Keithley curve tracers, SMUs augment power-device test

The August print issue of EE-Evaluation Engineering includes a special report on power electronics test. In preparation for that article, we asked test equipment vendors to provide information on their products and strategies. Lee Stauffer, senior staff technologist; Robert Green, senior market development manager; Jonathan Tucker, senior marketing manager; and Ming Wang, product manager—all of Keithley—provided extensive feedback. In the Q&A below, they elaborate on points raised in the print article.

Question: What configurations of the Parametric Curve Tracer (PCT) are available for power test?

Answer: Four standard configurations (low power, high current, high voltage, and high current and high voltage) are available, as well as a variety of test fixture and interface options. These systems include the key elements necessary for power device characterization. PCT measurement channels are configured from Keithley Series 2600B and Series 2650A SourceMeter source measure unit (SMU) Instruments and an optional Model PCT-CVU multifrequency capacitance-voltage (C-V) meter. They offer dynamic range and accuracy that is orders of magnitude beyond what a traditional curve tracer could provide. The C-V meter is designed for C-V measurements on two-, three- or four-terminal devices. Capacitances from picofarads to 100 nF can be measured, with test frequencies from 10 kHz to 2 MHz, which makes it well suited for applications like measuring the parasitic capacitances on a high voltage SiC transistor.

Could you elaborate on the source-measure units?

Series 2600B SMU Instruments offer single- and dual-channel models that combine the capabilities of a precision power supply, true current source, 6½-digit DMM, arbitrary waveform generator, pulse generator, and electronic load—all into one tightly integrated instrument. This family of models offers the test and measure industry’s widest dynamic range: 10-A pulse to 0.1 fA and 200 V to 100 nV. The result is a powerful solution that significantly boosts productivity in applications ranging from bench-top I-V characterization through highly automated production test.

The Model 2651A high-power system SourceMeter instrument is designed to characterize and test high current and high power electronics, including those fabricated from compound semiconductors like SiC and GaN. Its wide dynamic range (50 A, 40 V, 100 fA) helps improve productivity in applications across the R&D, reliability, and production spectrums. It can be combined with another Model 2651A to increase the maximum current range to 100 A, with other Series 2600B SourceMeter SMU instruments to create SMU-per-pin test systems, or with the Model 2657A high power system SourceMeter instrument to configure a high-power PCT test system capable of 3000 V and 100 A.

The Model 2657A high power system SourceMeter instrument has the ability to source, sink, and measure up to 3 kV/1 fA for precise characterization of a wide variety of power semiconductors in applications across the R&D, reliability, and production spectrums, including those fabricated from compound semiconductors like SiC and GaN.

With its 7-A DC and pulse current capability, the Model 2460 SourceMeter SMU is optimized for characterizing and testing the operating performance of high power materials, devices, and modules such as SiC and GaN devices, DC/DC converters, power MOSFETs, solar cells and panels, LEDs and lighting systems, electrochemical cells and batteries, and much more.

At what stage of the design, development, and production process are these products used (for example, debug, validation, characterization, production, failure analysis)?

Keithley’s Parametric Curve Tracer configurations, SourceMeter SMU instruments, and power supplies are widely used in design and development:

- During the design stage, given that engineers are trying to gather as much information as possible on a new device, they need to acquire a broad range of parameters. These include breakdown voltage, on-state current (DC), on-state current (pulse), drain/collector leakage current, gate/base leakage current, on-state threshold voltage or cutoff voltage, forward transfer admittance or forward transconductance, on-state resistance, input capacitance, output capacitance, and reverse transfer capacitance.

- During the development stage, engineers tend to focus more on how their devices will be commercialized, and how they might fail. Here, the PCT configurations, SMU instruments, and power supplies are often used in characterization applications designed for developing device specifications and for failure analysis.

Series 2600B SourceMeter SMU Instruments, and the Series 2650A SourceMeter instruments are also well suited for use in production test because of their high test throughput and high measurement speeds when configured in systems that include an appropriate probing system (for testing on wafers) or test fixture (for testing packaged parts). Although the Model 2460 doesn’t offer quite the speed of the Series 2600B instruments, it is also appropriate for some production test applications because of its 7-A DC and pulse current capability.

Keithley’s Parametric Curve Tracer configurations (including the Models 2657A and Model 2651A) offer the power required for the vast majority of high-power device design and development applications and are optimized to address the characterization and test needs of research, reliability, failure analysis, and power device applications engineers; power device designers; incoming inspection technicians; and many others. Applications include

- power semiconductor device characterization and testing at both the wafer and packaged parts level,

- characterization of GaN and SiC, LDMOS and other devices,

- reliability studies on power devices, and

- incoming inspection and device qualification.

Series 2290 high-voltage power supplies are often used in characterization applications in research, design, and reliability labs for the following types of tests:

- high voltage device breakdown testing,

- high voltage component testing,

- insulation testing, and

- high voltage resistivity measurements.

