TDK Discusses Their Latest MEMS-based CO2 Gas-Sensor Platform

Reprinted with permission from Evaluation Engineering

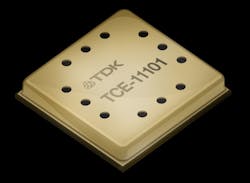

Recently TDK released the InvenSense TCE-11101, a miniaturized ultra-low power MEMS gas sensor platform for direct and accurate detection of CO2. The device introduced new technology as part of the new SmartEnviro family, and its small size and low power requirement enables battery-driven consumer and commercial devices of all form factors. The TCE-11101 is housed in a 5- x 5- x 1-mm 28-pin LGA package, and requires minimal external components to complete the design.

To get a better understanding of the new sensor platform and what it means to the design engineer, we spoke with Dr. Sreeni Rao, Senior Director, Emerging Business, InvenSense, a TDK Group Company.

EE: So you have this new novel family of CO2 sensors, they’re MEMS-based, correct?

Dr. Rao: Right. our new SmartEnviro family is expected to encompass our MEMS sensors in the areas of gas sensing and general environmental sensing. The first product that we launched is a MEMS-based carbon dioxide sensor. Where we are differentiated is that we have an ultra-low power, extremely small solution, and because we are based on a bulk MEMS process, we expect to be at a pretty competitive cost point as well. We're offering the performance advantages that other solutions that may have the cost power advantages may not be able to offer.

EE: Now, CO2 sensing... There are a lot of application spaces within that, from residential room monitoring, to fermentation process management, all the way to agricultural sensing.

Dr. Rao: That’s right.

EE: That's a lot of app spaces.

Dr. Rao: It is, and the space is certainly very fragmented. All the applications you mentioned are appropriate for a MEMS sensor, definitely, but what I would say is there are only some of those spaces or applications that are really hurting for want of a solution that is competitive in terms of power consumption in terms of the space it occupies, and of course, in terms of cost.

For example, if you are talking about an industrial application in a safety environment, et cetera, where the number of deployments is very low, cost may not be a big consideration. And in cases where there are few of them, when there is access to wired power, power may not be the issue as well.

But what the current solutions have done so far is they have restricted the availability of carbon-dioxide sensing into applications that could potentially use them if only a solution was available that was good performance-wise, that is, and that was low power, low cost, and small deployable easily with digital interface, etc. So what TDK is doing is really stepping into that void, if you will, to offer a solution that has all the above advantages.

EE: Now, so then, because it's so broken up and because there are so many ways that you can use CO2 sensing, what are some of the primary application spaces that you intend to target initially?

EE: Turn on a fan.

Dr. Rao: Turn on a fan or open a vent on or something. Right? So those applications are the most prominent. And, one more thing I will point out, is with the increasing awareness about things like virus infections with COVID, for example. There is some reason to believe that an environment that is high in carbon dioxide content could also be potentially unhealthy in other ways. So I think it becomes even more important to monitor the level of gases around you, and CO2 seems to be one of the biggest culprits on that account.

EE: Now, one of the reasons we mentioned agricultural applications is we had the opportunity to take a look at the European FACE project, which is a major agricultural project that they're doing in the vineyards, where they've carbon dioxide tanks. And they're blowing carbon dioxide on the vineyards so that they can see what's going to happen to wine quality in 20 years when CO2 levels are 10, 15% higher. So they've got apparatus spraying CO2 on the fields.

So they've got to have sensors to make sure that they're not putting too much to make it an accurate scientific situation. There have got to be a lot of little applications like that, where you're doing something... either it's a process, or it's a research project, or it's something where you're leveraging the ability to put a carbon dioxide sensor in a place where either you were not able to before because of size or power requirements.

Dr. Rao: Right. Exactly. I think that last point is what is most important in what our thinking is because the kind of examples that you gave earlier... like, for example, in an agriculture scene where we need to monitor CO2 coming from a tank or doing an experiment. Those kinds of things probably are being served reasonably well by the CO2 solutions that exist today. The market is not without CO2 sensors at this point. There are bulky, big, and power-wise hungry, and cost-wise expensive sensors available.

