How to Boost Power Density in Automotive Systems

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- What automotive systems and components help boost higher power density?

- A look at the GaN active-clamp phase-shifted full-bridge architecture.

- Cooling techniques that improve power density.

The latest design architectures, especially in automotive power electronic systems, are critical in the success of any new hybrid electric vehicle (HEV) or electric vehicle (EV). A high-voltage vehicle power network is necessary with voltages of 60 V and higher, along with a traditional 14-V power network.

High-voltage vehicle power network architectures contain an electrical energy-storage system and a traction drive inverter. Some HEV and EV system architectures also may contain high-voltage power electronic systems using dc-dc converters to power a low-voltage network. Examples include electrical air-conditioning compressors, cooling water pumps, oil pumps, traction bus voltage stabilization, and ac-dc converters for unidirectional or bidirectional interfaces to vehicle grids.

Let’s take a look at various power systems and components in the vehicle that contribute to an overall higher-power-density architecture.

V2X power

Vehicle system power-rail architectures for vehicle-to-everything (V2X) power (X stands for grid, home, or load) can have a 5-V bus generated, via the vehicle battery voltage, with the use of an off-battery buck converter. This type of design architecture is able to power all point-of-load (PoL) devices at a 2-MHz+ switching rate. Efficiencies of over 90% can be achieved. Such high switching rates, along with high efficiency, will greatly improve automobile power density.

GaN FETs in automotive

Using gallium-nitride (GaN) FETs in automotive power designs will enable high power density due to fast switching coupled with 600-V and higher capability in those designs. When an integrated driver is part of the solution, designers will be able to deliver as much as 2X power density, with 99+% efficiency, plus the bonus of reducing the size of power magnetics. Employing GaN-on-silicon substrates will enable a lower cost, along with a supply-chain advantage, as compared with silicon-carbide (SiC) devices.

Lightweight and compact power systems are key, especially in EV automotive systems. Engineers can now achieve extended battery range and higher system reliability—GaN enables this performance enhancement. On-board chargers and dc-dc converter sizes can be shrunk by as much as 50% with GaN vs. silicon or SiC solutions as well.

Again, here, high-frequency switching rates and high efficiency lead to excellent power density in the vehicle.

Automotive-grade current-sense resistors and shunts

Automotive power density also can be improved via the proper design usage of current-sense resistors. These resistors will have very low resistance values, good pulse performance, low temperature coefficient of resistance (TCR), low inductance, along with low noise.

A good current sense resistor will be able to provide exceptional pulse performance, while absorbing more electrical energy, before reaching the device temperature limit. The resistor element also must be quite robust to be able to handle higher temperatures. Laser trimming will help reduce harmonic distortion and circuit ringing, too.

When a material undergoes temperature variations, the dimensions either slightly increase or decrease as it expands or contracts. During duty-cycled or pulsed applications, power is switched off and on, which will cause repetitive heating or cooling expansion/contraction cycles.

Such thermal cycling may cause long-term reliability problems for solder joints of surface-mount components when there’s a large difference in the rates of geometric expansion/contraction. These different rates are usually known as coefficient of thermal emission (CTE) mismatch. Choosing a resistor with a CTE value, close to the CTE of a circuit board’s FR-4 material, will minimize this effect with better long-term solder-joint performance and lower failure rates.

Using automotive current-sense resistors can boost the power density in the automotive architecture, since the power rating increases as the resistor size decreases. In addition, designers should choose resistors that have multiple series, so that they can change series with the same size. In addition, designers can progress to higher power ratings. An all-metal construction is a positive feature in such resistors.

Designers, of course, will need to choose a resistor series that’s AEC-Q200-qualified for automotive use.

Automotive-grade high-power-density inductors for LED lighting

Advanced LED driver designs are being developed using electronic components that can deliver higher luminescence and improved energy efficiency, all at lower cost. Suppliers now provide higher-power LED headlight clusters that perform well at elevated current in a smaller footprint.

