Industry Insights: Automated Test Makes Complex Tasks Manageable

While many applications using automated test procedures involve high-speed manufacturing test processes, automated test is also a way to optimize complex test procedures. Be it simulation for wireless, wired, or even physical systems, automated test solutions can make complex testing situations manageable. Here are some recent news items related to automated test:

A solution for evaluating the video quality of 5G devices was recently developed by a partnership between Spirent Communications and TOYO using Anritsu’s SmartStudio NR (SSNR) Network Simulator and Spirent’s Attero and Umetrix Video software. Operating as a 5G Call Box, Anritsu's MT8000A simulates a 5G base station and core network with a state-machine-based GUI.

The solution can simulate a range of 5G network conditions, such as Standalone (SA) and Non-Standalone (NSA) topologies at FR1 or FR2 frequencies, without creating protocol scripts. Throughput, mobility, VoNR, EPS-Fallback, SMS, CMAS, CDRX, and other functional tests can be performed with the GUI. SSNR flexibility and ease in reproducing a 5G network situational environment to analyze video quality. Automation environments can be configured quickly, and Spirent’s Attero can emulate situations accurately and in a repeatable manner to fully stress-test Next-Gen IP platforms and networks.

Changeable filters test the effect of impairments on specific packets or types of traffic, and the Umetrix Video evaluation system scores the QoE (Quality of Experience) using Video Mean Opinion Scoring (V-MOS) from the receive-side only, supporting video-streaming services and video-content analysis, allowing faster and lower-cost repeatable design, regression, and competitor benchmarking tests.1

Simulation can help optimize any design, including the cables and connectors in a vehicle's wire harness. In a recently released publication, Rosenberger, maker of connectors and cable assemblies, applies ZVEI TLF0101 guidelines and examines optimization practices. Their work provides for a standardized format for exchanging parameters of electro-thermal component models to simulate a vehicle's electrical network for the purpose of thermal optimization. This process can greatly shrink the weight and complexity of the wire harness, addressing connector size and weight, cable cross-section, and potential development times, depending on the deployment.

Able to simulate an entire vehicle virtually, the system helps reduce cable cross-sections. For example, Rosenberger's HVS 240 connector is 50 mm² across, offering a volume and weight savings of up to 30% as well as up to 50% thinner than non-optimized solutions in a design. Rosenberger and Leoni, a cable and wire manufacturer, developed a demonstrator, using cable, connectors, and power to demonstrate how the process can optimize cable requirements. Rosenberger will provide information on how it was done in accordance with ZVEI guidelines using their HV product portfolio.2

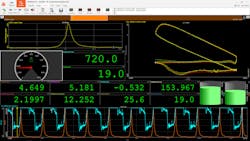

Dewesoft released DewesoftX 2021.2, which includes upgrades to the Modal Analysis, Power Analysis, and Combustion Analysis modules, among others. The Modal Analysis Module allows engineers to perform assessments of structures. It now automatically detects the measured frequency response functions and shows the curve fitted results in a new stabilization diagram. It calculates and displays an AutoMAC matrix with a table that shows natural frequencies with damping ratios.

The Power Analysis Module takes advantage of the processing capability of your computer’s GPU (graphical processing unit). Leveraging the GPU enables real-time execution of all power module calculations at high sampling rates. Even a mid to high performance notebook computer with an Nvidia GPU will easily run 3 x three-phase power modules at 5 MS/s/channel. This is a huge technical step forward that dramatically increases processing speed while performing advanced real-time calculations.

The Combustion Analysis Module includes a brand new knocking detection algorithm that sharply increases the module’s ability to handle gasoline power combustion analysis, ideal for detecting pre-ignition events. Diesel engines from small cars to the biggest two-stroke ship engines in the world are also well supported.

Additional new features and capabilities of DewesoftX 2021.2 include enhanced soft synchronization of GigE cameras, the ability to display amplifier status parameters on the screen in the measurement mode, and much more. To learn more please visit: https://dewesoft.com/dewesoft-x-software/dewesoft-x-2021-2-released.3

2. evaluationengineering.com, “Simulating a Vehicle for Wire Harness Optimization,” June 3, 2021

About the Author

Evaluation Engineering Staff

Check out the latest articles by the Evaluation Engineering Staff.