topologies, enabling it to power LED strings that require a voltage above or below the input voltage. In addition, the converter can operate in low-dropout mode with close to 100% duty cycle if the input voltage falls near or below the programmed output.

During overcurrent conditions, the ALED6000 invokes pulse-by-pulse protection to limit the output current. Also in the mix is programmable soft-start circuitry and thermal protection with auto-recovery. Both the output-current limit and converter switching frequency can be selected using external components. This allows the inductor to be optimized for high energy efficiency, fast dynamic response, small size, and low output ripple in conjunction with a low-ESR capacitor.

AEC-Q100 qualified, the ALED6000 automotive LED driver is in production now in the HTSSOP16 package, priced from $2.25 for orders of 1,000 pieces. Designers can jump-start their projects using the STEVAL-ILL089V1 evaluation kit. For additional information, go to www.st.com/buck-current-regulators.

Single-Stage, Constant-Voltage Flyback Controllers for Smart LED Drivers Up To 125 W

The ICL8800, ICL8810, and ICL8820 single-stage flyback LED controllers developed by Infineon Technologies make it easier to design products that address the growing market for cost-effective dimmable and intelligent MOSFET-based LED systems up to 125 W. Their ability to deliver constant output voltages, and other unique features, provide the necessary performance requirements for LED lighting applications, such as LED drivers and luminaires, smart lighting, and emergency luminaires. Additional applications include adapters and chargers, flat TVs, all-in-one PCs, and monitors.

All three variants offer benchmarked performance for power factor correction and total harmonic distortion at full-load and low-load conditions. They also support critical conduction mode (CCM) and quasi-resonant mode (QRM) with smart valley hopping to maximize efficiency and reduce EMI. While they’re optimized for use as secondary-side-regulated (SSR) constant-voltage (CV) output flyback controllers, they also can be used for primary-side regulation (PSR).

The ICL8800 offers an external startup circuit control signal for more flexibility and a comprehensive set of protection features, including a power limitation and secondary-side overvoltage protection. The result is a cost-optimized bottom-up platform that can implement a wide range of applications with a minimum of external components.

The ICL8810 is an advanced variant of the '8800 intended for smart-lighting applications. It adds an integrated burst mode that allows a very low standby power consumption of less than 100 mW and flicker-free deep dimming down to 0.1%.

The ICL8820 is the fully featured variant, additionally equipped with an integrated dc-input jitter function. The latter improves EMI performance and supports the fulfillment of EMI requirements in dc operation. The ICL8820 helps ease EMI certification in LED-driver design for emergency-lighting applications without additional circuitry, minimizing cost and effort.

Availability

The ICL8800, ICL8810 and ICL8820 single-stage flyback LED controller variants are available in PG-DSO-8 packages and can be ordered now. More information is available at www.infineon.com/icl88.

Automotive Backlight Driver Sustains Constant Brightness Under Cold-Crank Conditions

Maxim Integrated Products recently unveiled its four-channel, low-voltage MAX25512 automotive LED backlight driver with integrated boost converter. To lower BOM cost and board space requirements, the single-chip LED driver eliminates the need for an external MOSFET and current-sense resistor. It integrates an I2C communication interface that can be used to adjust PWM channel settings, invoke diagnostics, and communicate its status. The highly integrated LED driver includes four 120-mA channels with 91% efficiency at 2.2-MHz operation.

The MAX25512 also is one of only a few integrated solutions that retain full, constant brightness of in-car displays with the extremely low supply voltages found in vehicles with weak or cold batteries—and the only one that can do this under severe cold-crank conditions down to 3-V input voltage. This is important because today’s automotive start-stop systems can make it difficult for a vehicle's power-delivery system to maintain constant display brightness during restart.

Offered in a small 24-pin, 4- × 4- × 0.75-mm quad flat no-lead (QFN) package, the MAX25512’s level of integration shrinks solution size by 30% by eliminating external components.

Availability and Pricing

The MAX25512 backlight LED driver and associated MAX25512EVKIT evaluation kit are available now from Maxim Integrated and authorized distributors; pricing is available upon request. For additional information on the MAX25512, visit https://bit.ly/MAX25512Products.