Today’s technologically advanced inductors used in LED lighting are able to handle higher temperatures (up to +155°C) and higher power density. Furthermore, footprint can be decreased by as much as half with the latest inductors. In the past, a popular inductor used to have a fairly large footprint of 12.5 × 12.5 mm on the printed circuit board. Today, manufacturers have decreased this size to 8 × 8.5 mm, maintaining the equivalent performance of several years ago. Pricing also has reached levels that are competitive in car manufacturing.

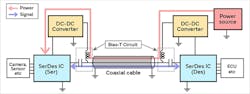

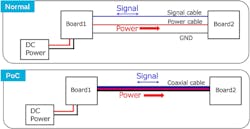

Automotive applications are becoming more sophisticated as they trend well beyond two or three LED drivers per automobile. Smaller inductors built with the latest advanced technology like thin-film metal lead to improved power density in the automobile. Bias-T and power-over-coaxial (PoC) circuits also use inductors that have high-impedance characteristics and lead to improved power density (Figs. 1 and 2).

High-Power-Density Design for EVs

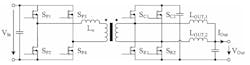

The GaN active-clamp phase-shifted full-bridge (PSFB) architecture has zero-voltage switching across the entire load and voltage range. It enables a 1.5-kW, 400- to 12-V dc-dc converter for automotive application with a wide voltage and power range. The small leakage inductance coupled with the ability to realize soft-switching, even under low load conditions, leads to a significant increase of the switching frequency up to 500 kHz.

This dc-dc converter architecture is able to transfer energy from a 400-V vehicle traction battery, in an electric or hybrid vehicle, to the 12-V electrical system. It also ensures galvanic isolation for safety.

The power density of the converter simplifies integration into an automotive vehicle. Magnetic components dominate the volume of the power electronics. Power density can be increased by raising the switching frequency. By using SiC or GaN transistors, very low conduction and low switching energies are achieved—far better than with silicon devices. The circuit topology can be seen in Figure 3.

Soft-switching, combined with GaN transistors and the active clamping, boosts switching frequency up to 500 kHz. This design architecture also increases power density significantly while maintaining high efficiencies—a prototype achieved greater than 95% efficiency as well as a power density of 12.5 kW/L.

Thermal Management for Automotive High Power Density

Many new electronic devices are making their way into the modern automotive system, leading to an increase in heat generated within the vehicle. There’s also a trend to replace hydraulic and mechanical devices with smart electronic devices. Energy efficiency is on the rise due to this new effort, but designers now need to manage these added heat loads. The quantity of heat sources continues to climb; thus, they need to be spread out over most of the vehicle’s limited volume.

Cooling techniques will significantly improve power density. Some key areas within the vehicle have various levels of cooling:

- Level 1 applies to heat spreading in the semiconductor package, where today’s technologies use copper, copper/tungsten, and copper/moly heat spreaders.

- Level 2 applies to heat transfer/spreading from the device package to the chassis. Modern technologies use copper and aluminum heat spreaders.

- Level 3 applies the transporting of heat from the chassis to the system heat exchanger. This method uses forced air flow as well as pumped liquid loops.

- Level 4 applies to heat dissipation through the system heat exchanger. Modern technologies enable air-cooled heatsinks and radiators.

The “level of cooling” method in an automobile typically uses a heat spreader, temperature control, and heat transport. These advanced thermal-management methods, such as HiK plates and VCHPs, have passed laboratory development stages and are being deployed in mission-critical military and space systems.

Read more articles in the Power Management Series: Delving Into Power Density

References

1. “High-Power Density Reference Design for Automotive Vehicle-to-Everything (V2X) Power,” Texas Instruments Test Report, PMP22648.

2. “A GaN 500 kHz High Current Active Clamp Phase-Shifted Full-Bridge Converter with Zero-Voltage Switching over the Entire Line and Load Range,” EPE'18 ECCE Europe.

3. “Advanced thermal management technologies for high power density automotive equipment,” Advanced Cooling Technologies.

4. “Supporting the Introduction of the PoC Method for High-speed Automotive Networks Through Component Selection Efficiency,” Murata.