Series2600B SourceMeter instruments and the Series 2650A SourceMeter instruments are also suited for use in production test because of their high test throughput and high measurement speeds when configured in systems that include an appropriate probing system (for testing on wafers) or test fixture (for testing packaged parts). Although the Model 2460 doesn’t offer quite the speed of the Series 2600B instruments, it is also appropriate for some production test applications because of its 7A DC and pulse current capability.

Keithley’s Parametric Curve Tracer configurations (including the Models 2657A and Model 2651A) offer the power required for the vast majority of high power device design and development applications and are optimized to address the characterization and test needs of research, reliability, failure analysis, and power device applications engineers; power device designers; incoming inspection technicians; and many others. Applications include

power semiconductor device characterization and testing at both the wafer and packaged parts level;

characterization of GaN and SiC, LDMOS, and other devices;

reliability studies on power devices, and

incoming inspection and device qualification.

Series 2290 high-voltage power supplies are often used in characterization applications in research, design, and reliability labs for the following types of tests:

- high-voltage device breakdown testing,

- high-voltage component testing,

- insulation testing, and

- high-voltage resistivity measurements.

What types of measurements are your instruments making (for example, I-V or other electrical parameters or thermal or other parameters?

Keithley test instruments primarily perform I-V measurements. The Parametric Curve Tracer can also be configured to perform capacitance and C-V measurements.

A Parametric Curve Tracer configuration can, depending upon the exact instrument configuration chosen, extract these power transistor parameters:

- breakdown voltage (Bvdss, Bvceo);

- on-state DC current (Vdson, Vcesat, Vf);

- on-state pulse current (Vdson, Vcesat, Vf);

- drain/collector leakage current (Idss, Ir/Icbo, Iceo);

- gate/base leakage current (Igss, Ib);

- on-state threshold voltage or cutoff voltage (Vth, Vf, Vbeon, Vcesat);

- forward transfer admittance or forward transconductance;

- on-state resistance (RDS(on), Vcesat);

- input capacitance (Ciss);

- output capacitance (Coss); and

- reverse transfer capacitance (Crss).

The Model 2460 SourceMeter instrument and Model 2651A and Model 2657A High Power System SourceMeter instruments are well suited for high power testing, especially in the areas of the characterization of new materials (such as SiC and GaN) and components and module testing.

Do you offer any options (for example, software or fixturing) that are particularly applicable for power electronics test applications?

Keithley’s ACS Basic Edition software (included in PCT configurations) provides complete device characterization, including both real-time trace mode for quickly checking fundamental device parameters like breakdown voltage and full parametric mode for extracting precise device parameters. ACS Basic Edition goes beyond traditional curve-tracer interfaces by offering a broad array of parametric test libraries. Users have complete control of all test resources, allowing the creation of more advanced tests than previously possible on a curve tracer.

The Model 8010 High Power Device Test Fixture provides safe and easy connections for testing packaged high power devices at up to 3000 V or 100 A. The Model 8010 provides connections for a high-voltage SourceMeter instrument (Model 2657A), one or two high current SourceMeter instruments (Model 2651A), and three low-power SourceMeter instruments. This allows devices with two terminals (diodes) or three terminals (transistors) or even four or five terminals to be characterized safely and accurately. The Model 8010 has full interlock capability for up to six SourceMeter SMU instruments. Integrated protection circuits protect the low voltage SourceMeter SMU instruments from high voltages that the Model 2657A can output should a device fault occur. It includes both a high current (100 A) and a high voltage (3,000 V) test socket. Various replacement test socket modules are available, including TO-247, TO-220, axial lead, and a blank socket module that allows building a custom socket. In addition to standard banana jumpers, the Model 8010 has rear-panel scope and thermal probe ports to simplify system integration. The new Model 8010-DTB-CT Tektronix Curve Tracer Adapter Module supports the use of Tektronix curve tracer test modules with the Model 8010 fixture.

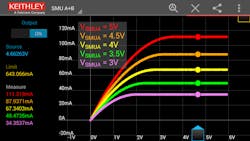

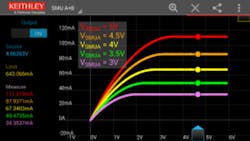

The free IVy app for Android-based smartphones and tablets is designed to interact with a Series 2600B SourceMeter SMU instrument via its front-panel USB interface. It offers a fast, easy-to-use touchscreen tool for characterizing 2- and 3-terminal devices. By leveraging the power of smart mobile devices, IVy transforms the Series 2600B into a powerful instrument that enables users to visualize, interact, and share measurement results more efficiently, while helping them gain a deeper understanding of their devices’ behavior. IVy leverages a smart device’s built-in display (pan/pinch/zoom/swipe), computing (interaction with the instrument), and communication (Wi-Fi, email, etc.) capabilities so users can visualize measurement data, interact with the instrument, and share results easily—all without programming. It supports simultaneous control over the source level (using an on-screen slider) and monitoring of test results (on the smart device’s graphical display). This unique capability makes it easy to analyze I-V characteristics, DUT stability, response time, or drift in a circuit visually.

