September Special Report: Regenerative power supplies & sources

Download this article in .PDF format.

Returning the power

As manufacturers of all types of mechanical equipment work toward using energy efficiently, regenerative power technology has taken a major role in reducing operating costs. Power regeneration is the process of recovering kinetic energy created by a motor when stopping or braking, and then converting that energy to electricity and feeding it back into the power grid. Hybrid and electric vehicles are the first examples that typically come to mind, but other applications that involve frequent stopping and starting—such as hoists, cranes, elevators, spindle drives, and decanter centrifuges—can also put significant energy to recycled use.

This is equally true in electronic test. With energy efficiency at a premium for those performing high-power tests, power supply customers must factor in a product’s lifetime operational costs, which often exceed initial capital investment. Today, vendors of regenerative power supplies and sources market not only their solutions’ low cost of ownership, but many newer solutions also feature lower floor or rack space usage, low heat dissipation, and mimimal required maintenance.

As for what challenges vendors of regenerative power supplies & loads are facing today, Drodt pointed to the effective control of the heat generated from the power stage and optimizing the entire system with a cost-effective design.

“In essence, these are two products in one, and a four-quadrant solution may not be the right fit for all,” Drodt explained. “Makers of regenerative sources and supplies need to find the right balance between efficiency, heat generation, function, and cost in order to for the product to make sense to the market. We think we’ve done that at Chroma.”

To dive further into this topic, we at EE gathered input from various vendors and their partners that produce and/or market regenerative power supplies & sources. We asked them for their thoughts on technology trends, challenges, and customer needs, as well as what new solutions they’ve recently made available and how they’re being applied. Here’s what they told us.

What’s trending?

What technology or market trends are vendors seeing in the area of regenerative power supplies & sources?Herman vanEijkelenburg, director of marketing at PPST Solutions: “New trends in regenerative DC power supplies are led by the need for ever-increasing output voltage ranges to support ever-increasing EV battery pack power levels, which requires higher battery voltage to keep current levels and associated cabling and connectors in-check. This results in products with capabilities to 1500Vdc and more becoming more prevalent in recent years. Another trend is the need for multi-channel battery test systems based on regenerative DC source/sink power supplies to support testing multiple battery packs simultaneously.”

Martin Weiss, product director at NH Research: “As electrification continues to accelerate across many industries, we are seeing two key technology trends in regenerative power supplies and sources that are bidirectional. On the DC side, we are seeing increased use of regenerative power supplies as battery emulators, and in AC we are seeing increased demand for grid simulation. A battery emulator is a bidirectional DC source solution that simulates a battery, while a grid simulator is an AC source solution that simulates a wall outlet. Regenerative bidirectional sources with battery emulation and grid simulation capabilities provide significant testing advantages in industries such as electric vehicles (EV), solar (PV), energy storage systems (ESS), aerospace and defense.”

Allison Harvey-Goodman, product manager at Keysight Technologies: “One trend in regenerative power supplies is for higher voltages of 500V and above, and higher power of 10kW and more. With the rapid growth in automotive and energy markets—driven primarily by the growth in hybrid-electric and electric vehicles (HEV/EV)—comes the need for higher voltage, and higher power regenerative sources. As the automotive market transitions to HEV/EV, and battery voltages have shifted from 12V to well over 300V and power in the tens of kilowatts, high voltage, high-power regenerative supplies are needed to adequately emulate and test these HEV/EV batteries. Conversely, as more low-voltage subsystems replace mechanical ones, the total amount of current inside a vehicle can rapidly increase to tens or hundreds of amperes, thus driving the need for high-current regenerative power supplies.”

Brian Hsu, USA product marketing manager at Preen AC Power Corp.: “There are more and more requirements on the regenerative AC grid simulator and regenerative DC power supply. The regenerative AC grid simulators are mainly applied on grid tie devices and smart grid/micro grid-related equipment testing. The regenerative DC power supplies are used in energy storage, battery testing, DC motor, etc.”

Dr. Raghavan Nagarajan, senior staff application engineer – wind and T&D expert – at Infineon Technologies: “In regenerative sources such as wind energy, the main technology trend is going for high power-rated wind turbines for both onshore and offshore wind sites.”