They've been available for the last several decades now. They're based on optical techniques typically, and they use a lot of bulky space in order for the optical signal to be properly altered, if you will. So applications like what you're mentioning, where the amount of usage is small, and they're not that sensitive to cost.

EE: Academia is incredibly sensitive to costs. Yes, on the surface, there are probably a lot of applications where you might think, "Oh, it could be used, but not necessarily..." But there's probably a big inherent pent-up demand for better CO2 sensors because, as you point out, it's a mature space in a lot of ways. But as you also point out, a lot of the solutions are bulky.

Dr. Rao: That's exactly what we have found in our market investigations and such, and we feel that the market is ripe for disruption with a solution that makes the best possible intelligent trade-offs, going down from the bulkiness, from the power hungriness of traditional solutions.

On the other end of the spectrum, I should mention, there are MEMS-based solutions today that may be able to address the power and space concerns of the optical solution, but that are inherently based on principles that may not be accurate, that could be prone to inaccuracy, and that may not be precise. So I think in coming up with this new technique that we have implemented in MEMS, we have actually come up with the best possible, the most intelligent trade-off between those two ends of the spectrum, if you will.

EE: Have you had some feedback yet from any of your beta customers on the product? What kind of feedback are you getting?

Dr. Rao: The universal feedback is the kind of applications that a solution like this could open up is really enormous. So most customers are very happy that we are able to offer a miniaturized MEMS-based, mass-producible good performing carbon-dioxide sensor. The point is that the sandbox that carbon dioxide sensing could play in has become much more expanded as a result of solutions like this. That is where we see we are going to make a big difference, and we have evaluation kits to help engineers address these new applications.

EE: Because it's such a wide space and there are so many ways to get into, do you see any spaces that may find new purpose because of the availability of these sensors?

Dr. Rao: Right. Absolutely. So even with the existing solutions, people have been trying to keep track of carbon dioxide and other gasses, right? For example, one space that I can tell you is food safety. When food is fresh food versus when food is not fresh or, say, rotting or whatever else is going on, the kind of gases that are emitted are so much different from the kind of gases that are emitted by fresh food. Right?

So being able to monitor the freshness of your food supply chain and making sure that, for example, things like salmonella poisoning or any other kind of poisoning we keep hearing about every season in US and other countries around the world, there could be ways of using gas sensors and deploying them appropriately so that things like that can be avoided, also, or at least there is enough notice about things like that as well. So gas sensors could become an important part of the food supply chain as well. And that's an application that has not become enabled so far because there has not been a proper solution that is miniaturized and is able to attack the cost and the power and those limitations.

EE: Right now, they're shipping all this COVID vaccine around, and it's all packed in dry ice. I recognize they probably have some kind of sensor for temperature, but would it be useful to have a carbon dioxide sensor so you could say, "Hey, the dry ice is run out in the shipment"?

Dr. Rao: There could be because you want to make sure that... See, carbon dioxide is a silent killer, right? You cannot smell it. You cannot really do anything that you can react to just by the carbon dioxide being around you. So, yes, an ability to monitor if there is a leakage in a package like that is definitely important. I think that makes all the sense in the world.

When you get into your car and turn on your air conditioning on a hot day, you know that air conditioners most of the cars today use what are known as HFCs are CFCs, correct? So it turns out that most of the HFCs, as you know, are very, very hard in such an environment. And it turns out the carbon dioxide, if used as a coolant or a freezing medium, is actually much less harmful to the environment than these other gases, HFCs. So a lot of new cars models are coming up in Europe and China and Japan, and other places are actually switching to use carbon dioxide as a coolant liquid or a coolant medium than HFCs.

