This file type includes high resolution graphics and schematics when applicable.

This year is considered by many as when the Internet of Things (IoT) comes of age. Judging by the IoT introductions dominating this year’s Consumer Electronics Show, it appears the pieces are coming into place.

One would think it would be easy to come up with a novel idea and bring it to market. But how do you know that your design really works? Perhaps more importantly, how do you know that it meets government regulations? In other words, how do you debug it during development and test it to verify that the design meets industry standards and government requirements?

To find out, Electronic Design proposed a situation to two test-and-measurement companies. At Tektronix, I emailed Dorine Gurney, the company’s product planner for its Source Analyzer Product Line. At Keysight, I spoke with Jan Whitacre, the company’s Mainstream Wireless Technology Lead.

Suppose I envision a wearable product for health and fitness: How can I be sure it’s going to work in all kinds of RF environments?

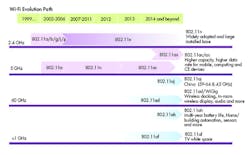

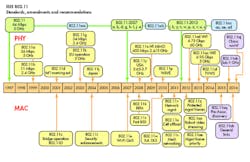

Gurney: This is not easy testing, a lot of companies are struggling with this one, even the RF IC manufacturers. The issues are being able to define multiple possible environments. Typically there will be Wi-Fi in it, but Wi-Fi can come on different channel bandwidths and in different flavors, such as 802.11b used for beacons or for traffic when older Wi-Fi devices (older computer) are expected to be lying around--but also OFDM for the more recent flavors of Wi-Fi. Interference from a microwave oven can also be in the environment, even in a corporate environment.

Another major issue is reflections and fading, because the RF waves will be combining themselves or destroying themselves, so the environment will not be uniform. So the short answer is that you can never be really sure until you test.

Whitacre: Here is a list of technologies used for medical devices. The first part of the list cites the general technologies used—or you could call them ‘off-the-shelf.’ The second set comprises dedicated technologies.

General:

• WLAN- 802.11 a/b/g/n

• Bluetooth- 802.15.1, Low Energy

• Zigbee - 802.15.4

• RFID / NFC

• Cellular- HSPA, HPSA+, LTE

• Mobile WiMAX- 802.16e

Dedicated medical:

• Inductive coupling implants

• Medical-device radio communication service

• Medical micropower networks

• Medical body area networks (MBANs)

• Wireless medical telemetry (WMTS)

RF areas also need to be tested, such as:

• Coverage range or sensitivity

• Radio spectrum/frequency

• Data rate

• Interoperability

• Power

In all of these, interference—electromagnetic interference/compatibility (EMI/EMC)—is key. EMI presents a risk of patient safety because more and more medical devices on or in patients are frequently used in environments that include broad EMI sources, such as mobile phones, tablets, and both consumer and industrial electronic products.

Also, to ensure reliability and safety, there are many medical regulatory standards.

Beyond 803.11, what are the standards?

Gurney: One of the main requirements for wearables is that they be battery-operated. Even if Bluetooth doesn’t consume as much as 802.11n, it still requires more energy than a coin cell or energy-harvesting technology could produce. That leads a designer to Bluetooth Low Energy, because one of the objectives of the standard is that it can run off coin cells. (For more information, she recommends reading DigiKey's “Comparing Low-Power Wireless Technologies.")

However, if the device requires long-range connectivity, then sub-gigahertz wireless standards are better suited. (For more information, see “Using sub-gigahertz wireless for long range Internet of Things connectivity.”)

What test equipment do I need in order to show I meet these standards?

Gurney: Every standard has different requirements; some don’t have any. For Bluetooth design, the Bluetooth SIG provides some detailed explanations in “Bluetooth Qualification and Declaration Processes.”

However, in general, to test compliance at the RF layer would require a spectrum analyzer with some vector-signal-analysis capability, although a few communications standards, such as near-field communications, might be verified on an oscilloscope.

For the upper layers of the communication stack, protocol analyzers should be used. In some cases, if a reference design is strictly followed and the profiles are not changed, then there is no need to go through the complete qualification process. On the other hand, it may be really hard to verify in a product with a wearable as the form factor, because placement of the antenna will affect the emission of the IoT product compared to the reference design.

Ultimately, the wearable product also must comply with the regulatory requirements of the countries where it will be sold. To prepare for that, we recommend a spectrum analyzer that can test up to the tenth harmonic of the main signal.

Whitacre: Focusing just on test equipment, Keysight’s Electromagnetic Professional (EMPro) electromagnetic (EM) simulation software design platform for analyzing 3D EM effects on components. Essentially, the software works with the company’s test equipment to set up and run analyses using both frequency-domain and time-domain 3D EM simulation technologies, specifically finite element method (FEM) and finite difference time domain (FDTD).

Regarding specific test equipment, spectrum analyzers for transmitter, components, and interference testing, for example Keysight’s PXA along with 89600 VSA software with high -performance measurements and 160-MHz bandwidth going all the way to 50 GHz, will cover many testing needs.

Also, the MXA signal analyzers and MXG signal generators provide broad test capability for measuring the transmitter and receivers of the devices with off-the shelf technologies such as WLAN and Zigbee.

And the N9038A MXE EMI receiver for EMI testing provides diagnostic tools for finding the causes of problems. There are also one-box testers such as the EXM for the high-speed manufacturing of these devices.

Oscilloscopes are used to test the high-speed interfaces within the chipsets.

How do I do the testing? Is it the Wild West? Are we now just at some kind of plugfest stage? Or, can we be truly analytical about compatibility?

Gurney: Again, it depends on the standard to be implemented. Bluetooth SIG and Wi-Fi Alliance, for example, are very organized and provide documents that guide you through the process to qualify a part. Actually, Bluetooth suffered bad press for manufacturer’s incompatibilities, so they have been trying this process to the extreme.

Ultimately, it depends on the wearable product. (Is it an upgrade from an existing certified product, how much it differs from a pre-certified reference design that was obtained from the wireless semiconductor supplier?) The new product designer needs to do some internal testing to make sure the new device has a chance to be compliant and then go to one of test houses that have been approved by the SIG or the Alliance.

What about FCC certification?

Gurney: Yes, this needs to be done before being able to sell the final product. In some countries, there are some dispositions in which this certification can be accepted if it has been embedded already has some modular level certification. Otherwise, certification costs on the order of $1,000 per day. Testing must be performed in an accredited test house, and may take several days.

Could a designer simply use an off-the-shelf RF module?

Gurney: RF module manufacturers are working to get the module smaller and smaller—some of the latest ones are below 100-mm square and designed to be surface-mounted.

It will depend on the wearable, really. A big decision in the design will be the antenna. Tektronix offers a suite of mixed-domain oscilloscopes and signal analyzers that can be equipped with software modules to test various wireless-connectivity approaches used in the Internet of Things.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Don Tuite

Don Tuite (retired) writes about Analog and Power issues for Electronic Design’s magazine and website. He has a BSEE and an M.S in Technical Communication, and has worked for companies in aerospace, broadcasting, test equipment, semiconductors, publishing, and media relations, focusing on developing insights that link technology, business, and communications. Don is also a ham radio operator (NR7X), private pilot, and motorcycle rider, and he’s not half bad on the 5-string banjo.