Ocean of Things (OoT) Biomimetic “Bug” Skims Water and Collects Data

What you’ll learn:

- Why is there a need for mobile, autonomous, micro-robotics for aquatic data collection?

- How materials were combined to provide the needed flow of bacteria in water to generate power.

- How the assembly was configured for motive power and sensing.

One of the many challenges with small-scale robotics for collection of water-related data (often referred to as “bugs”) involves providing power for their motion and sensors. Addressing this issue, a research team at the State University of New York at Binghamton researchers developed a self-powered, untethered biomimetic bug that can skim across the water, which they hope will greatly advance aquatic robotics (Fig. 1).

The project is funded by the Office of Naval Research, aligned with the Defense Advanced Research Projects Agency (DARPA) and its Ocean of Things (OoT) program. It’s part of an ambitious initiative that aims to deploy thousands of miniaturized, cost-efficient, floating nodes across vast oceanic expanses. These “smart floats” will be equipped with an array of specialized sensors designed to capture a comprehensive range of environmental data, such as water temperature, pollution levels, the movements of commercial vessels and aircraft, and the behaviors of aquatic mammals.

By enabling the periodic wireless transmission of this data, these smart floats should enhance the ability to monitor and understand marine environments. The work done here in mobile bugs enhances their ability to collect and respond to environmental data by addressing the limitations of conventional smart floats, which are typically passive and stationary.

The self-sustaining, self-replenishing energy system for compact aquatic robots was inspired by biological digestion. It uses microbial fuel cell (MFC) technology, where organic materials found in aquatic environments are converted into electricity through catalytic oxygen-reduction (redox) reactions. To ensure a steady supply of these organic substrates for microbial viability, the units integrate what’s called a “biomimetic Janus membrane” with asymmetric surface wettability.

Self-Pumping Without Reverse Flow

The Janus membrane is a hydrophobic-hydrophilic interface, inspired by natural examples such as cacti, lotus leaves, spider silk, and desert beetles. It’s positioned with its hydrophobic side facing the water; therefore, the interface facilitates the self-pumping of organic substrates into the MFC without reverse flow.

This hydrophobic characteristic contributes to the main buoyancy force, thus enabling the aquatic robot to float, and has an important role in its operational efficiency. (Recall that in ancient Roman religion and myth, Janus was the god of beginnings, gates, transitions, passages, and endings. He’s usually depicted as having two faces; our month of January is named for this god.)

Their fuel cell used a vertical, layered configuration to achieve an even distribution of the organic substrate across the anode and minimize internal resistance to boost system efficiency (Fig. 2).

The design ensures consistent microbial exposure to substrates, enhancing bio-electrochemical reactions. At the same time, the decrease in internal resistance was key to augmenting electrical conductivity, thereby enhancing MFC performance.

They used a polypyrrole-coated carbon cloth for the anode because of polypyrrole’s superior conductivity and support for microbial colonization throughout its surface, allowing for efficient electron transfer. The cathode was crafted from polypyrrole-coated platinum (Pt/C)-decorated carbon cloth, leveraging the catalytic properties of Pt/C to accelerate oxygen reduction. Nafion 117, a material with exceptional proton conductivity and stability, was chosen as the proton-exchange membrane (PEM).

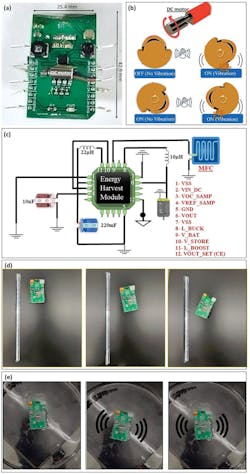

The aquatic robot, which is designed to mimic the structure of a water strider, is built on a lightweight, low-density platform that integrates its components efficiently (Fig. 3).

The platform is constructed from cost-effective and durable polycarbonate plastic, a material often used in printed circuit boards. This material, coupled with the hydrophobic characteristics of the Janus anode, enables the robot to move on water surfaces with ease because of its buoyant and insulating properties.

Small DC Motor Powers Water Movement

The array of MFCs is linked to a compact power-management system to supply power to a small DC motor that’s positioned on top of the robot platform. This setup enhances the MFC array’s output voltage and stores the energy in an integrated capacitor, which in turn powers the low-power DC motor, automating the robot’s movement on water. The strategically placed motor induces vibrations during rotation, ensuring the robot’s smooth propulsion across the aquatic environment.

The system includes voltage-regulation circuits to provide a stable output voltage despite the variable output voltages typical of energy-harvesting sources such as MFCs. The design features load-switching capabilities for precise energy distribution and enhanced use of stored energy.

Current consumption is exceptionally low, usually between 10 to 25 µA, and a 470-µF capacitor is used as the external energy storage component. They achieved sufficient power output to drive the integrated DC motor by arranging these units into an array—power density is 135 µW cm2 with an open-circuit voltage (OCV) of 0.54 V from a single MFC unit.

The capability of the MFCs to consistently accumulate charges enables uninterrupted operation of the motor function, in line with the goal of sustainable operation in aquatic settings. Power output is close to 1 mW. It’s enough to operate the robot’s mechanical movement and some sensors that could track environmental data such as water temperature, pollution levels, the movements of commercial vessels and aircraft, and the behaviors of aquatic animals.

The fascinating project is described in detail in their clearly written paper “Revolutionizing Aquatic Robotics: Advanced Biomimetic Strategies for Self-Powered Mobility Across Water Surfaces” published in Advanced Materials Technology. It includes details of the concept, applications, implementation, design rationale, test results, and fabrication specifics.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.