So imagine when carbon dioxide is being used, unlike HFCs, which are really present in very small PPB quantities and may or may not harm you as a person, carbon dioxide could make you drowsy. If there is a leakage in the car, God forbid, it could make the driver drowsy and could result in an accident. So it becomes important to monitor the carbon dioxide leakage situation, right, in a track system of the car. And we are seeing those applications in that area, which is really close to the kind of scenario that you just mentioned, leakage monitoring.

EE: As you point out, there are legacy solutions, but there are a lot of places where there might be dangerous accumulations of carbon dioxide, and many people aren't thinking of it. Like maybe there’s a shed, and you’re trying to mulch, and maybe not thinking about the outgassing of the mulch pile or... All kinds of little things that people might not think of that might be an application space. But now, if you have an inexpensive, small, accurate sensor, it can open up some things.

Dr. Rao: Exactly. That's exactly true, and that is really what we feel is the direction the industry is going. And this has been a space that did not get enabled for a very long time because there was no appropriate solution. And the reason TDK is able to achieve this or accomplish this is because, as you can imagine, unlike, for example, a motion sensor or a gyroscope, right, which basically use MEMS technology with some algorithms running on top of the sensor, what a gas sensor needs is not just the MEMS technology but also materials technology. Because at the end of the day, gas sensing has to happen by some level of interaction with some materials, right?

Maybe they are inert materials. Maybe there's some chemical materials. Maybe there are some metal oxide materials. So the interaction of the gas with that material is what really makes the MEMS a good transducer, and then that transfers into data that you can go off and do some processing and computation on, right? Therefore, in order to produce a really good competitive, really good gas sensor, what you need to bring these three components to the table- good materials expertise, good MEMS expertise, and good algorithms expertise.

Dr. Rao: TDK, as you know... I'm sure you do. Inherently, we are a materials company. TDK started with magnetic materials.

EE: The first thing that comes to mind is a Nakamichi cassette deck and TDK metal tape.

Dr. Rao: Right. So materials science is our core bread and butter. And with a company like InvenSense that became a part of our family, we have excellent MEMS technology, as well as our materials expertise. So you put all these three together to produce a really good and differentiated gas sensor.

EE: Before I turn off the recorder, do you have any last thoughts on gas sensing or this sensor in particular? Or any last words or ideas you'd like to leave with our audience?

Dr. Rao: Oh, I would just add that gas sensing, like you rightly pointed out in the beginning, is a very fragmented market because of the application space being small and lots of applications around. Correct?

But in addition to that, we must also keep in mind that gas sensing by the types of gases that need to be monitored is also a very fragmented market. Carbon dioxide is only one of the many gases that are important. It just happens to be a big culprit in many areas that we are, in this day and age, most concerned about. But there are other harmful gases. There are lots of them.

There is methane, for example. I don't know if you are from the East Coast or the Midwest in the US, but you can imagine that most basements have the gas heaters for keeping the houses warm, and they work on a combination of methane and other gases. And monitoring data leakage is important as well. You turn on gas stoves, and there can be material accumulation. New furniture and new carpets typically emit formaldehyde, and formaldehyde is a cancerous gas, right?

So the point I'm making is there are a number of other gases that are also important. CO2 just happens to be the biggest culprit and probably one of the most difficult gases to fence because CO2 is inert. It doesn't react with any other gases to be able to sense it properly. Right? So the gas sensing market, in general, is such a huge opportunity for people that are making MEMS sensors and people that are interested and that have solutions that can bring the three technologies that I mentioned earlier, materials, MEMS technology, and algorithms technology, to the table.

About the Author

Alix Paultre's Archive

Editor-at-Large

Also check out Alix's main author page for his latest articles.

An Army veteran, Alix Paultre was a signals intelligence soldier on the East/West German border in the early ‘80s, and eventually wound up helping launch and run a publication on consumer electronics for the US military stationed in Europe. Alix first began in this industry in 1998 at Electronic Products magazine, and since then has worked for a variety of publications in the embedded electronic engineering space. Alix currently lives in Wiesbaden, Germany.

Also check out hjis YouTube watch-collecting channel, Talking Timepieces.