Download this article in PDF format.

What if you were suddenly designated as the engineer to prototype a new company's (Industrial Internet of Things) IIoT system? Would you be ready or need to learn more? Evaluating hardware and software for implementing an IoT network isn’t that easy. But it can be manageable if you know the suppliers that offer what you need. If you’re responsible for designing products targeting such systems, consider the following process.

Sponsored Resources:

- Creating a State-of-the Art, Cost Effective Energy Harvesting Bluetooth Low Energy Switch

- Internet of Things Development Kit Set Up

- Internet of Things (IoT) Development Kit (IDK)

Step #1: Do a site survey.

Most IIoT systems are wireless sensor networks, which are diverse and unique. It’s always helpful to experience the environment where your products will be used, such as office buildings, factories, process control plants, and others. You can see first-hand how the sensors are used. Determine the availability of any wired networks that might be employed. Estimate the range and other wireless path factors related to the use of wireless at each node. Once you see a real-world application, you will have a better perspective of what’s needed to design.

Step #2: Choose a technology.

IIoT wireless sensor networks can be implemented with a wide range of different wireless technologies. Wi-Fi, Zigbee, Bluetooth, Sigfox, and a half dozen or more should be considered. A winner will emerge from these choices. Many products are available to build a system.

Step #3: Build or buy?

The next decision is whether to buy wireless ICs and design your own sensor nodes or purchase ready-made modules. Completed modules will save a massive amount of design and testing time. And most are pre-certified to meet emission standards. Otherwise, you will need to bear the inherent time and expense obligations. Commercial modules may be a bit more expensive, but that cost is offset by the significant reduction in design time and testing.

Step #4: Identify a power source.

As IoT rapidly grows into new markets such as health, agriculture, and building automation, new consideration is being given to the energy required to support its growth. Due to IIoT’s diversity, there’s a broad spectrum of power requirements.

A common power source for wireless sensors is a battery. Low power consumption of the module is essential to minimizing the need to change the battery more often. Some fixed nodes may use an ac-dc power supply. For some remote sensor nodes, energy harvesting may be an option. Energy harvesting eliminates the battery or power supply. It exploits a variety of methods to generate power using mechanical motion, sunlight, or some other method to capture “free” energy.

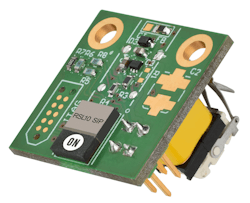

One such source is the ZF energy-harvesting switch. This is a mechanical switch that operates a magnet. When the switch is used manually, the magnet induces a voltage into a coil. That voltage is captured, rectified, and stored in a capacitor. That voltage is used to operate sensor node with a radio transceiver. Today, a state-of-the-art, cost-effective energy-harvesting switch in now available (Fig. 1).

1. Energy-harvesting Bluetooth Low Energy switch using ON’s RSL10 chip.

Step #5: Begin prototyping.

The starting point is acquiring the hardware—sensors, wireless modules, related processors, and the power source. For the software, you will need an IDE, an OS, and code unique to your application. You can seek out and collect all of these items yourself individually, and then build your unique system. But that’s disjointed, often haphazard, not to mention time-consuming. Hopefully all of the hardware and software pieces will work together.

A faster, better way is to take advantage of ON Semiconductor’s IoT Development Kit (IDK). It’s a complete integrated package of hardware and software, with multiple options, that lets you develop your own system in record time. The kit has enough flexibility to handle a wide range of applications in such fields as industrial control, healthcare, environmental monitoring, home automation, building automation, and wearables.

The heart of the IDK is a motherboard with ON’s NCS36510 SoC that includes an ARM Cortex M3 processor and related hardware. This main platform is designed to take daughterboards or shields that allow you to customize it to your own needs. Here’s a summary of just a few of the accessory boards available:

- BB-GEVK: Base board that serves as the main interface to the other boards.

- ALS-GEVB: An ambient light sensor.

- PIR – GEVB: Passive infrared sensor.

- TS-GEVB: Touch switch with capacitive sensor.

- D-STPR-GEVK: Stepper-motor driver and interface.

- POE-GEVB: Power over Ethernet

- BLE-IOT-GEVB: Bluetooth 5/Low Energy using the ON RSL 10 chip.

- US-SIGFOX-GEVB/EU-SIGFOX-GEVB: Sigfox wireless for the U.S. and Europe.

- SPS-READER-GEVK: Smart passive sensors evaluation.

Wireless Development Kits

When prototyping an IIoT system, chances are you will need to spend more time on the wireless technology selected. Prototyping kits are available for some technologies. Here are two examples from ON semiconductor.

The BDK-GEVK Bluetooth Development Kit features ON Semiconductor’s RSL10 SoC (Fig. 2). It’s a full Bluetooth 5 Low Energy radio with an on-chip ARM Cortex-M3 processor and an embedded digital signal processor (DSP). One of its key features is its very low power consumption. It’s designed to operate with dc voltages from 1.1 to 3.3 V with no required external dc-dc converter. In receive-only mode, it consumes a mere 7 mW. In deep-sleep mode, the power consumption is only 62.5 nW. An evaluation board and several accessories are available to speed and simplify testing and prototyping.

2. ON Semiconductor’s BDK-GEVK dev kit features the RSL10 chip.

Another development kit available from ON Semiconductor targets the Sigfox wireless standard. It’s a low-speed technology using frequency-shift keying (FSK) or Gaussian FSK (GFSK). U.S. versions use the 900- and 922-MHz frequencies, while the European version uses 868 MHz. The company offers multiple versions of the SoC radios and processors to meet the needs of the many different Sigfox networks. Evaluation boards and accessories make prototyping and testing fast and easy.

If you really want to slash your IIoT start up time and time to market, these IDKs will do it. Check them out yourself.

Sponsored Resources:

- Creating a State-of-the Art, Cost Effective Energy Harvesting Bluetooth Low Energy Switch

- Internet of Things Development Kit Set Up

- Internet of Things (IoT) Development Kit (IDK)

Related Resources: