Optoisolators (also known as optocouplers or photocouplers) don’t radiate a lot of component glamour, but they are critical interface components in many systems. They offer multiple problem-solving uses, including “breaking” ground loops and providing galvanic (ohmic) isolation between a system’s functional blocks.

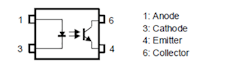

Such attributes are needed in arrangements where high common-mode voltages affect system connectivity, or when a component failure could put unacceptable high voltage onto low-voltage circuits or even endanger users. These functionally simple, diminutive components offer a high level of isolation—typically several thousand volts—in a tiny package, as clearly demonstrated by various standardized tests. Among other key specifications is the collector-emitter voltage (VCEO), a parameter that derives from their underlying transistor-like structure and nomenclature.

Recognizing this, the TLX9188 infrared optoisolator from Toshiba Electronic Devices & Storage Corp. supports a collector-emitter voltage up to 200 V (minimum) (see figure). This is the highest VCEO value Toshiba offers in an automotive optocoupler and 2.5X higher than its existing optocoupler, the TLX9185A. The 200-V rating makes the TLX9188 a good fit for isolation of communication signals in automotive applications such as hybrid electric vehicles (HEVs) and battery electric vehicles (BEVs or EVs).

The device offers a current transfer ratio (IC/IF) from 50% (minimum) to 600% (maximum). The TLX9188 is housed in a very small and thin 4-pin SO-6 package measuring 3.7 × 7.0 × 2.1 mm to meet the needs of densely packed designs. Despite this small size, it features input-to-output isolation voltage of 3,750 V rms (minimum). It’s fully qualified according to AEC-Q101 for automotive applications and specified for operation from −40 to +125°C.

Despite its brevity of just eight pages, the TLX9188 datasheet is complete with specification tables as well as graphs showing performance of key parameters with respect to temperature, voltage, current, and time.

Note that even if you don’t have an immediate need for this type of component, Toshiba has a very informative, highly readable 20-page application note “Safety Standards for Photocouplers.” This note explains frequently used terminology along with examples from component and equipment safety standards for photocoupler products. Given the depth, intensity, and sheer volume of these regulatory standards and mandates, any insight in this area is appreciated.