Challenges

What key challenges are regenerative power supply & source vendors or their partners facing today?Turner, Elektro-Automatik: “Market demands of flexibility, reduction in physical space requirements and cost. In many applications subassembly test could be required prior to full assembly test. As example, Engineers ask for the flexibility to separate (Master/Slave) a 1MW regenerative DC supply into four 250kW systems instead of purchasing one large supply and several smaller ones. As always, floor space is valuable and often in short supply so our customers value smaller solutions. In general, regenerative supplies are priced at $/Watt and customers expect cost savings as power increases.”

vanEijkelenburg, PPST Solutions: “Increasing power demands are pushing up the size of regenerative power products to ever higher power levels. This applies to AC sources, DC supplies, and electronic loads alike. As power levels increase, energy savings resulting from using regenerative products can result in significant cost savings for customers on both utility bills and HVAC bills.”

Dr. Nagarajan, Infineon: “The key challenge faced by wind energy in general and wind turbines in particular is optimizing the total cost of ownership. Wind farm operators have to calculate the payback period for their investments. For this reason, reliability and energy efficiency are becoming increasingly important.”

What are customers asking for?

What features or innovations are customers asking for in regenerative power supplies & sources?Drodt, Chroma: “Mostly, our customers ask for versatility in the supply’s functionality; meaning the same unit could be applied as regenerative source or a regenerative load. This versatility reduces the footprint in the lab as well as minimizes the cost. Chroma has responded to our customers by developing a series of regenerative electronic loads and bidirectional power supplies.”

Weiss, NH Research: “Customers are demanding modular configurations, expandable power, integrated safety features, wider operating envelopes, built-in measurements, and faster transient response times for the testing of today and tomorrow’s products. There is a general trend by all modern suppliers to use SiC and GAN-based switches. These devices permit higher switching frequency and therefore higher power densities.”

vanEijkelenburg, PPST Solutions: “Capabilities and features of regenerative AC source and DC power supplies are largely similar to those of conventional, i.e. unidirectional AC sources and DC power supplies, with the main exceptions being the requirement for special operating modes related to PV inverter testing. This testing includes LVRT and IEC test modes for AC sources and special modes related to battery charge/discharge profile programming and SoC monitoring functions on DC source/sink DC supplies.”

Turner, Elektro-Automatik: “High-speed voltage and current slew rates. Energy storage devices like batteries or fuel cells’ dynamic response to load changes is in the µsec (micro) so to accurately test or simulate the dynamic profile the supply should offer high speed changes in power. Zero cross-over transition deadtime between source and sink mode, which relates to a seamless change from source to load mode allows complex voltage patterns to be modelled.”

Harvey-Goodman, Keysight: “As power supplies are going higher and higher in power, the size of the solution also grows. Density of test instruments is becoming more and more important. Customers are asking for compact, high-power regenerative power supplies to handle high-power requirements and to aid in shrinking rack space.”

Hsu, Preen AC Power Corp.: “For the regenerative AC grid simulator, there are increasing requirements on the UL1741 SA and fault ride through testing.”

Compliance/Regulatory

What recent or upcoming compliance, regulatory, or compatibility issues—if any—are impacting technology in Regenerative Power Supplies/Sources?Drodt, Chroma: “Regulatory standards such as VDE4105—a standard regarding the integration of power production units into a low-voltage system—have included a regenerative AC source usually classified as laboratory test instrument into the regulatory scope. New requirements such as this will definitely provide challenges for development.”

Turner, Elektro-Automatik: “E-mobility is booming so that short time-to-market cycles play an increasingly important role. At the same time, slowly developing compliance standards pose new challenges for manufacturers. Standards like V 123 is an electrical test standard which verifies the safety and electrical parameters of high-voltage components in cars. This test requires subjecting the equipment under test to conditions like overvoltage, undervoltage, start pulses, load dump, and overcurrents. Compliance test conditions of up to ± 40V/msec requires newer generation DC supplies to offer high-bandwidth amplifiers.”

Hsu, Preen AC Power Corp.: “The new UL-1741SA compliance test may require voltage ride through and frequency ride through for three phase grid tie devices.”

Now on the market

Here’s what vendors shared as newer solutions or accessories they’ve recently introduced in the area of regenerative power supplies & sources, and their key features.Drodt, Chroma: “Chroma has recently launched the 61800-100, which is a 105kVA regenerative grid simulator with versatile functions such as regenerative AC loading, XHV high voltage up to 900VLN, and high frequency options. The parallel capability of 61800-100 allows output power rating up to 1MVA based on customization. The 61800-100 105kVA regenerative grid simulator is applicable for micro-grid, PV inverter, PCS/ESS, UPS, EVSE, and DC quick charger test applications. To complement their regenerative grid simulators, Chroma has introduced its new line of bidirectional DC power sources. Designed specifically for bidirectional applications, the Chroma 62000D series provides 5kW, 10kW, and 15kW at 100V to 1800V. Up to 150kW can be achieved when used in parallel. The 62000D can both sink and source current, providing both a power supply (source) and an electronic load (sink) in one 3U high unit.”

vanEijkelenburg, PPST Solutions: “One of our latest regenerative product offerings is the Cinergia three-in-one power system, which can be configured for multiple applications as either a regenerative AC or DC power source, regenerative AC or DC load, or multi-channel battery tester. This allows the end-user to deploy the same unit to any application he may have. This rather unique capability is particularly popular with energy research labs and universities as it allows them to buy a single piece of equipment and repurpose it a will for a wide range of power test requirements.”

