CFX demo complements test and inspection at IPC Apex Expo

San Diego, CA. About 20 equipment vendors, software providers, and customers from across the electronics industry participated in an IPC Connected Factory Exchange (CFX) Showcase at IPC Apex Expo, held Feb. 27 through March 1 in San Diego. IPC also presented innovation awards, and many companies highlighted a variety of test, inspection, and other products related to the design and production of PCBs and related electronic assemblies.

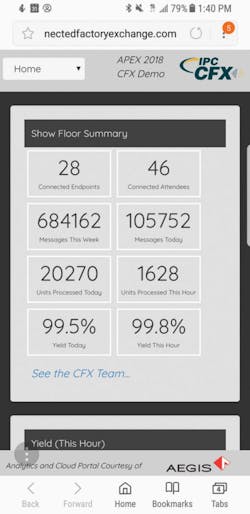

The CFX technological demonstration operating in real time delivered standardized machine data through the cloud and onto visitors’ mobile phones when they scanned a QR code. The scan brought up a mobile device website (Figure 1) driven by the CFX cloud server. Companies streaming live CFX data at Apex in support of the CFX demonstration included Aegis Software, ASM, Creative Electron, CyberOptics, Europlacer, Flexlink, Fuji, Hanwha, Heller Industries, JBC, KIC, Koh Young Technology, MIRTEC, Parmi, Pillarhouse International, Speedprint Technology, TRI, Universal Instruments, Viscom, and ViTrox. Additional CFX member companies and organizations promoting the CFX standard include BTU, Cogiscan, The Hermes Standard, Huawei, SPEA, and YXLON.

Apex Exhibitors included 32 companies who nominated 34 products and services for the Apex Expo 2018 Innovation Awards. IPC presented the four winners during the Feb. 28 keynote session:

- DfR Solutions won for the temperature-based FEA capabilities in its Sherlock automated design analysis software, which analyzes, grades, and certifies the expected reliability of products at the circuit-card assembly level.

- JBC Tools won for JBC Net, a software system that manages and optimizes the hand soldering process, standardizes parameters, and controls operator performance.

Metcal earned an award for its Connection Validation Robotic Soldering System. IPC said that robotic soldering is becoming more commonplace as manufacturers look to reduce risk and increase productivity. Metcal’s new CV Robotic Soldering System combines its patented CV technology and a new smart interface system.

- Orbotech Inc. won for its Ultra Dimension, an AOI system for advanced PCB manufacturing processes.

“The IPC Apex Expo Innovation Awards allow us to celebrate the innovators and forward thinkers who are changing the technological landscape of the electronics industry,” said John Mitchell, IPC president and CEO. “The product and service submissions were certainly innovative, and the companies did an exceptional job in identifying their product’s unique value in the industry. The innovative submissions directly indicate the strength of the electronics industry and its ability to respond to new challenges resulting from emerging technologies,” Mitchell added.

In addition, many companies highlighted a variety of test, inspection, and other products related to the design and production of PCBs and related electronic assemblies, as predicted in our April report1 on the topic. And several highlighted innovations they hadn’t disclosed by the time our February report went to press. For example, Keysight highlighted its i367x Series fully automated in-line 4-module in-circuit test system, which can test a single board or two or four boards in parallel.

Siemens announced the Valor IoT Manufacturing Analytics product, a comprehensive big-data and business-intelligence platform that monitors and manages global electronics manufacturing operations for accurate, real-time manufacturing utilization and overall equipment effectiveness (OEE). Building on the acquisition of Mentor Graphics, Siemens said it continues to invest in software solutions to realize innovation and power each customer’s digital enterprise. This new solution is powered by Siemens’s MindSphere.

