In my previous article “Measure Self-Discharge Using OCV on Lithium-Ion Cells,” I covered how to measure the self-discharge rate of a lithium-on cell by observing how its open circuit voltage (OCV) drops versus time. In the article, I mentioned temperature can also cause a drop in OCV. Now, let’s explore more.

What is TCV?

The OCV of the cell is determined by the cell’s state-of-charge (SoC). However, the temperature of the cell is another important factor, as the cell’s OCV will vary with temperature. This effect is called the temperature coefficient of voltage (TCV) of the cell. It’s measured in microvolts per degree C (μV/°C).

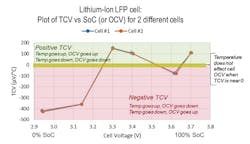

TCV can be positive, where an upward change in temperature leads to an upward change in OCV and a downward change in temperature leads to a downward change in OCV. Likewise, TCV can be negative, where an upward change in temperature leads to a downward change in OCV and a downward change in temperature leads to an upward change in OCV. The polarity and size of the cell’s TCV is a function of the cell’s SoC (see figure).

This plot of TCV versus SoC of a cell shows positive, neutral, and negative TCV values.

For lithium-ion cells, a large positive TCV would be 200 to 500 μV/°C, while a large negative TCV would be −300 to −500 μV/°C.

Why Does TCV Matter?

For many applications, these small changes in OCV caused by the effect of temperature aren’t significant. However, there’s a particularly important time when TCV does matter—when you’re measuring the cell’s self-discharge.

In my previous article, self-discharge was determined by looking at the change in OCV over time using the delta-OCV method. The delta-OCV method relies on the fact that cell OCV is a function of SoC. The delta-OCV method takes days to make a measurement. When an engineer decides to use a short time to make a delta-OCV self-discharge measurement, he will be forced to measure very small differences in OCV, such as 2 mV or less. Also in my previous article, I shared how voltmeter accuracy comes into play when delta-OCV is just a few millivolts or less. But now, let’s consider the effect of TCV.

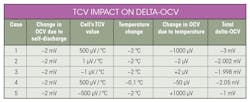

If the cell’s OCV can change by 500 μV/°C, and the delta-OCV you’re trying to measure is only 2 mV, this temperature effect can be a very significant portion of the delta-OCV. If the temperature is held constant, then TCV won’t matter. But in a normal, well-controlled environment, temperature swings of 1 to 2°C are common. For example, with a TCV of 500 μV/°C, a 2°C change means the cell’s OCV changes by 2 × 500 μV, or 1 mV, just due to temperature. The table provides several cases showing how TCV can impact a delta-OCV measurement.

For case 1, the cell has a large positive TCV. When the cell experiences a 2°C downward change, its OCV is reduced by 1 mV due to temperature, which adds to the downward change in OCV caused by self-discharge. In this case, the delta-OCV is now −3 mV, with −2 mV from self-discharge plus −1 mV from temperature. The result is a delta-OCV measurement that appears 50% higher than the actual delta-OCV caused by self-discharge.

For cases 2 and 3, the cell has a small TCV; therefore, the OCV change caused by temperature is negligible. When TCV is small, no special consideration needs to be made to account for temperature effects on OCV.

For case 4, even though the cell has a large positive TCV, there’s only a small temperature change. Once again, the OCV change caused by temperature is negligible. The lesson here is that keeping the cell temperature constant is an excellent way to nullify the TCV effects and to ensure good measurement results. An environmental chamber can be used to keep temperature constant during delta-OCV measurements.

Note that environmental chambers cycle on-off to hold their temperature constant. While the average temperature may be well-controlled, the temperature could bounce up and down in the chamber as it cycles on and off trying to hold the average temperature constant. This cycling of the chamber will appear as a time-varying OCV and can be considered as a low-frequency cyclical noise signal on top of the −2-mV delta-OCV.

For case 5, the cell has a large negative TCV. When the cell experiences a 2°C downward change, its OCV is increased by 1 mV due to temperature, which partially offsets the downward change in OCV caused by self-discharge. In this case, the delta-OCV is now –1 mV, with −2 mV from self-discharge plus +1 mV from TCV. The result is a delta-OCV measurement that appears 50% lower than the actual delta-OCV caused by self-discharge.

If the TCV is known and the temperature is accurately measured during the self-discharge measurement, then the effects of temperature can be removed from the delta-OCV measurement and the true change in OCV due to self-discharge can be determined.

Conclusion

The OCV of lithium-ion cells depends on SoC as well as temperature. The effect of temperature, called TCV, can range from a large positive number through zero to a large negative number. When making millivolt- and microvolt-level measurements on a cell, the cell’s TCV must be understood and considered unless the cell’s temperature remains absolutely constant. When using the delta-OCV method to measure cell self-discharge, the TCV of the cell can contribute significant error to the self-discharge measurement, and so it must be understood and properly considered.

About the Author

Bob Zollo

Solution Architect for Battery Testing, Electronic Industrial Solutions Group

Bob Zollo is solution architect for battery testing for energy and automotive solutions in the Electronic Industrial Solutions Group of Keysight Technologies. Bob has been with Keysight since 1984 and holds a degree in electrical engineering from Stevens Institute of Technology, Hoboken, N.J. He can be contacted at [email protected].