IEEE's Energy Conversion Conference Comes to Vancouver and Cyberspace

The Energy Conversion Conference and Expo (ECCE) is making its West Coast rotation to Vancouver, Canada, October 10-14, 2021. The flagship conference for the IEEE Industrial Application Society (IAS) and Power Electronics Society (PELS) is the world’s largest podium for presenting the latest power electronics, electric machines, and drives research, their applications, and engineering training.

With over 1,600 attendees (2019), multiple educational tutorials, technical sessions, industry panels, social events, and a public Exhibit Hall, the conference offers an ideal opportunity to meet with existing customers. Typically, half in attendance are international, which gives the exposure needed to forge new customer relationships.

ECCE's program includes a full schedule of technical sessions, tutorials, and a series of Special Sessions that address 25 of the most important technical issues emerging in the power-conversion industry. The Special Session topics include:

- Cybersecurity for Power Electronics

- Advances in SiC/GaN Grid Applications to Support EV and Renewable Energy

- Dynamic Modeling and Simulation for Reliable and Resilient Operation of Future Grids

- Additive Manufacturing for Electric Machines

- Power Electronic Technologies for Distributed Energy Resources

For those unable to travel to the event, the program will run in parallel using vFAIRS, a widely adopted virtual-event platform, providing participants with the closest “in-person” experience possible. The exhibition takes place over the first two days, at the height of conference attendance.

On day one, join industry leaders, entrepreneurs, and top researchers as they address attendees during the Plenary Sessions, followed by the Expo and Welcome Reception, which will offer complimentary food, beverage, and plenty of booth traffic. Visit www.ieee-ecce.org/2021 for more information and to secure your spot at the show.

Photovoltaic-Output Photocoupler Offers Increased Open Voltage for Isolated Solid-State Relays

The TLP3910 photovoltaic-output photocoupler from Toshiba Electronics Europe is suitable for driving the gates of high-voltage power MOSFETs used to develop a galvanically isolated solid-state-relay (SSR) function. Housed in a thin SO6L package measuring just 3.84 × 10 × 2.1 mm, it integrates a photo-TRIAC, a phototransistor, or a photothyristor.

The device is typically used for applications that require ON/OFF control of large electrical currents in industrial equipment such as I/O relay outputs in PLCs, inrush current protection in power supplies, and battery voltage monitoring in battery-management systems (BMS), as well as switching the power and signal lines in instrumentation applications.

The new TLP3910 has a minimum open voltage (VOC) of 14 V, enabling a single device to drive the gate of most high-voltage power MOSFETs. Until now, driving power MOSFETs with a gate voltage of 10 V or higher would require connecting two photocouplers, such as Toshiba’s TLP3906, in series due to their low open voltage (typically around 7 V). As a result, many high-power designs can take advantage of improved reliability, less PCB space, and lower BOM cost.

The TLP3910 also incorporates an improved discharge circuit with a typical turn-off time (tOFF) of 0.1 ms, about one-third that of the TLP3906 and about one-thirtieth that of the TLP191B. The new photocoupler also has a faster typical turn-on time (tON) of 0.3 ms. The TLP3910 is Toshiba’s first photovoltaic coupler to feature a minimum isolation voltage (BVS) of 5000 V rms while maintaining the excellent performance of the current products (TLP191B and TLP3906). This, along with the creepage distance of 8 mm and relevant UL/cUL approvals, enables use in industrial equipment driven by 400-V ac systems and other applications where electrical safety is paramount.

The high-temperature operation (TOPR) range of −40 to +125°C ensures that the TLP3910 is suited to a wide range of rugged applications. The TLP3910 is currently in volume production. For more information, visit https://toshiba.semicon-storage.com/eu/semiconductor/product/optoelectronics/detail.TLP3910.html.