Saki, a provider of automated optical and X-ray inspection and measurement systems, demonstrated its new 5th-generation 3D AOI, 3D SPI, and 3D AXI systems and software. Saki reported its AOI and SPI systems maintain position accuracy of 3 μm to 9 μm at 3σ for 99.7% positioning accuracy. The company reports that its systems are the first to offer a choice of three resolutions: 7 μm, 12 μm, and 18 μm. For AXI, Saki said its 3D BF-3 AXI system achieves 100% head-in-pillow detection and enables LGA inspection and measurement. It inspects for voids inside the solder joints of IGBT modules—a capability important in the automotive industry. Finally, the company said, Quality-Driven Production, Saki’s tool for M2M communication, ensures that the data and information that is communicated to third-party systems is valid and accurate.

Optomec announced the launch of its Aerosol Jet HD system for electronics packaging. The Aerosol Jet HD System is designed to address demanding electronics packaging challenges, including the increasing density of electronic components. The Aerosol Jet HD system is a compact, configurable production platform that can dispense a range of electronics materials with features as small as 20 microns. The system can also produce larger features, from hundreds of microns to millimeters in a single pass, and it can print wide-area conformal coatings from 100 nm to tens of microns in thickness.

Seica showcased its new, fully automated, Pilot V8 next > Series flying prober (Figure 2), which provides up to 20 mobile test resources for an electronic board, including probes that can supply up to 3 A, high-resolution cameras for automatic optical inspection, barcode-reading capability, lasers, capacitive probes, pyrometers, optical fiber sensors for LEDs, flying connectors for boundary-scan and on-board programming, and high-frequency probes for measurements above 1.5 GHz. Targeting medium and high-volume production, the Pilot V8 next > Series will be available in a fully automated version. The company also highlighted the Dragonfly next > AOI system, which provides optical inspection capabilities for through-hole technology (THT) as well as conformal coating (CC). Both the THT and CC versions can inspect one or both sides of a board, which is conveyed on a standard SMEMA-compliant rail conveyor, driven by an intuitive and streamlined management software, which will allow commissioning and application program development in a few hours, the company reported.

Courtesy of Seica

Distributor Ascentech LLC exhibited the Inspectis AB range of high-definition camera microscopes and related noncontact optical inspection systems designed for quality control, repair, and rework. The company also highlighted GEN3 Systems’ AutoSIR2 surface insulation test system, which measures changes in surface insulation resistance. It can measure 256 channels in less than eight seconds. It can apply voltages of 1 V to 1,000 V and offers a resistance measurement range of 106 Ω up to 1014 Ω. Finally, Ascentech highlighted the W-30 Freesight and the Flexia BGA inspection systems from Optilia.

JTAG Technologies highlighted its Visualizer, which incorporates a range of CAD-tool import filters. Users can import schematic data direct from Mentor, Cadence, Altium, and Zuken tools as well as board layout information in ODB++ and a dozen other vendor-specific formats. Introduced in the latest version of Visualizer is the new Maps feature, which offers a basic test-accessibility view by a simple click of the mouse. The view can be fine-tuned by adding key component descriptions to a lookup table. Customizable colors can indicate test-coverage levels or access types, and a color-coded schematic can be displayed or printed. Once the design has been optimized for boundary-scan test coverage and committed to layout, final application development can begin in the JTAG ProVision developer tool.

In addition, LPKF Laser & Electronics demonstrated its rapid PCB benchtop prototyping system, the ProtoMat S63 (Figure 3), designed to help electronics engineers make PCB prototypes in minutes or hours, instead of waiting for a design to come back from the board house. The system’s high-speed spindle can produce structures as small as 100 μm. Other features of the ProtoMat S63 include automatic tool change (15 tools), automatic milling width adjustment, optical fiducial recognition (camera), and an optional vacuum table. LPKF demonstrated laser machines for board assembly and manufacturing as well as plastic welding lasers.

Courtesy of LPKF Laser & Electronics

And finally, Aegis Software unveiled new quality-management capabilities that complement the existing incoming- and in-process quality-assurance features of its FactoryLogix software.

Reference

- Nelson, Rick, “Tools from software to X-ray systems round out PCB test and inspection,” EE-Evaluation Engineering, February 2018, p. 12

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.