Connected cars are evolving into mobile data centers, with communications extending from CAN, LIN, and FlexRay to MOST and BroadR-Reach. And cellular and wireless technologies like Wi-Fi in its 802.11p implementation are increasingly playing a role in automotive applications. Test challenges will span low-frequency audio infotainment applications through mmWave automotive radar.

Cellular functionality can be particularly challenging for automakers. “Product development schedules for automobiles are much longer than those for smartphones,” pointed out Craig Hendricks, senior technologist, Automotive Focus Team, Anritsu. “This means for the cellular connectivity built into cars to be competitive and relevant, automakers need to begin their development with the most advanced cellular technology possible.”

Noah Reding, senior business segment manager at National Instruments, summarized automotive test requirements. As cars increasingly move toward connectivity and autonomous operation, test system requirements are changing faster than ever with each vehicle needing to be tested as a converged system, he said, in an interview at NIWeek in Austin in August.

According to Averna in a case study,1 “Automotive OEMs … must constantly innovate in order to provide comprehensive test coverage, accelerate throughput, and extend the value of their test systems.” The case study details how Averna helped one client accelerate automotive radar production testing by replacing a VXI-instrument-based test system with one based on PXI modules. The new system integrated multiple custom anechoic chambers and supported the test and labeling of up to 10,000 radar units per chamber per week.

Chris Martinez, strategic planning manager at Tektronix, outlined the variety of test requirements the automotive industry faces. “The testing needs for automotive require a wide range of product types,” he said. Requirements include making highly sensitive DC and power-related measurements as well as both time-domain and RF measurements. “Driven by the connected car and applications like advanced driver assistance systems, the automotive market requires higher performance measurement products that can address higher data-rate (>1 GB/s) measurement and compliance needs,” he said. He cited relevant Tektronix and Keithley offerings:

- DC and parametric measurement products like the DMM and the source measurement unit (SMU);

- power measurement products including oscilloscopes and power analyzers;

- bench products including power supplies, signal generators, and loads;

- oscilloscopes used in general debug and with options tailored to protocol test of FlexRay, CAN, and LIN as well as compliance solutions for the latest automotive serial buses like automotive Ethernet (BroadR-Reach and 100BASE-T1); and

- mixed-domain oscilloscopes and spectrum analyzers for RF-specific measurements.

Design and test

Jungik Suh, marketing program manager, Automotive and Energy Solutions, Keysight Technologies, emphasized the importance of design as well as test. “A good design-for-test strategy upstream during the design and development phases helps to maximize test coverage and yields when products move into the high-volume production stage,” he said. “At Keysight, we offer solutions that cater to the full design and test lifecycle from early design simulation through R&D verification and manufacturing. For early stage designers and R&D engineers, Keysight is practically a one-stop shop for all their benchtop needs, right through manufacturing where our high-volume, fully automated in-circuit test systems and functional test solutions ensure the automotive electronics work as they are designed whether in the lab or on the road.”

Trevor Smith, business development manager for Pico Technology, said his company has two divisions offering solutions for automotive applications. The first is “… focused on the upstream design, development, calibration, production, and test activities where our products are used by engineers and technicians prior to a vehicle leaving the factory—and usually prior to it being built because the bulk of our products are used by development engineers.”

Smith said, “The second division is focused on the after-sales test, diagnosis, and repair of vehicles both in the franchised dealer network and by repairers in the independent aftermarket. Here PicoScope offers a solution tuned to the needs of service with a combination of high resolution, moderately fast sampling (up to 400 MS/s), and protected higher voltage inputs. Additional software and accessories extend the capability to deal with high-voltage safety, pressure, and temperature plus a system that makes the diagnosis and repair of noise, vibration, and harshness problems simple, objective, and repeatable. At present, the highest speed requirements commonly presented to repair technicians have been CAN and FlexRay. As we move forward, Pico Technology already has the capability to provide service solutions to meet the needs of BroadR-Reach 100 Mb/s, should that be required, and will in the future introduce solutions to handle 1,000 Mb/s.”

New automotive test products

As for specific automotive test products, Averna at NIWeek in August launched what the company calls the first all-in-one infotainment RF signal source based on the NI vector signal transceiver. The software-defined AST-1000 can generate all common infotainment RF signals, including AM/FM, DAB, GPS, HD Radio, and Sirius/XM to assist in validating automotive infotainment systems.

Alex Pelland, product marketing manager at Averna, said at NIWeek that the AST-1000’s software-defined architecture, enabled by the NI VST, will soon allow the instrument to accommodate new signals, including connectivity protocols like Bluetooth and Wi-Fi as well as non-RF signals like CAN for bus monitoring. The source’s FPGA framework easily accommodates new signals related to navigation (GNSS), audio/video, and connectivity, Pelland said, thereby saving on instrument costs.

In addition, the source features seamless integration with Averna URT RF players and signal generators to protect customer investments, and it offers an easy-to-use interface for quick signal generation and easy test setups, Pelland said. The flexible PXIe architecture allows integration of other applications/cards. The source is rack-mountable and can handle lab validation as well as functional and end-of-life testing.