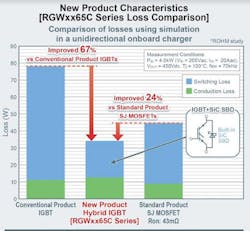

Hybrid IGBTs Boost Efficiency and Performance in xEVs, Chargers, and PV Power Systems

Rohm's RGWxx65C series of IGBTs (RGW60TS65CHR, RGW80TS65CHR, RGW00TS65CHR) enjoy dramatically improved efficiency thanks to a co-packaged low-loss SiC Schottky barrier diode that's used in the device's feedback block. By functioning as a freewheeling diode that consumes virtually no recovery energy, it minimizes the devices' diode switching losses. In addition, since the recovery current doesn’t have to be handled by the IGBT in turn-on mode, it also significantly lowers turn-on loss.

Together those features reduce power losses in vehicle chargers and other high-power applications by up to 67% compared to conventional IGBTs, and up to 24% compared with superjunction MOSFETs (SJ MOSFETs). The devices' high efficiency and integration enable them to deliver good cost performance while contributing to lower power consumption in automotive and industrial systems.

Applications include automotive chargers (on-board chargers), vehicle dc-dc converters, solar power inverters (power conditioners), and uninterruptible power supplies (UPS).

A broad range of design support material is available on Rohm’s website, including simulation (Spice) models and application notes on drive circuit design. Click here to access the company’s design support information.

Availability

The RGWxx65C series of IGBTs is sampling now, with mass production anticipated for December 2021. In addition to these novel hybrid IGBTs, Rohm also offers products utilizing silicon fast recovery diodes (FRDs) as the freewheeling diode, as well as products without a freewheeling diode.

Integrated Power Disconnect Solution Paves the Way to Faster, Safer DC Fast Charging

A unique disconnect solution for EV chargers developed by Sensata Technologies offers safer, more effective system protection and faster, easier installation than traditional solutions based on conventional contactors and thermal fuses. Key to the new power contactor module is the integration of advanced contactors and fuses.

This integrated solution was created to help EV charging systems safely deliver the faster charging times demanded by consumers, which may operate at up to 1,000 V and up to 350 kW. In addition to the ability to reliably break connections at these higher voltages and currents, these contactors must be able to provide safe circuit continuity in the event of a hazardous short-circuit event. In addition to meeting these requirements, Sensata’s GigaFuse products offer a smaller, more reliable solution than fuses that are required to be used in tandem for these applications.

Sensata’s packaged power disconnect module includes high-voltage contactors and GigaFuses harnessed to a mounting plate that reduces risk of damage and increases thermal performance. As a result, the module offers several advantages over a conventional dc thermal fuse, including:

- Response to overload is 3 ms or less; faster than a conventional dc thermal fuse.

- Opens the circuit closer to normal operating conditions without "nuisance tripping."

- A unique electromechanical triggering mechanism that pairs more easily with the contactor.

- Lower thermal resistance; typically, 0.15 mΩ, allowing it to run cooler for less thermal aging.

To learn more, go to www2.sensata.com/dcfc-solutions. Also, a white paper titled "GigaFuse Maximizes Safety in Advanced Battery Systems" is available here.

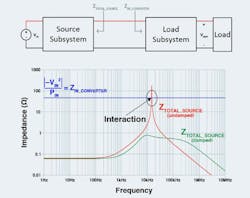

Design Tutorial: Stability Analysis and Decoupling for Modular DC‑DC Systems

Vicor's tutorial series "How to Design Modular DC‑DC Systems" is a pithy toolbox of well-written information-rich lessons that take you on deep dives into several less well-understood issues of power design. One of the more enlightening installments is a tutorial on stability analysis. As with the previous installments on modular design strategies and designing application-appropriate filtering, it introduces the principles of stability analysis and the math that underpins them, and then uses practical examples to demonstrate how they can be applied.

The tutorial begins by demonstrating how to separate the source and load elements so that their impedance can be analyzed and understood separately. This includes modeling the source and load's frequency-dependent finite impedances. This is followed by analyzing their combined stability to determine if a decoupling network is required and calculating the values of the necessary components. Click here to access this tutorial.

The other four tutorials in the series are:

- How to design modular DC‑DC systems, part 1: four stages of design

- How to design modular DC‑DC systems, part 2: filter design

- How to design modular DC‑DC systems, part 4: safety protection systems

- How to design modular DC‑DC systems, part 5: load considerations

Read more from the Power Management Series: This Week in PowerBites