How do you address the safety implications of high-voltage, high-current test?

When configuring a test system, protecting the operator from electric shock must always be the first priority. One primary way to do this is to use a safe test enclosure that surrounds the DUT and any exposed connections. The Model 8010 High Power Test Fixture permits safe testing of packaged high power semiconductor devices at up to 3 kV. Pairing a safe enclosure with a safety interlock also minimizes risk of electric shock when the user changes test connections. Keithley SMU instruments and Series 2290 power supplies are equipped with a safety interlock; when properly installed, this interlock ensures that the hazardous voltages are disconnected whenever a user opens the test fixture or accesses the wafer in a probe station.

In addition to protecting the operator, it is important to consider the interactions between all the instruments connected to the device terminals. If a lower voltage SMU instrument is connected to the device during a breakdown characterization, a device fault can result in high voltage being present across this lower voltage SMU instrument. The Model 8010 includes built-in protection to protect the lower voltage SMU instrument in such applications.

The Model 8020 High Power Interface Panel includes built-in overvoltage protection for the lower power 200-V SMU channels in a test system, eliminating the need for external protection modules and the complications involved in connecting them. Screw terminals located under the interface panel’s top cover provide for inserting any two-terminal resistor in series with the high voltage or 200-V SMU channels. Resistors are housed within a safe, shielded enclosure, which manages the safety and electrostatic interference issues associated with using series resistors for oscillation suppression and gate leakage measurements, as well as when using resistors to enforce absolute current limits for breakdown voltage measurements.

For applications higher than 3,000 V, the Model 2290-PM-200 Protection Module ensures that low-voltage instrumentation is protected from voltages higher than 240V. The protection module shunts high voltage to prevent it from damaging the low voltage devices. In addition, Keithley works with probe and fixture manufacturers, such as Signatone, which provides a 10-kV test fixture for safe testing of high voltage components.

Are there any other unique features about your solutions you would like to emphasize?

PCT configurations offer two modes of operation: trace test mode and parametric test mode. Trace test mode presents an interface similar to the controls and display found on a traditional curve tracer. It allows for rapid generation of device characteristics and for interactive operation based on viewing the results in the graph. It incorporates knowledge of many device types and tests, which speeds and simplifies test setup. An on-screen slider provides real-time control and acts like the knob found on the traditional curve tracer. Trace test mode is very handy for quickly determining whether a device is good or bad or finding its boundaries. This mode is often used during device development or failure analysis.

Parametric test mode offers access to all of the advanced capabilities of the SMU instruments within the PCT, allowing users to specify exactly how a test is to be performed. Built-in test libraries provide support for the most common device and test types; a vector math formulator supports accurate parameter extraction on these devices. Once configured, an entire suite of tests can run autonomously without operator intervention. This mode is often used in device qualification, process monitoring and datasheet generation applications.

See related article “Teledyne LeCroy elaborates on power test.”

Additional information

Keithley also provided links to additional resources:

- Achieving Fast Pulse Measurements for Today’s High Power Devices—Application Brief

- Measuring Pulsed Waveforms with the High Speed Analog-to-Digital Converter in the Model 2651A High Power System SourceMeter Instrument

- Testing to 100 A by Combining Keithley Model 2651A High Power SourceMeter Instruments Application Note

- VDS Ramp and HTRB Reliability Testing of High Power Semiconductor Devices with Automated Characterization Suite (ACS) Software

- Optimizing Reliability Testing of Power Semiconductor Devices and Modules

- Creating Multi-SMU Systems with High Power System SourceMeter Instruments Application Note

- Testing Power Semiconductor Devices with Keithley High Power System SourceMeter SMU Instruments

- Using the Arbitrary Waveform Capabilities of the Series 2600B and Series 2650A System SourceMeter SMU Instruments to Perform Ford EMC-CS-2009.1 CI 230 Power Cycling Testing

- Solving Connection Challenges in On-Wafer Power Semiconductor Device Test Application Note

- Breakdown and Leakage Current Measurements on High Voltage Semiconductor Devices

- Application Note: DC/DC Converter Characterization

- Application Note: Power Supply Measurement and Analysis with Bench Oscilloscopes

- Re-Inventing High Power Semiconductor Device Characterization

- Measuring Low Resistance Devices with High Current Using the Model 2460 SourceMeter SMU Instrument

- I-V Characterization of Photovoltaic Cells and Panels Using the Keithley Model 2450 or Model 2460 SourceMeter SMU Instrument

- There’s an Unsung Hero on Your Workbench: The SourceMeter SMU Instrument

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.