“We’ve been working closely with the team at NI to develop an RF signal source based on the NI vector signal transceiver, so it’s fitting to launch our AST-1000 during NIWeek 2016,” said Pelland.

“The Averna AST-1000 is a great example of bringing innovative test solutions to market through our Alliance Partner Network by combining Averna’s extensive industry knowledge with NI’s flexible PXI-based platform,” said Michael Schneider, principal product manager at NI, in a press release. “The AST-1000 is sure to appeal to automotive infotainment developers who want a software-defined instrument that will continue to evolve to cover their ongoing test requirements.”

Hardware in the loop

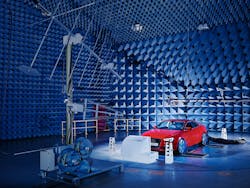

For its part, NI at NIWeek announced turnkey hardware in the loop (HIL) simulators (Figure 1) built on an open, modular architecture to help automotive embedded-software testers maintain quality while handling the demands of shortened schedules, changing test requirements, and reduced manpower. Companies don’t want to buy a black box, Reding

said, explaining that with the new simulators, NI has standardized the common features while allowing custome rs and partners to add customization as needed via NI’s new hardware for standardizing signal routing with switches, loads, and signal conditioning.

Courtesy of National Instruments

The NI systems integrate technologies like camera processing and RF I/O, along with traditional HIL components, into a single system built on open, off-the-shelf hardware and software platforms. The HIL simulators are built on the PXI and CompactRIO open platforms and powered by the VeriStand real-time test configuration and logging software and LabVIEW system design software. NI HIL systems use both a real-time operating system and FPGA technology to deliver customizability while still taking advantage of commercial-off-the-shelf components to reduce long-term maintenance risk.

NI also touted its second-generation VST, introduced in July. At an NIWeek presentation, Niels Koch, who specializes in radar systems at Audi (Germany), said, “The combination of the industry’s widest bandwidth and low-latency software-designed instrument allowed us … to identify problems very early in the design phase that were previously impossible to catch.” With the VST and its LabVIEW-programmable FPGA, he added, “… we were able to rapidly emulate a wide range of diverse scenarios, thus influencing safety and reliability aspects in autonomous driving.”

Hardware and software

Suh at Keysight said the company offers automotive design and test solutions for broad automotive application segments including connected car, automotive radar, body and security, power train, battery, and power converter. “One of the key differentiators Keysight offers is in providing our customers with both hardware and software solutions for a complete design and test lifecycle from early simulation through R&D and manufacturing,” he said.

“For the connected car arena specifically, Keysight offers a range of powerful tools for the early research and development stages of the design process,” he said. The tools include SystemVue, 89600 VSA, and ADS software as well as signal generators and analyzers. “With the recent acquisition of Anite, Keysight has extended its solutions for our automotive customers,” he added, supporting virtual drive testing, which helps customers create a complete field test environment in the lab; automotive over-the-air performance testing; and 802.11p and cellular-channel emulation with V2X fading profiles. Keysight also addresses component test and physical and protocol layer verification with scopes, arbitrary waveform generators, and network analyzers, he said.

Automotive protocols

Teledyne LeCroy also supports protocol test for automotive applications. Robert Mart, product manager at the company, said, “We offer software packages for the CAN/CAN FD, FlexRay, MOST, and BroadR-Reach protocols, all of which come under the connected-car test umbrella. Naturally, the oscilloscopes that support these packages also are germane to the topic, one example being the WaveRunner 8000 oscilloscopes that range in bandwidth from 500 MHz to 4 GHz and another being the HDO 12-bit oscilloscopes.”

He added, “We refer to Teledyne LeCroy’s low-speed serial-data packages as TDME (trigger, decode, measure/graph, and eye diagram) packages, because they cover all four of these critical aspects of measurement and analysis of serial protocols.”

He elaborated, “On the triggering front, all of our serial triggers are borne of deep knowledge of the standard at hand. Our serial decode, search, and table tools turn the oscilloscope into a highly capable protocol analyzer that quickly and intuitively correlates protocol data to the physical-layer waveforms. The measurement and graphing capabilities enhance the trigger and decode packages for faster debugging and validation.” And finally, he added, “Eye-diagram capabilities enable display of up to four simultaneous eye diagrams; these can be different protocols or the same protocol measured at different points in the signal path.”

Tektronix also targets its oscilloscopes at automotive protocol test applications. The company’s Martinez said, “Tektronix’s oscilloscope products can be configured to support a wide range of protocols used in automotive,” including automotive-specific buses like FlexRay, CAN, and LIN as well as other buses used in automotive applications like USB, Ethernet, SPI, and I2C. In addition, Tektronix offers compliance support for automotive standards like MOST and BroadR-Reach (Figure 2), providing automated compliance using oscilloscopes and signal generators. Finally, he added, Tektronix probes are used extensively for measuring voltage and current across the vehicle’s electronic systems.

