Digicom to present ways to mitigate device failure at BIOMEDevice

Dec. 4, 2017

2 min read

Oakland, CA. Digicom Electronics Inc. announced it will present ways to mitigate device failure in manufacturing processes at BIOMEDevice, December 6-7 in San Jose. In addition, Digicom will be celebrating its 35th year in the California Bay Area.

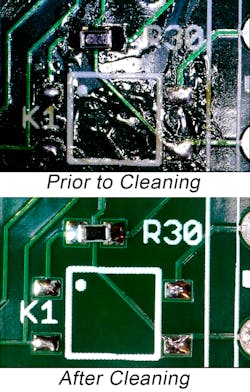

“Device failure can often be attributed to printed-circuit-board contamination or problems with the solder joints,” explained Mo Ohady, general manager of Digicom Electronics. “Digicom has spent several years researching ways to produce ultraclean boards and to build-in reliability throughout the assembly process. We developed a proprietary Diamond Track Cleaning Process, which independent testing agencies verify produces boards with zero ion contamination. In addition, studies show a 50-60% reduction in defect level when using nitrogen in the reflow process. Digicom generates its own nitrogen and pipes it to all our soldering processes, including hand, reflow, and selective soldering. 100% of our boards are inspected. We feel that it’s essential that an EMS company take every step to ensure the integrity of the devices they prototype and assemble.”

Digicom helps companies with their complete process from design review through prototyping, component sourcing, manufacture, test, and process validation. It said it has been recognized as one of the first companies to have been certified for the new AS9100:2016 (Rev D) aerospace quality and ISO 9001:2015 standards, and it has ISO 13485:2003 medical-device-quality, quality-system regulation 21 CFR 820, ITAR, and numerous other certifications.

See related articles:

About the Author

RN (editor)

This post was selected and edited by Executive Editor Rick Nelson from a press release or other news source. Send relevant news to [email protected].

Sign up for our eNewsletters

Get the latest news and updates