Harvey-Goodman, Keysight: “Keysight recently introduced the RP7900 Series Regenerative Power System and the EV1003A Power Converter Test Solution for hybrid and electric vehicles (HEV/EV) and home energy management systems (HEMS). The RP7900 Series is a family of 5kW and 10kW bi-directional, regenerative DC power supplies delivering up to 950 V and up to an industry-leading ±800 A in small 3U high package, saving valuable rack space. The EV1003A Power Converter Test Solution for hybrid and electric vehicles (HEV/EV) and home energy management systems (HEMS) offers all the same capabilities as the RP7900 Series but also adds the ability to handle faults and ensure the output is disconnected with a redundant safety disconnect system.”

Turner, Elektro-Automatik: “EA has released our new EA-PSB 10000 Series, which expands our popular EA-PSB 9000 Series. The new PSB 10000 is a 4U rack-mounted power supply and engineered with advanced SiC power conversion devices switching at approximately 150 kHz. Both the PSB 9000 and PSB 10000 offer zero cross-over transition at an industry-leading 96% efficiency. A single PSB 10000 19” rack chassis hosts 30kW of power, which is an increase in power density of 33% over previous models and up to 75% over comparable models from other manufacturers. The high-bandwidth amplifier offers <1msec voltage and <300µsec current 10-90% slew rates. Standard configurations are offered from 30kW to 2MW of power.”

Hsu, Preen AC Power Corp.: “The PAS-F is a regenerative AC grid simulator designed for UL-1741SA compliance testing that can support for up to 2MVA standalone (non-parallel connection) testing requirements.”

Applications

What novel or unique applications have these vendors’ regenerative power supplies & source solutions been used for recently?Drodt, Chroma: “Recently, we connected of five sets of our 61800-100 Grid Simulators in parallel to provide a total output power of 525kVA for high power DC quick charger testing. In addition, we’ve built automated test systems with bidirectional configurations for our customers, satisfying burn-In applications for power conversion products including EV chargers, batteries, telecom power supplies, DC/DC converters, AC/DC power supplies, and DC/AC inverters.”

Harvey-Goodman, Keysight: “Our recent examples include:

- Emulating an electric vehicle for electric vehicle supply equipment (aka charging station) test

- Emulating an electric vehicle supply equipment for electric vehicle charging test

- Testing an electric power steering motor requiring the regenerative power supply to act as a load, quickly handle transients, and seamlessly switch from sourcing to sinking

- Testing a hybrid power conditioner for home energy management system where the regenerative power supply emulated the battery

- Satellite power management system test utilizing a bidirectional regenerative power supply to emulate a satellite’s battery (charge/discharge) and test the power management system.”

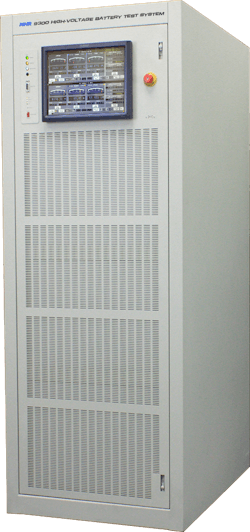

Weiss, NH Research: “NHR’s regenerative 9300 Bi-directional DC source can safely emulate a high voltage battery accepting fast charge power, returning over 90% of the power back into the facility. NHR’s regenerative 9410 AC Grid Simulator can verify the AC product performance, while NHR’s battery emulators can emulate an energy storage system.”

Turner, Elektro-Automatik: “Inductive charging technologies for automotive and transportation industries. EV HV cooling systems, fuel cells, and onboard EV chargers. Marine industry power controlling system for photovoltaics inverters and backup batteries. Submarine battery test for hybrid controls. EV OBCs and DC-DCs, likewise PV technology, which is now becoming bidirectional.”

Hsu, Preen AC Power Corp.: “The PAS-F series solution had been widely used on PV inverter testing, micro inverter testing, and burn-in or aging testing applications.”

For more information

About the Author