Courtesy of Tektronix

Courtesy of Pico Technology

As for Pico Technology, Smith said, “Our oscilloscopes span a range of bandwidths, sampling rates, and resolutions to meet many of the needs in [the automotive test] area, and PicoScope (Figure 3) is used by vehicle manufacturers, equipment suppliers, and component manufacturers within their engineering activities. Our sampling scopes offer bandwidth to 20 GHz and can support both TDR and TDT with applications including cable integrity testing while our real-time scopes provide bandwidth to 1 GHz and sampling rates to 5 GS/s.”

RF and wireless test

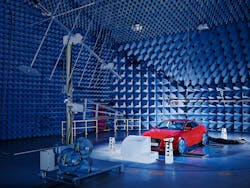

Rohde & Schwarz has a range of test products specifically for automotive applications, covering infotainment (cellular, connectivity), automotive radar test and simulation, and other driver-assistance applications as well as EMI/EMC in-vehicle network test solutions covering BroadR-Reach, CAN, LIN, and FlexRay.

Greg Kregoski, automotive segment manager for North America, said, “As a leader in all aspects of RF and wireless test, we have a full portfolio of test solutions in addition to many years of knowledge and expertise.” Some particular challenges for automotive customers, he said, relate to LTE/WLAN/BT coexistence, EMC (in tight, condensed spaces), eCall, and 802.11p.

“Our CMW wireless test platform, the R&S CMW wideband radio communication tester, offers universal, efficient test solutions for all modern cellular and noncellular standards,” he said. “The R&S CMW is the world’s most widely used test-and-measurement platform for development, production, and service. It meets all of the requirements for a state-of-the art wireless communication tester. This platform also can emulate network operation under realistic conditions for protocol and RF tests.”

Kregoski continued, “In anticipation of the eventual deployment of a connected-car scenario that may consist of both 5G and 802.11p where both standards must be supported to test the entire connected-car ecosystem, we support both physical- and protocol-layer testing. We offer both discrete pieces of test equipment (FSW, CMW, and SMW200) and an entire RF validation system (ITS100).”

He described the ARTS9510 automotive radar target simulator (Figure 4) as a unique test solution that can simulate range, velocity, and target size, up to four targets, in a stationary environment (saving space and time) combined with the R&S FSW signal and spectrum analyzer with up to 2-GHz analysis bandwidth.

Courtesy of Rohde & Schwarz

Kregoski added, “For EMC, we have all the necessary components ranging from EMI debugging tools, receivers, broadband amplifiers, software, and accessories (antennas, turntables) to complete turnkey chamber solutions.”

From LTE to EMI-prone environments

Martinez at Tektronix said his company’s products are used extensively in the development phase including characterization, debug, and compliance across the automotive ecosystem, starting with the silicon providers, moving on through tier I/II device (for example, ECU) manufacturers, and extending to the OEMs for system-level development and integration. Additionally, he said Tektronix products are used by test houses as part of system and compliance testing.

Martinez added, “The challenges range from implementation of common wireless standards like Wi-Fi, Bluetooth, and LTE into a harsher environment that is more prone to EMI and other RF interferences. The Tektronix RF portfolio helps customers by offering support for specific technologies such as Wi-Fi but also can serve mixed-domain applications that may require analysis of both the time and the frequency domains. In-vehicle testing is addressed by our ultra-portable USB spectrum analyzer (RSA306B).”

Hendricks at Anritsu listed several instruments for automotive test applications. “For cellular modems used in connected cars, the MD8475A and MD8475B signaling testers can be used to conduct functional and system-level testing while the MT8820C and MT8821C radio communication analyzers (Figure 5) can conduct RF parametric tests.”

Courtesy of Anritsu

Anritsu also offers the MS2830A and MS2690 Series signal analyzers and the MT8870A universal wireless test set, which can test various systems (for example, DSRC V2X modules and remote-keyless entry and tire-pressuring monitoring systems) using Bluetooth, WLAN, GNSS, and cellular technologies.

“For testing automotive radar, Anritsu recommends the MS2840A signal analyzer as well as the MS46522B-086 ShockLine two-port performance VNA that can be used to test the cables and antennas used in the 79-GHz and 77-GHz systems,” he said. “Another ShockLine VNA, the MS46122A, can test the efficiency of wireless charging systems being developed for cars.”

Conclusion

The foregoing review of automotive test suggests a key takeaway: you can expect to find fewer test products dedicated to automotive test requirements. In some cases, you can rely on a solutions provider like Averna to tailor a product like NI’s VST to your automotive test needs. In other cases, you’ll be using more general-purpose products ranging from simulation and design software to radio communications test sets for automotive test applications as cars become converged collections of technology. Suh at Keysight, which is supporting 5G early research, concluded, “Design and test solutions for 5G will play an important role in future V2X/V2I applications as well as the autonomous self-driving car.”

Reference

- Averna Accelerates Production Testing for Automotive Radar, Averna Technologies, Case Study, 2014.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.